The secrets behind the success of 20 years of I-Shift

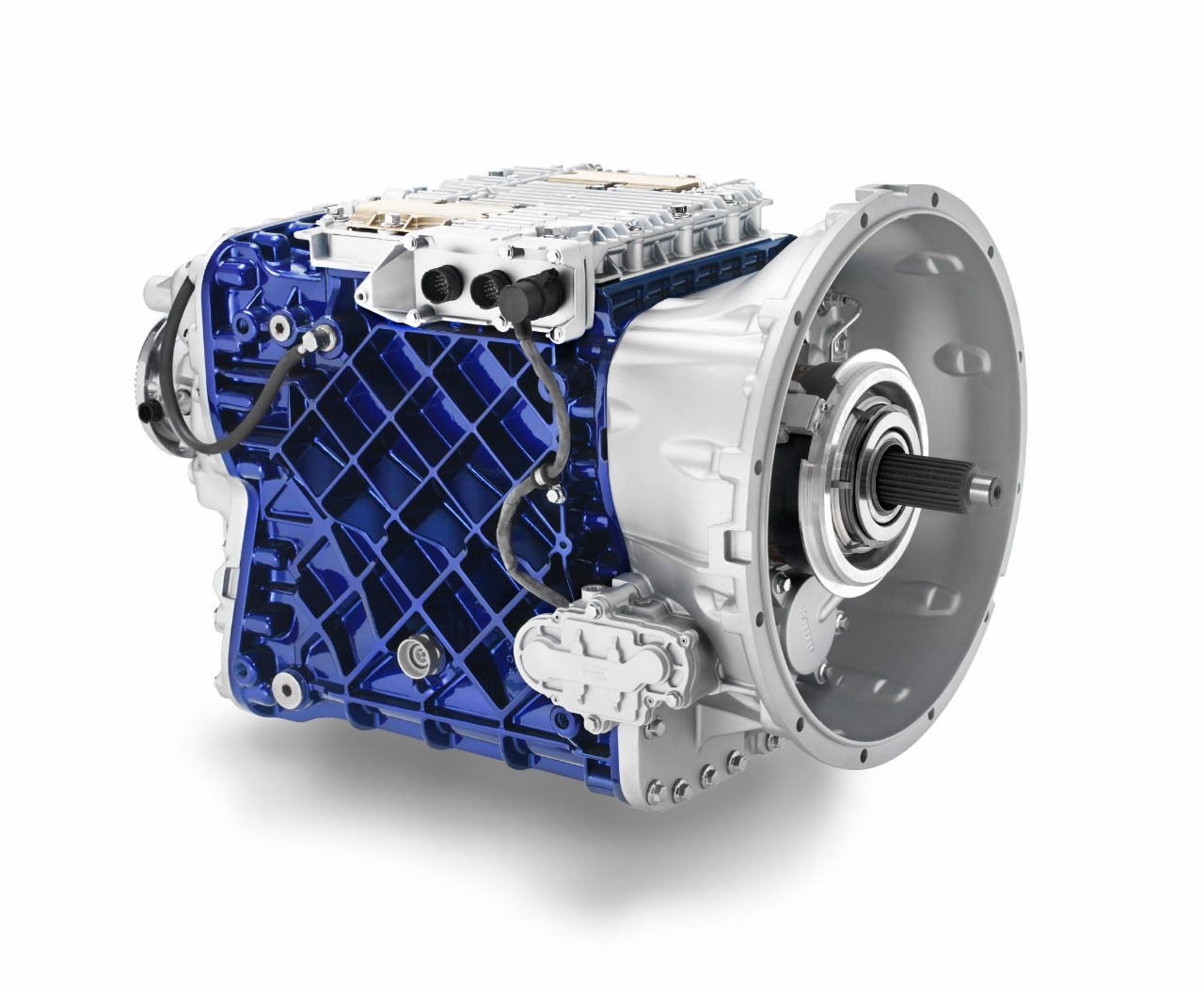

When I-Shift was introduced in 2001 as the first-ever automatic transmission for heavy-duty trucks, it was met with widespread skepticism in the industry. Some thought the automatic transmission would be a less reliable alternative to its manual counterpart.

