Smart shuttles in the freezing cold

At 21 degrees below zero, there is no room for malfunctions. Yet Inther Group manages to run fully automated logistics processes under these extreme conditions. CEO Martijn Herder explains how the company's deep-freeze solutions—such as the shuttle concept—help meat processor Westfort to work faster, more energy-efficiently, and with higher product quality.

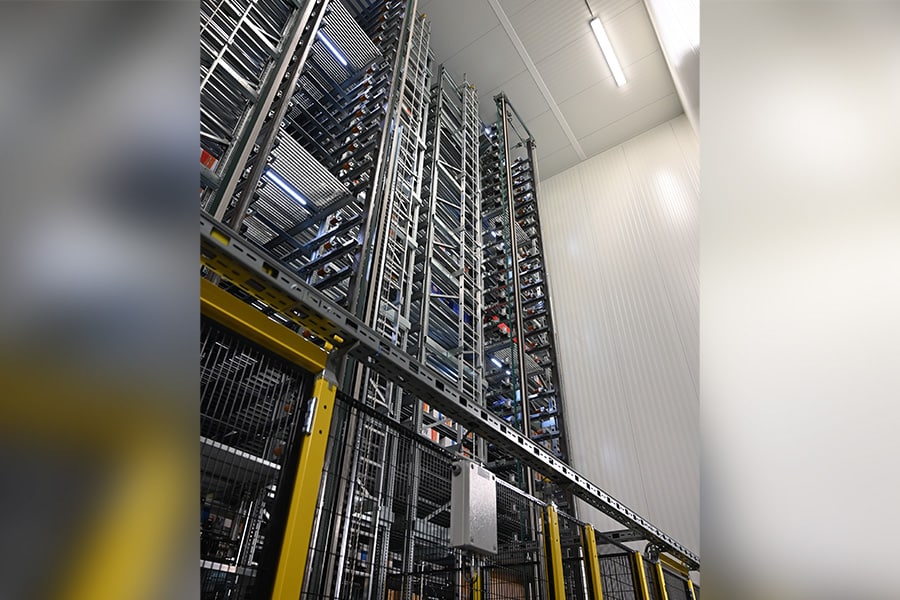

“Freezer space is expensive, so the more compact your storage, the better,” says Herder. Whereas traditional cold stores store pallets, Inther uses shuttles: small carts that store individual boxes at great heights, up to twenty meters high and three deep. This enables storage at box level – something that is technically very complex in a freezer environment. The advantage? Less space loss, more flexibility, and no manual handling in the cold. “People don't like working at minus 21 °C,” smiles Herder. “Our systems minimize human presence in the freezer room, and automation reduces the need for personnel as a whole—not unimportant in the current era of staff shortages.”

Westfort as an example

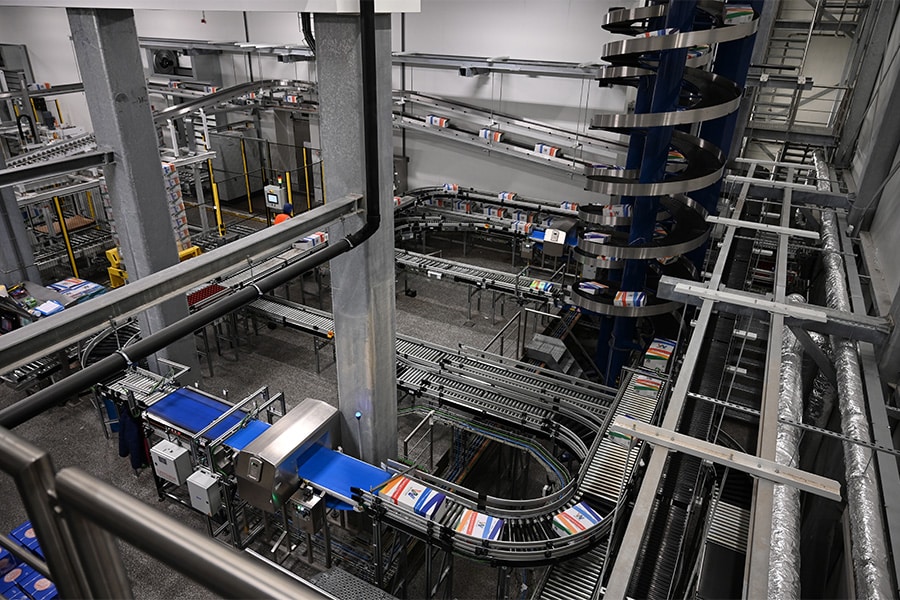

At Westfort Meat Products in IJsselstein, Inther's deep-freezing solution is being put into practice. The traditional method of freezing—first collecting in production, waiting until an entire pallet is full, transporting, and only then deep-freezing—has been replaced by a fully automated line.

As soon as a box of meat comes off the packaging line, it goes straight into a freezing tunnel. There, the product is frozen at lightning speed. The shuttle system then stores the boxes, sorts them automatically, and forms them into complete pallets.

“You no longer freeze pallets, but individual boxes,” explains Herder. “This saves up to 22% energy, prevents packaging deformation, and maintains higher meat quality. Moisture is retained, so weight is too—and that is literally worth money.”

Transportation also benefits: tight, non-collapsed boxes fill export containers more efficiently. “At Westfort, that saves an additional 8 % of loading space, especially when shipping to Asia,” says Herder.

Reliability below zero

In a freezing environment, reliability is crucial. “Moisture is the biggest enemy,” says Herder. “Our air is really dry. Ice buildup can cause beams to slide or parts to jam. That's why every component is specially engineered for these conditions.”

To stay ahead of malfunctions, Inther combines its maintenance experience with data analysis. Sensors monitor power consumption and even the sound of motors. “This allows us to identify deviations at an early stage,” explains Herder. “If a bearing starts to sound different, we can predict that it needs to be replaced. That's predictive maintenance in practice.”

Modular and scalable

The system can be used in existing frozen storage facilities, provided that the necessary structural provisions are in place. Herder: “Many customers start small and expand later. The concept has a modular design.”

Inther also advises customers on box sizes and material quality to ensure trouble-free operation. “A good box prevents operational problems,” says Herder.

From meat to pharmaceuticals

Although frozen food logistics may seem like a niche market, global demand is growing. “We are receiving requests from England, Germany, and Australia,” says Herder. “And the concept also works outside the meat industry. We apply the same shuttle and vision technology to pharmaceutical customers, in Hema distribution centers, and even at BMW.” Knowledge exchange between sectors accelerates innovation. “We learned a lot about traceability in pharma for food. And we are now using our experience with cold drives in refrigerated environments.”

Service and peace of mind

Because maintenance in frozen environments is specialized, Inther often provides resident engineers: its own employees who work full-time at the customer's site. “They know the system inside out,” says Herder. “This enables us to guarantee uptime of up to 99.99%.” Despite the pressure on the Dutch meat sector, Herder expects the technology to become widely adopted. “Whether it's meat, chicken, or fish, the need for efficient, reliable frozen logistics continues to grow worldwide.”