Vision technology has never been easier to integrate

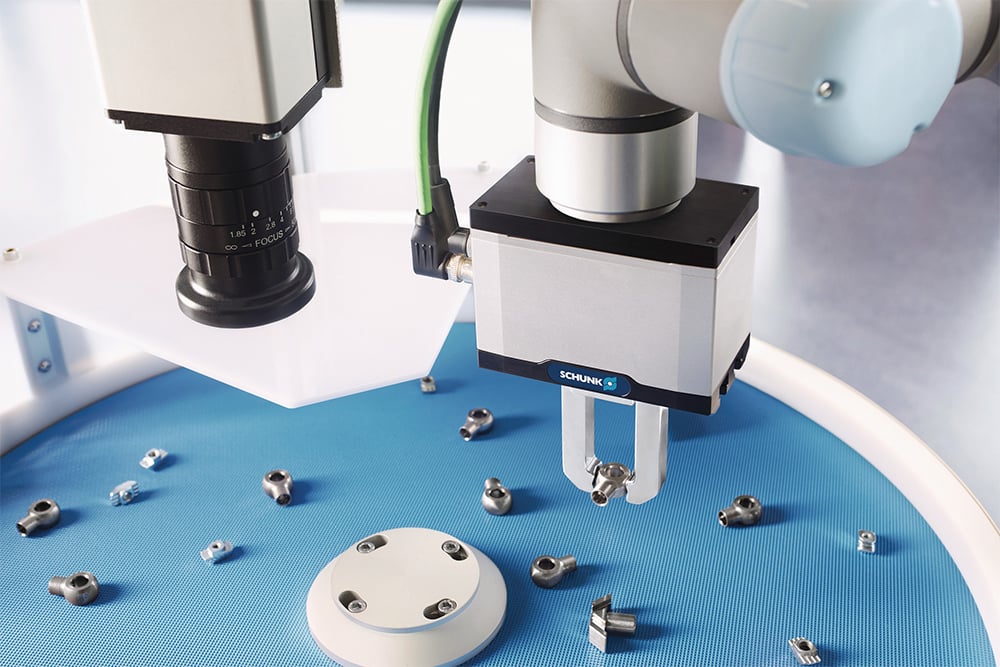

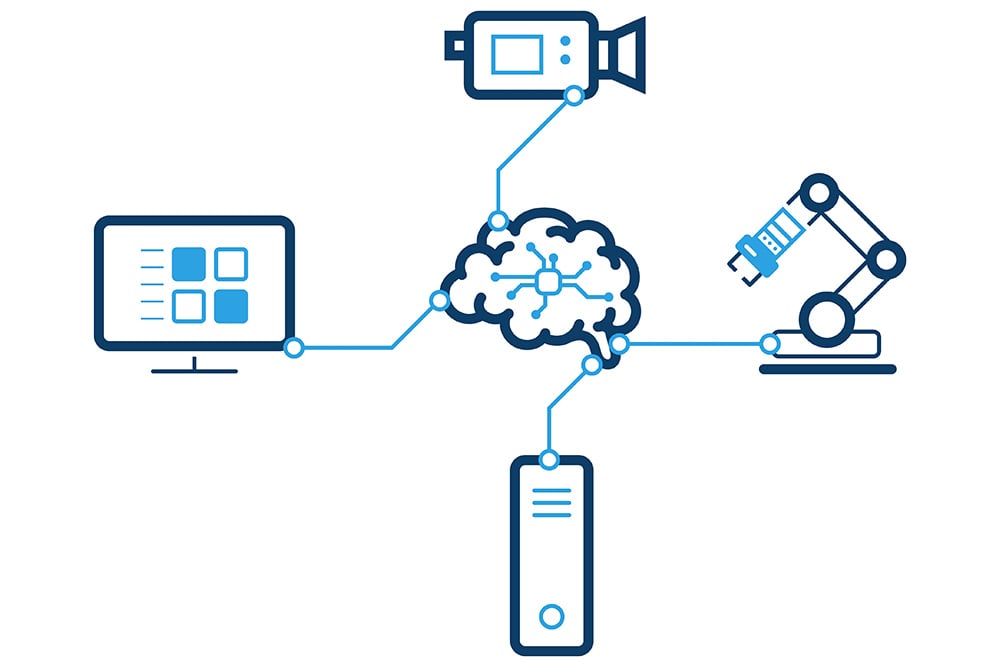

The hardest part about vision solutions? Detecting the objects and determining the right gripping position. SCHUNK therefore turned the tables and just departed from its expertise in gripping to lower the threshold for vision technology. With the 2D gripping kit, consisting of camera, gripper, an industrial PC with the AI software developed by SCHUNK and a plug-in for the robot controller, you get an integral solution that makes it much easier to start automated object gripping today.

Vision is the future of automation. But vision technology can be quite complex, especially to achieve perfect synchronization between the camera and the gripper. That does require some programming knowledge to get completely right. "For complex applications, that investment might pay off, but a lot of potential for more efficient work remains untapped. With that in mind, SCHUNK went to work. The core of the 2D grip kit this time is not the hardware but the software developed by SCHUNK.

Based on artificial intelligence, it will recognize objects and determine the correct position, regardless of color and under varying light conditions. With this we really distinguish ourselves on the market," Kevin Stevens, application engineer at SCHUNK, summarizes the operation. "Which gripper the customer wants to use basically does not matter. It can be either electric or pneumatic."

Application set up in one day

The applications are numerous: pick-and-place, machine loading ... Everything where 2D vision can add value. It is the knowledge of gripping that SCHUNK has put into the 2D gripping kit that makes the difference. Due to the intuitive, user-friendly nature of the software, an integrator without extensive experience in or knowledge of vision technology can still easily integrate it into applications.

"Installing the kit and teaching it to grasp objects can be done in one day. In classic applications, this would otherwise take a week for a programmer. If you do run into problems, there are various help functions - such as tips and tricks and video tutorials - for each step in the software. So you can quickly get back on track. The integration of the kit is done using a plug-in that is compatible with the common robot brands and PLC blocks," Stevens adds.

Keep on developing

The 2D grip kit has been on the market for a year and a half now. During the last edition of Indumation, this newcomer could count on a lot of interest at the SCHUNK booth. Kevin: "Especially the ease of use appeals to integrators. They see the demand for vision solutions increasing and, thanks to the 2D grip kit, they can now add that to their offerings without having to bring additional knowledge in-house. The developments are not at an end, by the way. There will continue to be updates to improve performance and get a wider playing field." Second strong asset in this story is SCHUNK's reputation. "We are known as a leader in clamping and gripping. The quality that customers are used to from us, we now extend to the software."

Validation tests

Still, if customers want absolute certainty about whether and exactly how the vision solution will work, we can conduct validation tests in advance. "That way there is no risk. They know even before the investment if they have a go. This is done at the SCHUNK CoLab in Germany. But we can always visit with the Belgian team for a demo without any obligation. We also perform the first-line service during installation and afterwards ourselves," Kevin concludes.