Volvo Trucks, however, had complete confidence in a gearbox designed for automatic shifting, and this persistence paid off. Tests and customer experience quickly revealed the many invaluable benefits of I-Shift: not least of which were reduced fuel consumption, improved safety and reduced driver fatigue.It was a bold move, but it worked. A major breakthrough soon became a major success.

Pär Bergstrand, Heavy Duty Transmission Manager, Volvo Trucks Pär Bergstrand, Heavy Duty Transmission Manager, Volvo Trucks

Pär Bergstrand, Heavy Duty Transmission Manager, Volvo Trucks

"It was a bold move, but it worked. An important breakthrough quickly became a great success," says Pär Bergstrand, Heavy Duty Transmission Manager at Volvo Trucks.

Today, all Volvo FH and FM trucks are equipped with I-Shift as standard, and by the end of 2020, Volvo Trucks had sold more than one million I-Shifts around the world. Without a doubt, this system continues to set the standard for heavy-duty automatic shifting gearboxes worldwide.

Dual clutch, creep gears and changing driving direction

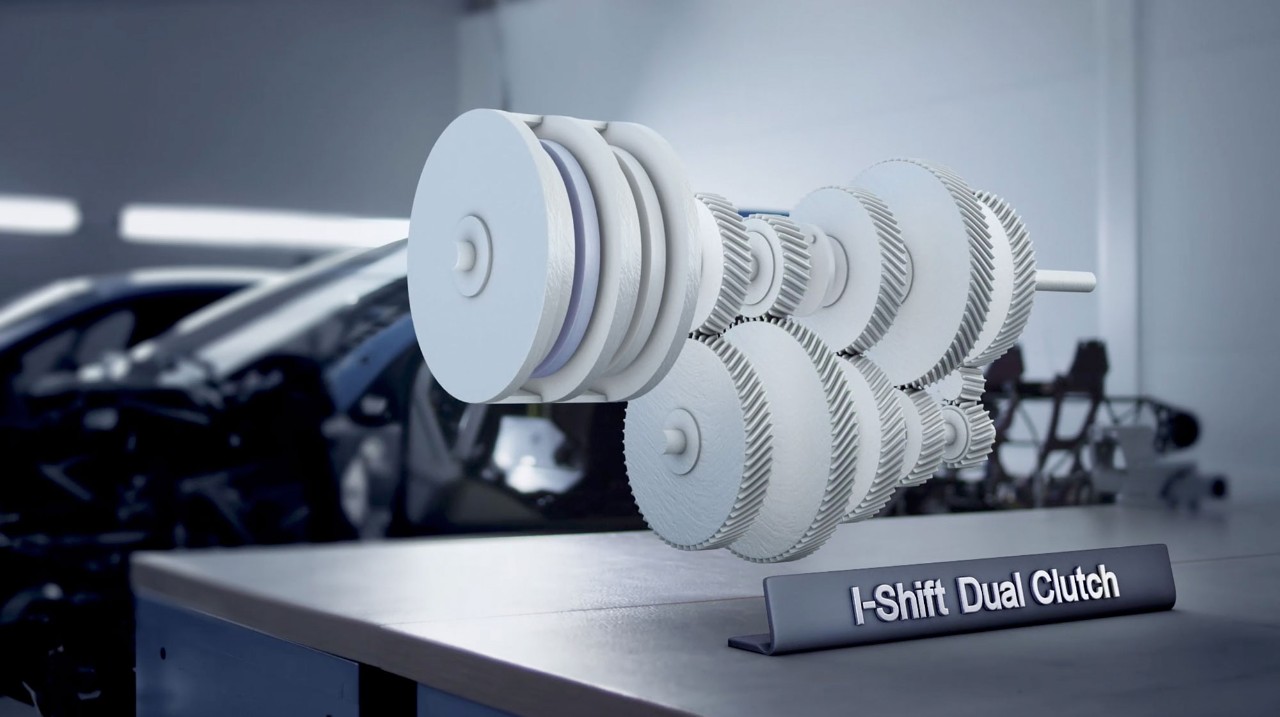

Since its introduction, I-Shift has been further developed and improved to meet the demands of an ever-increasing range of transportation applications. In 2014, Volvo Trucks released the I-Shift Dual Clutch out, another world first. This heavy-duty double clutch provides smooth, direct power delivery with no power loss during shifting. In fact, this enabled the truck to maintain a more stable and higher average speed. The innovative I-Shift Dual Clutch offers smooth power delivery without power loss during gear changes.

The innovative I-Shift Dual Clutch offers smooth power delivery without power loss during gear changes.

"I-Shift took a big step forward when we developed the Dual Clutch. Driving in environments that require a lot of shifting was suddenly much easier and more efficient. This led to a significant improvement in overall driving characteristics," says Niklas Öberg, Feature Leader Driveline at Volvo Trucks.

Progress did not stop there. In addition to ongoing software improvements, another important step was taken in the development of I-Shift. In response to customer feedback, it looked at heavy duty tasks where extra torque and starting power is demanded.  Niklas Öberg, Feature Leader Driveline, Volvo Trucks

Niklas Öberg, Feature Leader Driveline, Volvo Trucks

