Stöcklin strengthens presence in Benelux with sustainable, future-oriented end-to-end intralogistics solutions

The Benelux market is not new territory for Stöcklin, but rather a strategic growth area. The Swiss family company, headquartered in Laufen, can look back on more than 90 years of experience in the development, production and implementation of customized intralogistics solutions. With this, it intends to pursue an even stronger course in Belgium, the Netherlands and Luxembourg in the future.

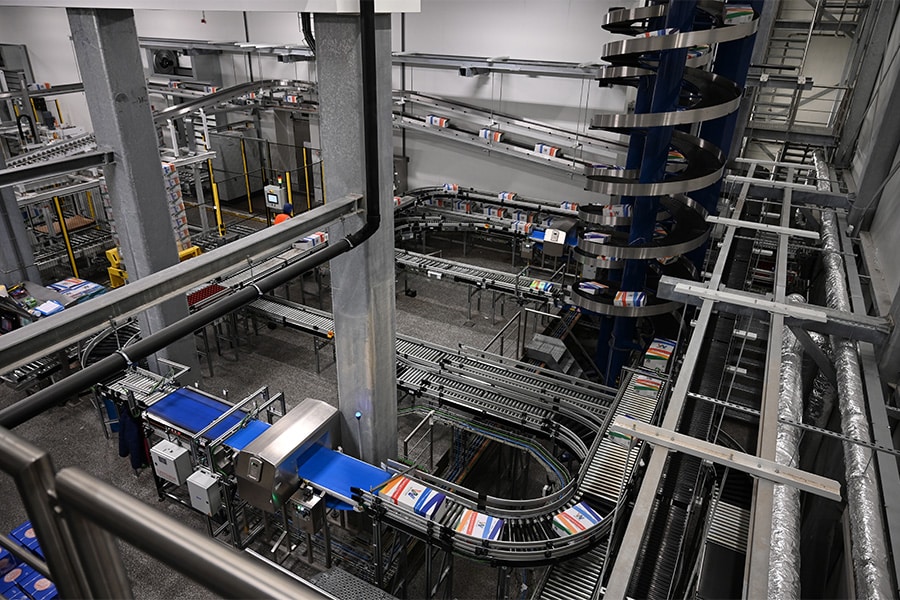

Successful projects such as the fully automated shuttle solution for the Luxembourg food wholesaler La Provençale (in temperature-controlled logistics) or the ever-expanding automated high bay warehouse and conveyor technology at Ausnutria in the Netherlands prove that the approach works: Swiss quality, technological expertise and years of partnership-based cooperation.

Local presence

Guus Elbers has been providing significant impetus for further expansion since 2024. The experienced industry expert has more than 15 years of experience in material handling and knows the requirements of the Benelux market firsthand. As sales manager Benelux, he actively drives expansion and ensures that existing customer relationships are deepened and new projects are successfully launched. "We have built a solid installed base in the Benelux - now is the right time to take the next step," Elbers explains: "The market is innovative, demanding and focused on sustainable solutions - this is exactly where our strength lies."

Everything under one roof

The heart of Stöcklin beats in the Technology Center at the headquarters in Laufen. Here, all intralogistics solutions are planned, designed, produced and tested under one roof. And then installed at the customer's site. From the initial needs analysis and detailed planning to mechanical and electrical production.

The portfolio ranges from robust material handling equipment - from hand pallet trucks to highly complex autonomous transport systems - to intelligent software solutions for controlling warehouse and material flows and customized, turnkey automation projects. This is complemented by long-term services that ensure reliable operation throughout a system's life cycle and include targeted modernization steps when necessary.

Innovative, sustainable, future-proof

Stöcklin stands for innovative, sustainable and future-proof end-to-end intralogistics solutions - all from a single source. The basis for this is distinctive planning competence: with data-based analyses, performance, energy efficiency and scalability are precisely calculated as early as the concept phase. This creates solutions that not only meet current needs but also future requirements.

Sustainability is firmly embedded in the company strategy - from energy-efficient drives and resource-saving manufacturing to sustainable systems that can be upgraded over decades. "Our systems are designed to grow with customer needs," Elbers explains.

After-sales service as a success factor in Benelux

Stöcklin's established after sales service is an important part of the company's long-standing success in the region. With an experienced on-site team, maintenance, spare parts supply, system optimizations and expansions are carried out quickly and reliably. This proximity makes it possible to keep breakdowns to a minimum, keep system availability permanently high and implement modernization measures without long downtimes. Customers in the Benelux region appreciate this continuous support, as the cornerstone of often long-term partnerships.

LogisticaNext: A practical look behind the scenes

At this year's LogisticaNext in Utrecht, Stöcklin uses an interactive presentation tool to show how projects are created, from needs analysis to system planning and commissioning. She shows how existing systems can be adapted to changing requirements through targeted measures. A special program component on the second day of the exhibition (from 10:45 - 11:15 a.m.) is the presentation of a case study, together with Ausnutria. What began in 2017 with a high-rise warehouse has expanded several times over the years. For example, two AGVs were recently commissioned and there is talk of expanding the existing high-rise warehouse. "This is exactly how we want to work together: no single orders or quick fixes, but exploring and exploiting the possibilities together to achieve the best possible result," explains Guus Elbers.

Would you like to learn more about Stöcklin's end-to-end intralogistics solutions? Then visit the LogisticaNext from 4 to

November 6, 2025 at Jaarbeurs in Utrecht.