Distinctive floors deserve international attention

Van Berlo has been providing high-quality concrete floors for over 45 years, applying innovative technologies. The sustainable floors and smart innovations have resulted in numerous appealing projects. Currently, the company is working on a new chapter: expanding its international brand awareness and developing a leading role as a knowledge center for sustainable and high-end industrial floors. At the Transport & Logistics fair in Antwerp, they are presenting these ambitions together with their Greymatter technology, which achieves a significant CO2 reduction.

Senior sales engineer Daniël Toonen and commercial manager Tom Klaassen explain why precisely now is the time to roll out their expertise internationally. "Although we have always carried out projects abroad, we decided in 2024 to really make international growth a strategic spearhead. Indeed, although recognized and proven as the standard in the Netherlands and Belgium, jointless floors are still relatively unknown abroad. And that, while they offer great advantages. Think of flexibility in terms of rack layout, lower maintenance costs, improved hygiene and less wear and tear on equipment," Klaassen gives as examples.

Team Abroad

To achieve international expansion, a specialist team has been assembled of which Klaasen and Toonen are part. "The next project is a logistics floor of over 21,000 square meters in Denmark. What is special here is that we not only supply the floor, but also transport our pile drivers to produce the floor piles, the so-called Mini Vibro piles, ourselves. Because we carry out the entire project with our own people and resources, we guarantee flexibility, continuity and reliability," said Toonen.

Knowledge center concrete floors

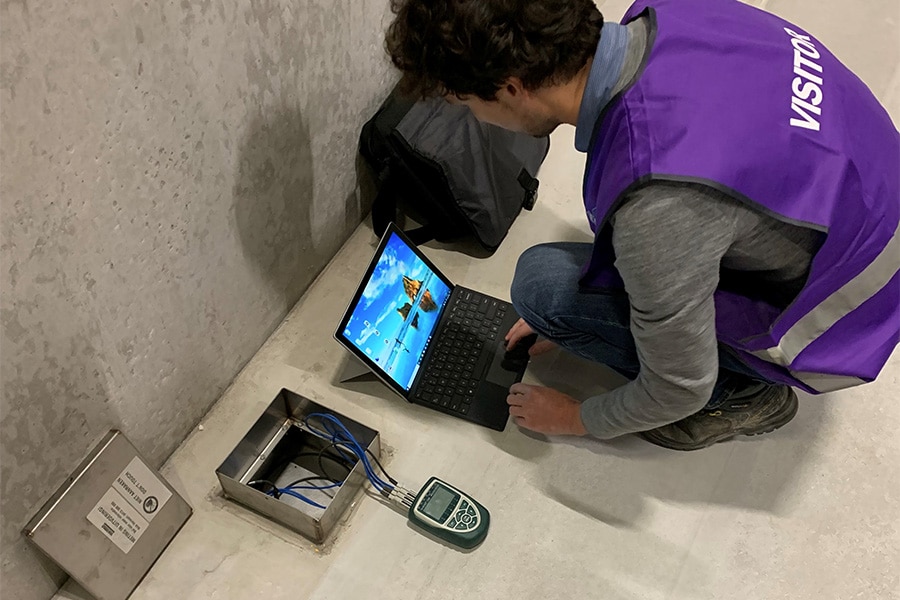

Van Berlo is currently developing an online knowledge base with white papers, webinars, customer stories and case studies. Toonen explains how they see their role as a knowledge partner: "Our goal is that everyone automatically sees Van Berlo as the first point of contact when it comes to a suitable floor. Because we have the knowledge and experience to offer a customized solution for every project. If Van Berlo doesn't know it, nobody knows it," he says with a smile. "Our customers often know how to find us with very specific questions. For example, how they can reduce settlement differences, increase bearing capacity or optimize service life. We then not only think along, but also provide specialist advice, focused on concrete solutions."

Klaassen adds: "In fact, we strive for the one-stop-shop concept: a central point of contact for everyone involved in logistics construction. This also prevents late thinking about the floor. We recently ran into a construction project where a company wanted to implement automated processes in the hall. Only a month and a half before the hall was to be fitted out, the question was asked whether the floor was actually suitable for this. A missed opportunity. If we had been involved from the beginning, it would have made a considerable difference in costs. After all, the robots and machines in an extremely automated environment can only perform optimally if the floor is flat, smooth and stable. This is where our floors really stand out. Flatness provides safety in addition to comfort."

Greymatter Technology

Van Berlo`s Greymatter technology enables concrete floors with greatly reduced CO2 emissions. Toonen: "We reduce emissions without making concessions on quality. Even better: the floor is of higher quality and more durable than traditional concrete floors, and, if desired, also free of shrinkage cracks. So thanks to this technology, one can easily make a huge hit on the sustainability score."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Van Berlo - smart concrete floors.

Contact opnemen

Contact opnemen