I-Shift with creep gears was introduced in 2016. It allows a truck with a load of up to 325 tons to drive away from a standstill on level ground (it has even achieved 750 tons as part of a record attempt with Sweden's strongest man: Magnus Samuelsson).  Sweden's strongest man Magnus Samuelson and I-Shift with creeper gears can handle 750 tons.

Sweden's strongest man Magnus Samuelson and I-Shift with creeper gears can handle 750 tons.

The gear ratios make the truck really crawl, with speeds as low as 0.5 km per hour. This is extremely useful when performing precision maneuvers, such as on construction sites or when hauling logs. The additional starting gears also require less rpm. As a result, fuel consumption and environmental impact are lower and less wear also occurs on the driveline.

In 2020, the New heavy duty range from Volvo Trucks introduced. This marked the beginning of yet another unique improvement: the new I-Shift Change Direction feature (available in AVO-ENH), which allows the truck to change direction of travel without the driver having to use the brake pedal. New heavy duty trucks from Volvo Trucks

New heavy duty trucks from Volvo Trucks

Niklas Öberg explains: "When the driver selects reverse gear and then accelerates, the truck automatically stops to change direction of travel. That means you can change gears in between. It works even at full throttle, because you can use the accelerator pedal to choose how fast you stop."

The Change Direction function is especially suitable for construction and mining operations, where it is more productive to perform repeated maneuvers for back and forth driving at relatively high speed.

"The idea actually came from Volvo Construction Equipment and VCE customers are very excited about it. It's a smooth, robust feature and I-Shift is the only gearbox that has this feature," says Pär Bergstrand.

The exchange of knowledge and feedback from customers within the Volvo Group is invaluable, especially when developing new ideas to improve existing technology, such as I-Shift.

A fuel-saving trio: I-Shift, I-See and I-Save

It is clear that the passion and perseverance of the people behind I-Shift have made this the success story it is today. But Pär Bergstrand also wants to emphasize that I-See, combined with I-Shift, plays an important role when it comes to fuel efficiency.I-See analyzes map data from the cloud about the topography of the route to be driven, and relays to I-Shift what needs to be done to save fuel.

