Lantech packaging machines improve efficiency and accuracy in e-commerce and logistics environments

Lantech, manufacturer of end-of-line packaging machines, offers a range of innovative packaging systems to provide the logistics and e-commerce industry with fast, flexible packaging machines that optimize the shipment of goods through their efficiency and accuracy.

Efficiency with rectangular boxes in a wide range of sizes

The C-1000 Case Erector is known for its efficiency and rectangular boxes. It produces up to 30 boxes per minute with flexible sizes ranging from 200 x 150 x 150 mm to 500 x 325 x 520 mm. Users receive perfectly rectangular shipping boxes that offer maximum stability and are ideal for transportation.

The box erector produces 90-degree angles regardless of corrugated board type, varying temperatures or humidity and varying plano sizes. Users are assured of rectangular shipping boxes that are ideal for the logistics chain and offer maximum stability. Depending on customer preference, the bottom of the box is sealed with hot melt or tape.

Space-saving multifunctional box erector

However, the C1000 carton erector can also be expanded with 2-3 or 4 magazines, calling it a multi-purpose carton erector. The MFC increases the flexibility of the packaging process by allowing boxes of different sizes to be set up with just one machine. This compact solution has up to four warehouses that can be individually configured and filled during operation. This allows different box sizes to be produced on one machine without the need for conversion or production downtime. The MFC saves valuable production space compared to using multiple conventional box erectors with one magazine. Even more space is saved thanks to the central output point for the boxes, as there is no need to combine several conveyors into one output system.

Choice of many box sizes

The MFC can handle cartons with dimensions from 200 x 150 x 150 mm to a maximum of 620 x 450 x 650 mm. The maximum throughput is 1080 boxes per hour. The MFC is also equipped with Lantech's Total Control System. This provides precise control during set-up, resulting in perfectly square boxes. These square boxes prevent jamming and are easier to load, stack and palletize.

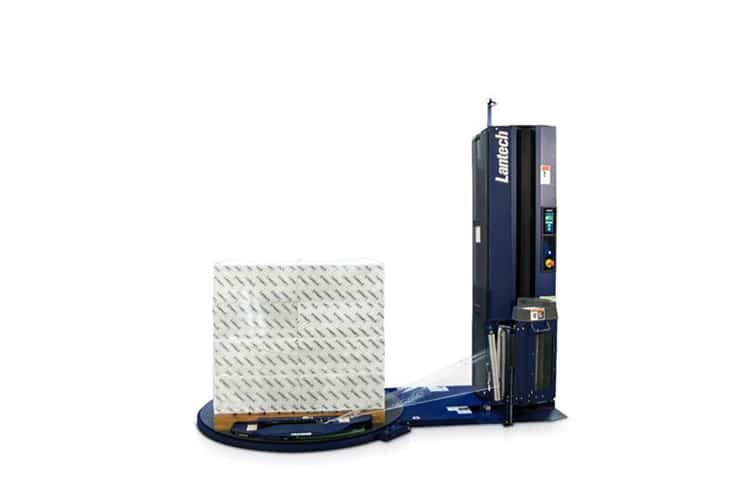

Securing cargo on pallets

For professionally securing loads on pallets, Lantech offers an efficient packaging solution with the QL400XT semi-automatic pallet wrapper. This machine shortens any wrapping process by two minutes per cycle by automatically attaching the film to the pallet and cutting it after wrapping. This is made possible by the patented ‘XT Cut and Clamp’ function, which is purely mechanical and requires no compressed air or electricity.

Another advantage is the intelligent ‘Load Guardian’ control system. The system creates special profiles with the correct tension for common loads. This saves time and prevents operator errors. The QL-400XT stretch film wrapping machine can process up to 35 pallet loads per hour, with a maximum diagonal of 1830 mm and a maximum height of 2030 mm. The processed film can be pre-stretched up to 300 percent.

Visit Lantech from March 24 to 26 at the Logimat in Stuttgart, Germany hall 1, booth B72, or from April 14 to 16 at the Empack Gorinchem booth E24 and find out how their automation solutions can optimize your packaging processes.