Modern WMS forms basis for logistics transformations

A modern Warehouse Management System (WMS) is essential in today's complex logistics landscape. Supply chain software provider Made4net, represented in the Benelux by Made4Logistics, sees that companies using advanced WMS solutions are best positioned to tackle four key logistics trends: omnichannel fulfillment, real-time inventory management, proactive inventory management and operational flexibility in volatile markets.

According to Jean David Benkimoun, Managing Director for Made4net's EMEA region, and Stephan Langedijk, Director at Made4Logistics, these trends are causing a fundamental shift in logistics operations: “Legacy systems simply cannot keep up. “Companies are reaching the limits of their operational and IT capabilities. Modern supply chain software has become the differentiator between those the companies that are doing well and those that are lagging behind.”

Global and local

With over eight hundred customers in thirty countries, Made4net provides supply chain execution and WMS software designed for global companies and local needs. The system also supports multiple languages and currencies. In the Benelux, Made4Logistics leads and supports implementations. “One of our best-known customers is the Ingka Group, with 390 IKEA stores in 32 countries,” says Langedijk.

Omnichannel fulfillment

Modern customers expect seamless shopping experiences across all components, including touch points at physical stores and online orders, click-and-collect services and mobile apps. This requires full synchronization of inventory and visibility across every sales channel, according to Made4net. It is no coincidence that Langedijk cites IKEA as an example. The Ingka Group is currently rolling out Made4net's WMS to strengthen its omnichannel capabilities. “Customers expect a reliable fulfillment experience wherever they store,” Langedijk says. “Made4net's WMS provides the real-time visibility and control needed to enable that consistency.”

Smarter inventory management

Real-time visibility is a necessity, not an option. At Rhima Netherlands, supplier of professional dishwashing systems, Made4net's WMS enables full serial number tracking throughout the life cycle of each machine. From receipt to installation, during maintenance and after-sales support. Says Benkimoun, “This allows them to immediately identify each customer's specific machine, even 20 years after installation. That kind of visibility has improved customer service and increased sales.”

Better process management, fewer errors

HSB Haaften, a supplier to the hospitality industry, uses WMS to replace manual processes that previously led to expired or misplaced inventory. The company now captures data with scanners, something that eliminates handwritten notes and prevents input errors. The system signals approaching expiration dates and verifies shelf life requirements, resulting in fewer picking errors, better process control and less waste.

Basis for innovation

A modern WMS lets companies explore new forms of automation, such as robots, drones and AI-assisted vision picking. “With these, companies can process orders faster, more accurately and more flexibly,” said Benkimoun and Langedijk. “With labor shortages across the industry, software that replaces manual tasks and improves accuracy offers a major competitive advantage. A modern WMS is no longer a system upgrade, it is a strategic necessity for resilience, efficiency and growth.”

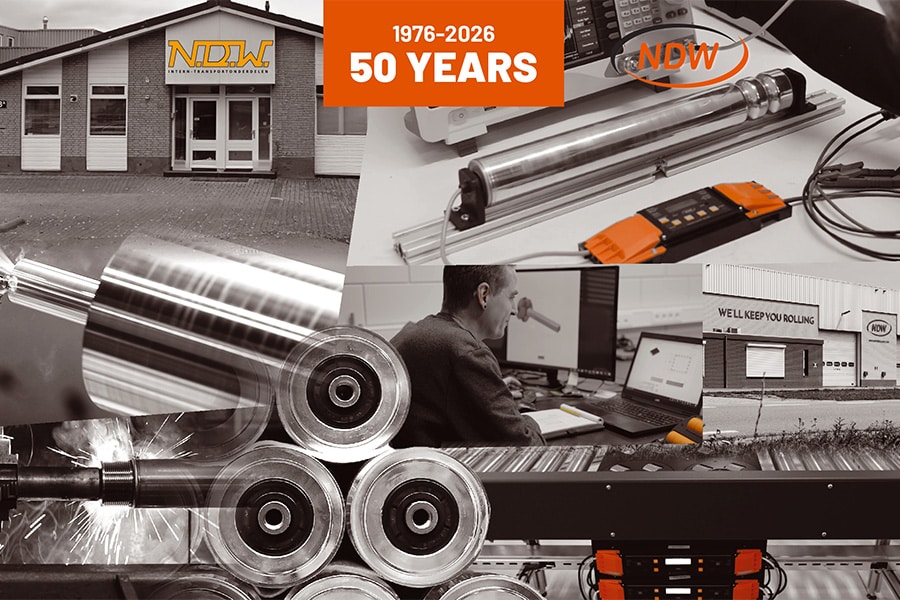

A modern WMS is a strategic necessity for resilience, efficiency and growth, states Made4net. (Image: Made4net)

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Made4net.

Contact opnemen

Contact opnemen