Modern sorting systems offer postal and parcel sector efficiency opportunities

The postal and parcel sector faces major challenges: tight labor markets, growing volumes and changing consumer behavior. According to Bert van Willigen, managing director of BEUMER Group Benelux, the solutions lie not only in working harder or hiring more people, but especially in smart intralogistics systems. "Doing more with existing systems offers opportunities. Yet you only really make a difference with technology that not only sorts, but supports complete processes."

BEUMER Group has been developing systems for the logistics chain for decades. Whereas in the past it was mainly about speed and capacity, the requirements are now broader. Companies are looking for flexibility, ergonomics, insight and cost control. Van Willigen: "Our solutions sort, buffer and sequence so that parcels end up in a delivery truck or lorry in the right order. This increases capacity, but above all reliability towards consumers."

Pouch Sorter as an example

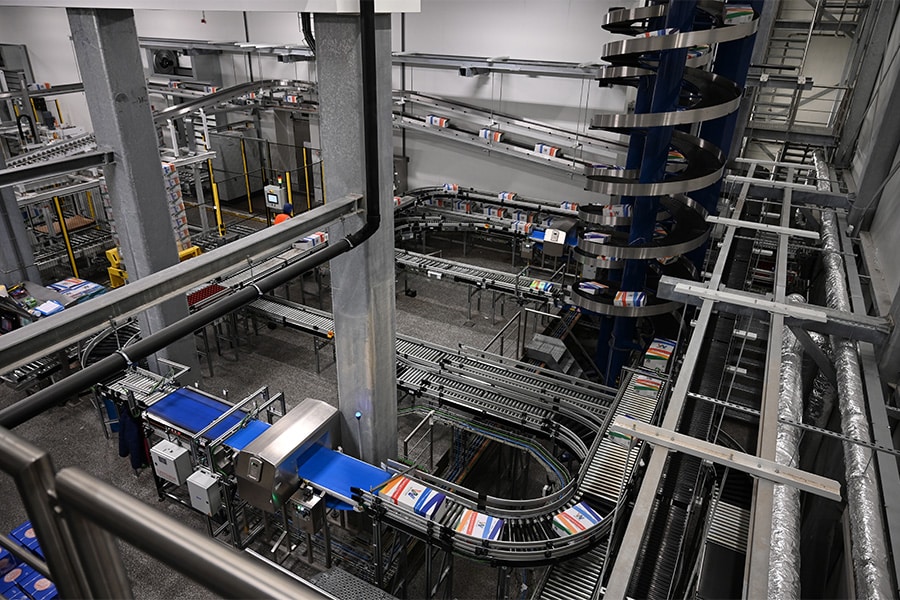

One of the systems BEUMER is showing at Parcel + Post Expo in Amsterdam is the Pouch System. The principle is that parcels or products can not only be sorted, but also temporarily stored. Because the system hangs inside the building, the available space is used optimally. "You can also play with the timing of shipments," Van Willigen explains. "Companies can decide whether something goes immediately, or whether it's smarter to wait and there's the option of processing packages in combination. That makes it commercially attractive as well as more sustainable."

Playing field postal and parcel companies

The industry itself is complex. Providers and recipients have different interests, aspects that must come together in the operation. "Providers want quality, security and timeliness at low cost," says Van Willigen. "Recipients expect their package without damage and exactly at the right time. Preferably also without paying extra for receipt or return. That requires flexibility and transparency in costs. This often leads to a combination of systems that complement each other." Data is a second factor whose importance is growing rapidly, according to BEUMER. "Those who have better insight into processes can plan more efficiently and reduce costs. We often see companies investing in separate solutions, but then total handling costs still rise. By using data smartly, you can maximize the cubic meters in a facility and make entire operations more efficient," Van Willigen said.

From cost to value

When making investment decisions, he says companies still often look only at the purchase price. As a result, companies regularly opt for the use of AMRs, Autonomous Mobile Robots, which independently transport totes or pallets. "That seems cheaper, but per cubic meter and per handling the costs are sometimes actually higher. We like to enter the conversation to make that transparent. It often turns out that the right automation is less of a cost, but rather an opportunity to create value."

Invitation Parcel + Post Expo

At the Parcel + Post Expo in Amsterdam, BEUMER Group will present its solutions, including the Pouch System. Van Willigen: "Visitors there can experience for themselves how technology helps companies look ahead, work smarter and stay competitive. For us, this is the moment to engage with the industry.