Plastibac supplies personalized load carriers to customization company OptimaT

In the previous issue of this magazine, we introduced you to Plastibac, a West Flemish family company specialized in plastic load carriers for storage, logistics, waste management, facility and packaging. These solid and reusable solutions are in great demand by both Belgian and foreign customers from various sectors. In this issue, we highlight the collaboration with the customization company OptimaT from Lichtervelde.

"Since our establishment in 1982, Plastibac has grown into a solid European player, with customers in our neighboring countries, Austria and Switzerland," Brecht Corty, account manager at the West Flanders family-owned company since 2015, opens the conversation. "For a lot of Belgian and foreign entrepreneurs, we are the trusted supplier of high-quality plastic bins, containers, pallets and numerous other load carriers. From the smallest rack bin for small hardware to high-volume boxes for storing large items: we are at home in all markets."

Plastibac not only offers a wide range of packaging solutions. The team also excels in short lines of communication with customers, customized offerings and fast delivery of ordered products. "Our RRR concept - reuse, reduce, recycle - is also high on the agenda in our company," said Brecht. "When a product reaches the end of its useful life, we from Plastibac offer our customers the opportunity to give this product a second life."

Personalized printing

Another service that Brecht wants to highlight is the possibility of custom printing purchased plastic packaging. "By personalizing packaging, you convey a commercial message to the outside world and your company name becomes extra visible. We offer various printing options, from hot-stamp - with or without cliché - to screen printing and IML. This stands for 'in mold label' and is a technique where the print is molded into the plastic product during the production process."

Inspiring collaboration

One of the customers who gratefully uses the extensive Plastibac offer and the accompanying services is OptimaT from Lichtervelde. "The cooperation with OptimaT has grown organically," Brecht looks back. "After a few exploratory sales visits, the management decided to join forces with Plastibac for the supply of different warehouse bin types, in all sizes and colors. With 650 employees and diverse activities - from powder coating department to green service and from electrical department to painting service - OptimaT is a very grateful customer for us. Their employees work in a structured and well-organized manner, so they need a clear storage system of materials and machines. Furthermore, OptimaT continuously pushes us to think along with them about innovative storage and packaging solutions. The fact that we operate in the same region is an added bonus. After all, we highly value a local approach."

Brand new high-rise warehouse

Under the impetus of general manager Hein Moerman, the OptimaT team is tackling things thoroughly in terms of warehousing and logistics. The brand-new semi-automatic high bay warehouse with six thousand pallet spaces is a good proof of this. "We don't automate to save employees, but to remain competitive and create follow-up work," Hein says. "In the future, by the way, we want to continue to focus on storage of customer products. Our new high bay warehouse is 5,500 square meters. It includes two 16.5-meter fully automatic Modula cabinets. The tallest in the Benelux."

Euronorm stacking bins

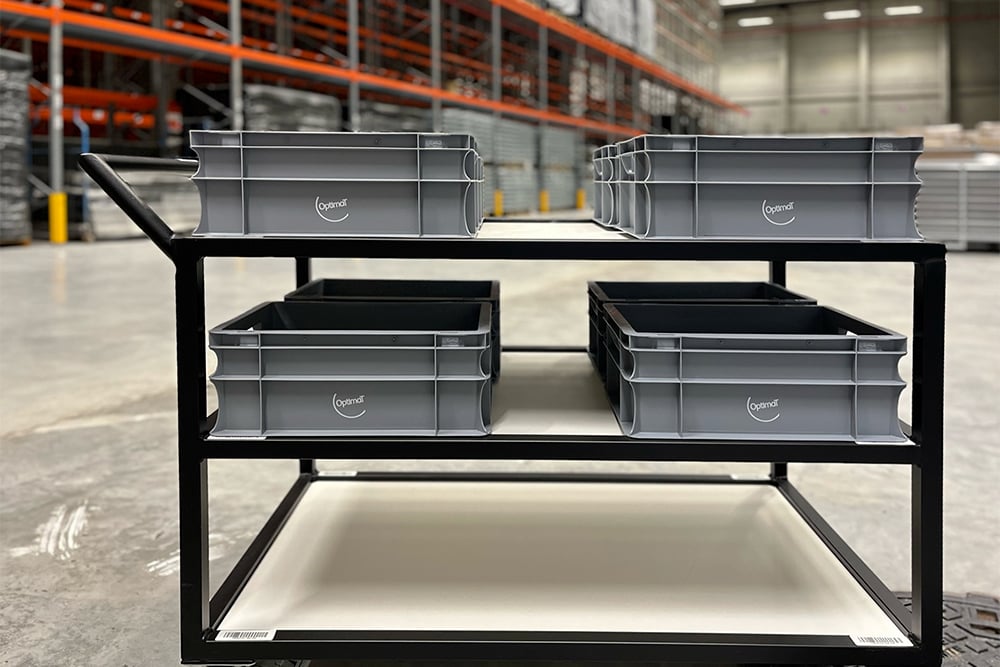

Plastibac's QUBB Euronorm stacking bins - printed with the OptimaT logo - are indispensable work tools for employees.

"The drawers of the Modula cabinets measure 480 by 80 centimeters. Different bin sizes fit in them. OptimaT currently has some 2,800 QUBB Euronorm stacking crates in use. The crates are ideal because they are sturdy and have uniform standardized dimensions, and we replenish them as needed. OptimaT also uses bins for their internal transports, for which, incidentally, they have manufactured their own rolling carts. We have also printed these bins with their company logo," concludes Brecht.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Plastibac NV.

Contact opnemen

Contact opnemen