Modularity and open interfaces make combining easy

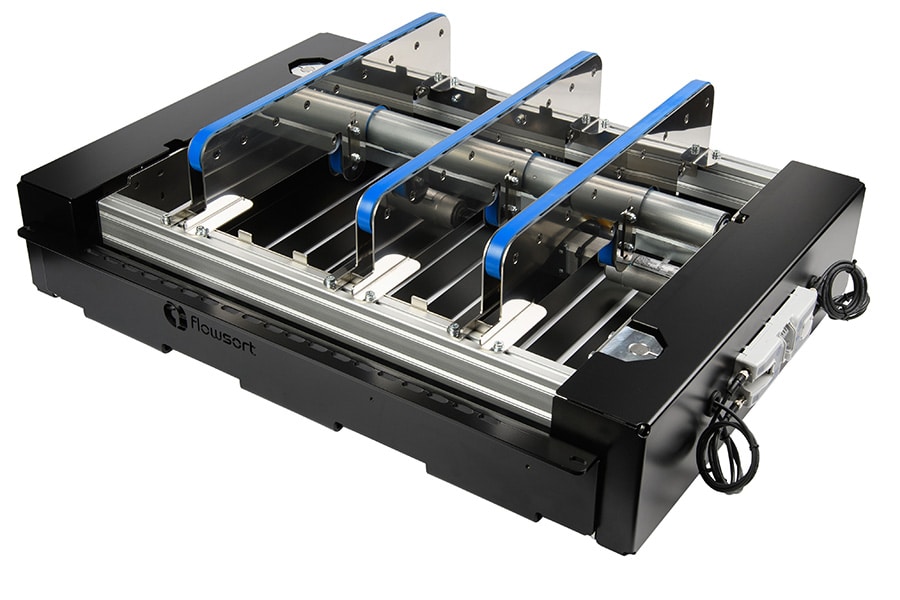

Short lines, fast switching, but also: being sure that the product works as it was intended. That, in a nutshell, is what the young company Flowsort does, says sales director Benelux Sander Wijn. "We supply proprietary modular systems for intralogistics applications."

From Venlo, Flowsort now serves companies worldwide. The products, including diverters, sorters and rollers are delivered via integrators and interfaces to end customers, including parcel companies and manufacturers. Most of these end customers can still be found in the Benelux, but the company is also growing rapidly outside the Benelux. Underlying that growth, according to the sales director, are two important aspects. "Our products are modular and we work with open interfaces. The big advantage of that is that all our solutions can easily be combined with other systems."

Ninety degree transducer

Flowsort is growing under the wings of the global FATH Group, a company with 12 offices and headquarters in Germany. Says Wine, "In 2020, FATH acquired us and that was the prelude to the current rapid growth." At the start, the company focused mainly on diverters and rollers. "Recently, we added a new product to that." Wine is talking about the X-Flow 90, a ninety-degree diverter. This system helps companies that want to transfer products ninety degrees. In doing so, the product stops on the short side and exits on the long side. Yet the front of the product always remains the front. "This is ideal for companies that need to sort out packages, boxes or crates and where precision is essential but speed is somewhat less important."

Demolin

The company's main aim is to provide customers with solutions that can be seamlessly integrated and at the same time do exactly what was thought of beforehand. For this reason, there is a demo line in Venlo where a customer can always verify that what the company wants is possible. "Of course we can also demonstrate this digitally, but sometimes physical is just a little bit better," he says. There are few limitations to what Flowsort can provide. If there is one, it is that the dimensions of an item must be larger than 80 by 80 millimeters. "Other than that, we serve a huge variety of businesses, from postal to agricultural companies and even cosmetic product suppliers."

Limit downtime

Something many companies today also appreciate is that Flowsort allows customers to scale up and down. "Our systems are modular and easy to adapt. The latter is nice, for example, if limiting downtime is important. Our diverters and sorters already have hardly any downtime, but if it's necessary to replace a part or adjust something, it's done in no time. Installing a new diverter takes fifteen minutes at most, replacing a wheel five minutes at most." For two companies that wanted to avoid downtime at all costs, the choice of Flowsort was thus a logical one: Nedlin and Trans-o-flex. "Some companies pick up maintenance themselves, if help is needed then our integration partners take it on."

'Want to become market leader'

Flowsort's ambition is great. Wine: "We want to become the market leader." He expects the modularity and versatility of the diverters complemented by the open interfaces to help achieve that goal. "A customer has to be sure that our solution works, so we do everything we can to achieve that. And sometimes simplicity or a small adjustment of a parameter is enough for that."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Flowsort .

Contact opnemen

Contact opnemen