Pär Bergstrand, Heavy Duty Transmissions Manager, Volvo Trucks

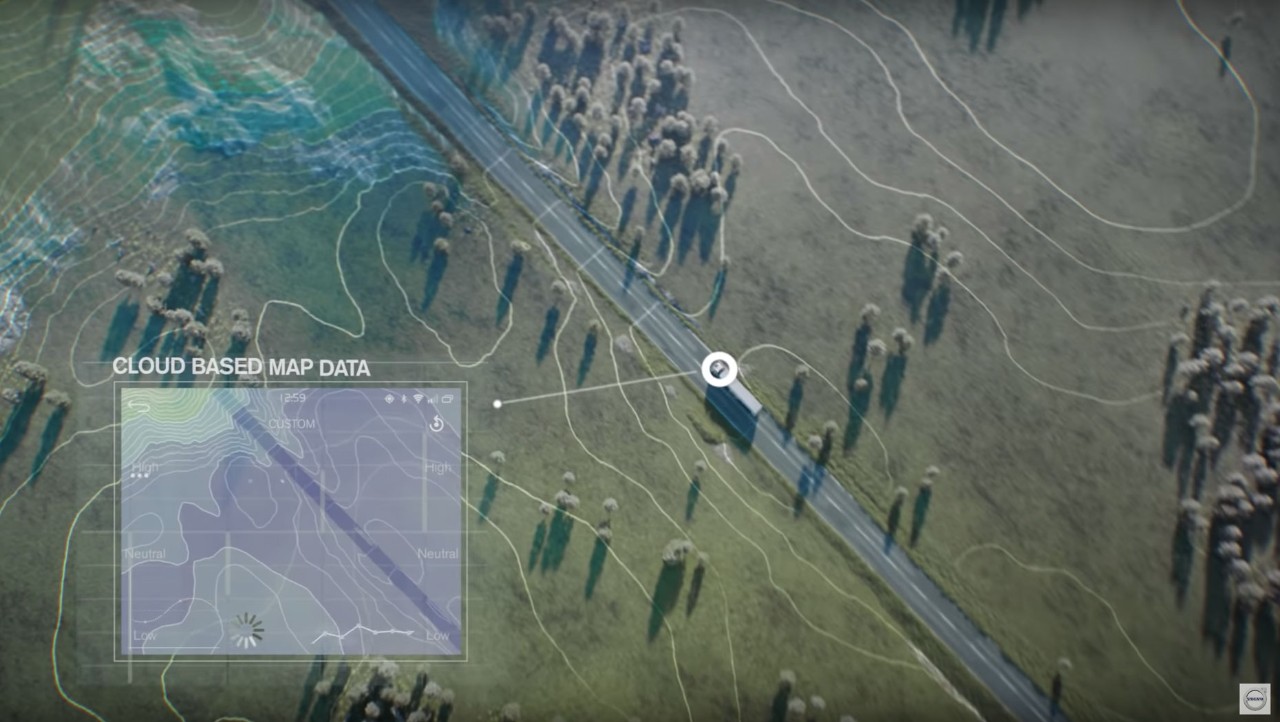

"I-See analyzes map data from the cloud about the topography of the route to be driven, and relays to I-Shift what needs to be done to save fuel," he says.

I-See is actually a unique combination of I-Shift with predictive (predictive) cruise control. Basically, I-See tells I-Shift the optimal time to shift gears on inclines and descents. This saves energy and thus fuel.  I-See analyzes map data from the cloud about the topography of the route to be driven.

I-See analyzes map data from the cloud about the topography of the route to be driven.

I-See can also collect data when cruise control is turned off and the driver sets the speed himself. Moreover, in the new truck range introduced in 2020, I-See can already be enabled at a minimum speed of 40 km/h. This ensures improved use of cruise control and maximum fuel savings.

The main advantage is undoubtedly that I-Shift can use I-See's knowledge to save fuel, and this works best when cruise control is engaged. The combination of the two technologies also allows the truck to maintain a constant average speed.

"It's all about driving the truck as well as possible so that the engine performs optimally. A combination of a constant average speed, low fuel consumption and driver comfort, then you have hit the sweet spot," says Niklas Öberg. I-Shift and I-See are an integral part of the I-Save package. The trio of technologies work together to reduce fuel consumption.

I-Shift and I-See are an integral part of the I-Save package. The trio of technologies work together to reduce fuel consumption.

