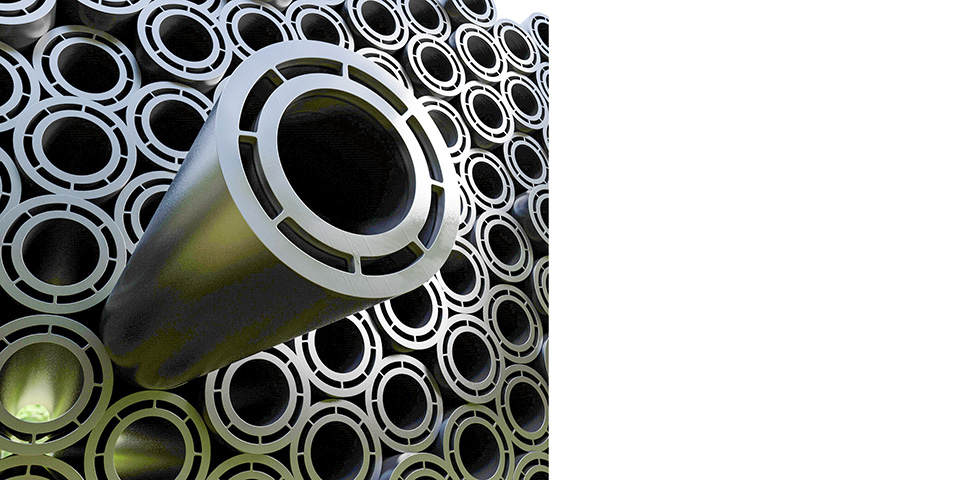

Sewer made with double-walled pipe system

The large Brombachsee is located about 40 km south of Nuremberg. The lake was commissioned in 2000 and houses one of the largest dams in Germany, both in terms of surface area and storage volume. Due to the increasing number of tourists, in February 2018, 20 floating houses were built on the shores of the lake. In addition to various other equipment options, each house has a well-coordinated plumbing system. The sewer pipes were welded from the double-walled AGRU Poly-Flo pipe system, made of PE 100-RC.

The wastewater is safely transported to a mainland collection tank via a wastewater pressure pipe in Lake Brombach. From there, the collected wastewater is forwarded to the sewage treatment plant. Special precautions must be met when constructing and operating sewers in water catchment areas such as Lake Brombach. In this zone, pressure pipes with a very high risk potential must be double-walled. Another challenge in the planning and execution of the project were the different water levels. This is because the pipes connected to the pontoons, which serve as a floating foundation for the houses, extend to the mainland. For this reason, the pipeline had to be flexible enough to compensate for the difference in water levels, which can be up to 8 m high.

In the riparian area, a 10 m wide section must be traversed by horizontal directional drilling.

Troubleshooting

FRANK GmbH succeeded in providing an economic and technical solution to all these problems with the AGRU double-walled pipe system "Poly-Flo", made of the thermoplastic material PE 100-RC. A double-walled pipe extruded as a mono-strand, providing high system security, characterizes the Poly-Flo piping system. Possible leaks on the inner pipe can be detected in the existing annulus by the leak detection system located there. The outer pipe is used to stop the current flow medium from entering the lake. For leakage monitoring of the double pipe system, it was decided to use an overpressure leakage system. In the overpressure process, both walls of the double pipe system are monitored for leakage. The monitoring pressure is operationally higher than any other internal or external wall pressure, so a drop in pressure indicates leakage.

A permanent monitoring pressure of 1.5 bar is in operation in the annulus of the Poly-Flo piping system. The pipes and fittings of this extremely compact double-wall piping system are fully extruded (pipes) or cast (fittings) in a single manufacturing process. Continuously extruded webs make alignment of the inner pipe and outer pipe easy. An advantage of the continuously extruded webs is that the pipes can be separated at any point, when required due to isometry. Because of the significantly smaller component dimensions, easy assembly is possible even in tight spaces. The joining of the individual double-walled pipe components was performed by simultaneous welding. Since in this process the inner and outer pipes are simultaneously welded in one step, this was an optimal solution of processing from both an economic and a processing standpoint. A double-walled pipe made of PE 100-RC has high flexibility, which allows the large height difference between the transition point on the mainland and the pontoons to be overcome without additional fittings.

AGRU Kunststofftechnik extrudes the double-walled waste water pressure pipe Poly-Flo as a monostreng.

Why PE 100-RC?

PE 100-RC was chosen as the material of choice. The innovative PE 100-RC material (resistant to cracking) has a much higher resistance to slow crack growth than PE 100. Because of this increased resistance to stress cracking, pipe systems made of PE 100-RC can also be used for sand-bank-free laying. In addition to its corrosion resistance to the surrounding seawater, PE 100-RC's resistance to changing temperatures in Lake Brombach was an advantage over other materials. Since sewage water can also contain larger solids components, the very good abrasion resistance of PE 100-RC was also a decisive factor in choosing the material.

In a water catchment, the highest safety regulations apply to wastewater disposal. AGRU's Poly-Flo pipeline is equipped with a leak detection system in the annulus.

Implementation

The pipes, which serve as the connecting sewer between the individual houses, are made of Poly-Flo pipes PE 100-RC OD 90/63, manufactured by AGRU Kunststofftechnik. After assembly, the collected wastewater from all floating houses is pumped to the main line. The main pipe made of Poly-Flo pipe PE 100-RC 160/110 and the connecting pipes were welded directly on site. Since there is a 10 m wide public pedestrian area between the lake and the onshore wastewater reservoir, it was necessary to go through the ground. The so-called horizontal directional drilling (HDD) method was used. To slowly sink the pipe section to the bottom of the lake, it had to be made heavier. This was done by filling the pipe with water and adding additional pipe clamps embedded in reinforced concrete. The project was realized in the period planned for it. The "Floating Houses" were very popular soon after their completion, offering tourists comfortable accommodation on the amazing Brombachsee.