Safe disconnection full hydraulic quick coupler

The full-hydraulic quick coupler, once you've tried it you don't want anything else. German specialist Lehnhoff Hartstahl GmbH has been supplying its own successful line of full-hydraulic quick couplings for heavy industry with the Variolock VL 100-250 for many years. They work quickly, simply, reliably and, above all, safely. The latter is partly due to the special drainline.

We asked Arthur Polak of Demtech from Zoeterwoude what is so special about that drainline: "At Lehnhoff, they came up with the safest way to disconnect. When the system is connected, all couplings are under working pressure. Disconnection is then not possible without problems. The drainline is in the stroke of the coupling. Because of the conical key, it is released gradually. So you can uncouple 'under pressure,' because of this no extra function needs to be built up." Not only does this allow safe disconnection, this approach also increases the life of the couplings. Arthur: "This approach therefore saves costs."

High flow without return pressure

Most popular are the full-hydraulic quick couplings for demolition cranes of say 17 - 40 tons. "Those use the same adapter plate SW 21/25 and that saves on costs. We are talking in particular about the Variolock VL210 and VL250, while the VL100 is mainly used on the more compact excavators. In the heaviest class of machines, the series continues with the VL400 and the VL1000 for cranes up to 130 tons," Arthur said. "A special feature at Lehnhoff is the high oil flow (550 liters) without build-up of return pressure. As a result, less heat is developed, thus less cooling is required and work can continue longer. Longer-term wear is also less. The hydraulic unit and the proven original Lehnhoff quick coupling form a compact unit."

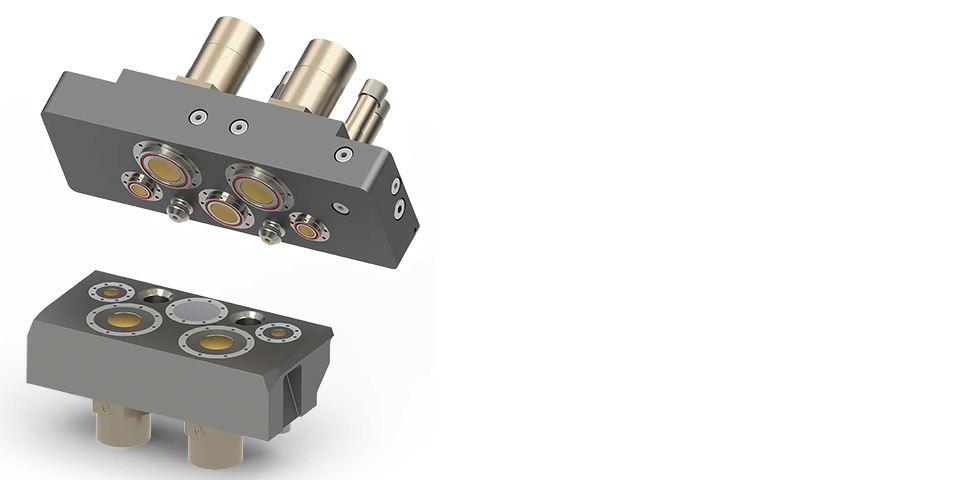

Detailed view of the coupling system at the Lehnhoff full-hydraulic quick coupler.

Time is real money

We then asked Arthur, why there is increasing demand for fully automatic quick couplers. His answer is sobering: "Young people are taking a different approach, a little lazier but also smarter. If you want them to work on an excavator, you can no longer make them hammer out and drive in pins and connect hoses by hand. For them, the full-hydraulic quick coupler is as normal as their cell phone." But there's more: "Employers are doing different math these days. Time is really money and then on a big demolition job you can't stand for half an hour toiling to change a hammer or scissors on your demolition crane. With the full-hydraulic quick change is just money to be made. No more waiting trucks, no last hour wasted, just change from hammer to pulverizer and keep working. That idea."

Strong position in Benelux

Demtech BV from Zoeterwoude has taken a strong position in the demolition and recycling industry in the Benelux with some well-known brands. Lehnhoff Hartstahl is not the least of these. The company is based in Germany's toughest area, the Black Forest. Hence their motto: "If our products work here, they work anywhere in the world." And it must be said, that famous German quality is well reflected in the Lehnhoff program of full-hydraulic quick couplings.