The focus on saving fuel and reducing environmental impact also led to the development of the Volvo FH with I-Save, the most fuel-efficient Volvo truck for international transport to date. The key to I-Save's success is the D13TC engine with Turbo Compound technology. By reusing heat and energy, this results in a powerful but extremely fuel-efficient engine. Both I-Shift and I-See are an integral part of the I-Save package, and the trio of technologies work together for maximum fuel savings.

20 years later: a universal approach

So what is the secret behind the success of 20 years of I-Shift? The answer to this question, according to Niklas Öberg, is a combination of factors.The success of I-Shift lies in its ability to function in perfect harmony with I-See and the entire powertrain.

Niklas Öberg, Feature Leader Driveline, Volvo Trucks

"The success of I-Shift lies in its ability to function in perfect harmony with I-See and the entire powertrain. Over the years, the system has also been constantly improved to meet customer requirements, not only in terms of high performance and efficiency, but also when it comes to optimal driveability."

Pär Bergstrand adds, "Because we developed the system ourselves, I-Shift is fully synchronized with the rest of the truck. That's what makes it so unique and versatile. It is the result of 20 years of hard work, valuable testing with customers and their feedback, and the fact that Volvo Trucks has access to the technological edge of the entire Volvo Group." A fully self-propelled Volvo FH in action at the limestone quarry in Brønnøy, Norway

A fully self-propelled Volvo FH in action at the limestone quarry in Brønnøy, Norway

Looking ahead, I-Shift will inevitably be adapted for electric Volvo trucks and further improved for diesel trucks. As an automated technology, it will also be able to contribute to fully autonomous transport solutions, such as the commercial operation at Brønnøy Kalk AS in Norway. In addition to the many reasons for its success, it is the versatility of I-Shift and the innovative team behind it that keeps moving forward for the future challenges of the transportation industry.

The benefits of I-Shift

For the driver - excellent driving characteristics

- Helps improve performance

- Improves safety by allowing the driver to concentrate on traffic

- Reduced noise, vibration and physical strain

- Reduces fatigue

For the business - versatile and efficient

- Works in harmony with the entire Volvo Trucks powertrain, offering high performance, good handling and fuel economy without compromising average speed

- Optimized for fuel economy, especially when combined with I-See and fuel-saving software

- Reduces environmental impact

- Can be adapted to a wide range of transportation applications with options such as Dual Clutch for high performance and creep gears for heavy duty jobs

- Remote software updates enable continuous improvement in vehicle performance

- Guaranteed smooth shifting gives a more durable gearbox

In technical terms - some innovative highlights

- Compact, robust hardware with relatively few parts allows for easier maintenance and greater truck availability

- Dual clutch provides uninterrupted torque transfer during gear changes. Creep gears provide extra torque and excellent starting power in heavy duty jobs

- Change Direction function for changing driving direction (available in AVO-ENH) is ideal for changing driving direction quickly and efficiently, especially when performing repeated maneuvers

The I-Shift software

I-Shift functions have been optimized with specially tuned software packages for specific transport conditions, making the system even more practical and economical.

Four packages are available:

Long Haul (DRM-BE & AVO-BAS)

Standard package included with the truck. Contains basic functions for all-round driving.

Distribution & Construction (DRM-BE & AVO-ENH)

This package delivers more starting power and better maneuverability and the Change Direction feature to increase productivity when performing repetitive maneuvers.

Heavy Duty Transport (DRM-BE & AVO-HD)

Optimizes I-Shift for high train weights (85+ tons GCW). Heavy Duty mode can be turned on and off by the driver. Useful for trucks towing multiple trailers.

Fleet Specification (DRM-E).

A simplified package tailored to fleet managers.

Further options

All four packages can be combined with I-See for further fuel optimization. Additional software is available for the I-Shift and for the dashboard selector lever to further customize the truck.

Creep gears is a hardware option for the basic I-Shift. One or two forward creep gears and multiple reverse gears can be added (Multi Speed Reverse). All software packages can be combined with creep gears.Read more about I-Shift here