'Significant improvement in both capacity and efficiency'

Inther Group, the international hybrid systems integrator for intralogistics solutions, has been involved in the development and optimization of HEMA's e-commerce distribution center in Utrecht for fifteen years. During the customer day on Wednesday, May 14, professionals from the logistics sector got a unique look behind the scenes of HEMA's logistics operation.

At the e-commerce DC in Utrecht, from where HEMA delivers to online customers in several European countries, CEO Martijn Herder of Inther Group welcomed attendees to the customer day. He explained that, as an international hybrid systems integrator, Inther Group - headquartered in Venray - specializes in automation solutions for picking, packing, storing and sorting goods in warehouses worldwide. "We offer customers not only automation solutions, but also smart software and in-depth data analysis. Inther works according to the turnkey principle: fixed price, fixed delivery date, clearly defined scope. After delivery follows a service agreement for preventive, corrective and, increasingly, predictive maintenance. Using our self-developed software, data is analyzed up to two years back, revealing trends and helping to optimize system efficiency."

Software is the beating heart of any system at Inther, the CEO emphasizes. "We supply PLC control as well as our own Warehouse Control Systems, and in some cases also the Warehouse Management System. Our own Inther LC software thereby ensures optimal control of all logistics processes, from inbound to outbound." Herder adds that each project starts with a thorough analysis, followed by simulations. "That way we can ensure that the system actually works in practice as designed."

Strong growth in picking capacity

Finally, Herder shows some examples of high-profile intralogistics projects, including for Picnic, Zeeman, Coolblue and BMW. The innovative A-frame solution used by a 3PL company in the US for automated order processing of air fresheners is also discussed. Each of these are examples of intelligent, sustainable and above all customized logistics systems, tailored to the unique challenges and ambitions of the customer, according to the CEO.

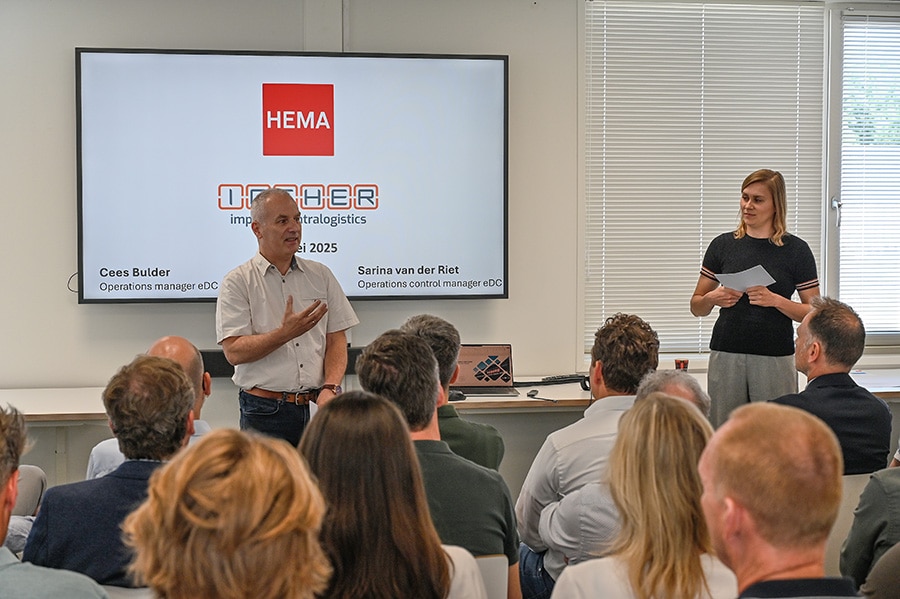

After this introduction, it is the turn of Cees Bulder, operations manager of HEMA's eDC. The core of his presentation is the representation of HEMA's e-commerce history in a clear timeline. HEMA's partnership with Inther Group dates back to 2010, after which the eDC was automated step by step. "Although initially costly, all the improvements and investments in the logistics process have more than paid for themselves through greater accuracy and efficiency," he enthusiastically notes.

Before the attendees embark on the extensive tour of the e-commerce DC, his colleague Sarina van der Riet, operations control manager eDC, elaborates a bit more on the automation and expansion projects that Inther Group has implemented at HEMA starting in 2017. "As a result, in recent years the daily picking capacity has grown from 80,000 to 210,000 items, orders are processed more efficiently and the distribution center has been future-proofed for further e-commerce growth," she concludes.

Miniload system

In the subsequent tour of HEMA's e-commerce DC, visitors will see firsthand how Inther Group's hybrid systems work together seamlessly to support an efficient customer journey. What immediately stands out is that HEMA's intralogistics are a textbook example of scalability and flexibility. This starts immediately with a mini-load system with space for 13,000 plastic bins for bulk stock, which has significantly reduced reach truck traffic. Also drawing much attention is the shuttle system with 33,000 totes and 75 shuttles, which can transport 2,400 totes per hour to the eight Good to Persons order picking stations. Inther also supplied a carton erector, label applicators, Automated Document Inserters (now phased out again), the DPS (Dynamic Picking System), carton closers (B+ machines) and the conveyors connecting all the machines. It becomes clear that Inther did the complete automation project.

A significant part of the optimization comes from Inther's software. For example, smart software allows HEMA to distribute the workload evenly across the system, leading to better capacity utilization and a reduction in mispicks.

The increased storage and order capacity is partly due to the implementation of miniloads, the shuttle system combined with the GTP and the DPS, which allows order pickers to work more efficiently by handling multiple orders simultaneously. The Warehouse Control System for integration and control of the whole is also from Inther. Visitors were visibly impressed with how the automation of the HEMA e-commerce DC has led to a significant improvement in both capacity and efficiency.

Grip on supply chain

This much is clear: Inther has developed a future-proof intralogistics system for HEMA that continuously evolves with changing customer requirements and market demands.

Before drinks and snacks can be enjoyed, logistics consultant Jeroen van den Berg, author of the book "Highly Competitive Warehouse Management," will give a fascinating presentation on important trends in warehousing. In a world where supply chains are becoming increasingly complex and unpredictable, companies are looking for a grip, he says. "Too much happens outside of systems. That leads to errors, frustration and delays." Based on more than 30 WMS projects he has been involved in over the past few years, he distills six trends that should prepare warehouses for the future, namely: end-to-end supply chain, digitization, robotization and mechanization, sustainability and rationalization, cloud software and last but not least artificial intelligence. Van den Berg sees the future optimistically: "With smart systems and realistic processes, you regain control and improve the customer experience."

During the convivial afterglow, all those present agreed: this customer day not only gave them insight into the cooperation between HEMA and Inther, but also showed the power of integrated, modular and data-driven intralogistics solutions. The common thread? Logistics is not a standard solution. Only through cooperation, knowledge sharing and the courage to innovate will companies like HEMA and their partners remain sufficiently agile in an increasingly complex supply chain world.