Why a data-centric approach is good

"Do you know Andrew Ng?", Lenze CEO Christian Wendler asks his guests upon arrival. "You should, absolutely." Wendler clearly has his eye on this man. And this man from Silicon Valley, the home of big data sets, has been talking publicly about smaller data sets for a while now. That made Wendler look up, because it's his story, too. The focus should be on data quality to harness the full potential of artificial intelligence, and Ng calls this approach data-centric AI.

Wendler interrupts the Google search: "Ng is one of the most important AI pioneers of our time, millions of people around the world have taken his courses - including many Lenze employees. The American founded Google Brain, taught at Stanford, and co-founded the world's most popular machine learning course on Coursera." In the past, the focus in artificial intelligence has been primarily on developing, improving and refining algorithms. Can Silicon Valley finally learn something from discrete manufacturing, from industries that have had to work with small data sets for years? Perhaps, but what is far more amazing is that companies in Silicon Valley are discovering the industry itself, and the many use cases on the factory floor. European companies welcome this, but new competitors are also entering the market - including industry-specific application expertise.

Just the right data

"Ng set up his own company specifically for this purpose," explained the CEO of German automation specialist Lenze. This has given him a wake-up call. The entrepreneur knows that less data is generated in industry and is usually unbalanced. Moreover, data in industry requires domain knowledge of the production process. This means companies need expertise in labeling the data. At the same time, engineers demand that their models be explainable.

Wendler is aware of the Americans' ambitions. Like Ng and his colleagues, he relies on a data-centric approach, with small data sets that are then turned into smart data. "In a big data approach, the user looks for correlations and patterns. An example is traffic planning. A machine or factory is a completely different application. Thanks to our process knowledge, I can specify search patterns to detect anomalies. I specifically extract only the 'right' data and evaluate it with my knowledge," Wendler summarizes.

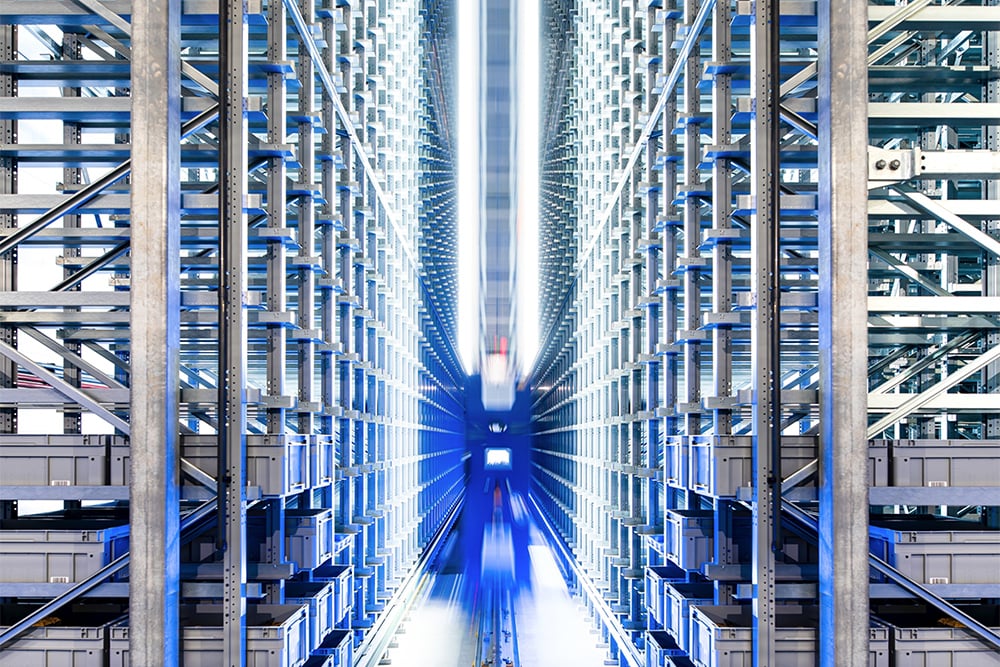

Digital twin as a data pool

He is proud of his team. His engineers rely on the digital twin. "The data from my machine flows into the digital twin - that's the data pool, so to speak. I fish out only the data I really need for my application. That's my little data. And with my domain knowledge, I transform my small data into smart data," Wendler adds. This is important to him: "We don't always need deep neural networks; we can also quickly identify what works how and where there is potential for optimization in the digital twin."

Saving huge amounts of energy

Together with their customers, the automation experts identified four smart data approaches. "When engineers in Germany plan a new machine, they play it safe. After all, German engineering has always been a hallmark of top quality and reliability. Even today, many engineers set excessive demands because they want to make sure the system performs well," Wendler reports. Experts call this the cascade buffer syndrome. It leads to unnecessary waste. "We can test the exact, performance design in the digital twin of the machines," Wendler enthuses. This saves energy, material, weight and transportation costs. The CEO calculates: "If we use the data in the twin and our smart data approach for even just 25% out of 50 million electric motors worldwide, or 12.5 million motors, we will save about 500 million euros in electricity costs per year and more than 2 billion euros in production costs." Wendler is now in his element. He picks up a brown packet. "We can save an enormous amount of energy in the e-commerce warehouse," he promises. Many conveyors run 20 hours a day at full capacity. "But we have to look closely at the usage data, and then it becomes clear: the customer only needs the maximum load for one hour a day."

CO2 emissions from 4 million cars

The electrical engineer does the math. "With the digital twin and thus intelligent, load-optimized motion control and efficient motors of the latest generation, I can achieve an impressive result. The energy consumption of a typical e-commerce facility with 800 motors, extrapolated to 13,000 parcel centers worldwide, saves 31 TWh. That is equivalent to the CO2 emissions of about four million middle-class cars. We assume that such an approach will enable energy savings of up to 50% for all production machinery and conveyor systems." He underscores the 50%. "These are values. We are using data to create real added value," Wendler says proudly. "The OEE hovers at 60% worldwide. We have calculated an improvement potential of 45 billion. Deloitte says the same thing."

Machine learning models

The premise: In 36 months, 82% of factory operators worldwide have at least one unplanned machine downtime, most have two or more. Many systems are still maintained on the "run-to-fail" principle, meaning that machine parts are not replaced until something breaks. And on average, production systems at each manufacturer lie idle for 800 hours a year. Auto manufacturers estimate lost sales at about 20,000 euros per minute of downtime. "And this is where we come into play, with our machine learning models. Thanks to predictive maintenance, trained on a small data set, I know when my timing belt will break and the customer can order and replace the part in a timely manner."

Skills in house

But does he have all the skills? Ng and his colleagues do nothing but train AI models. "Yes, we have those too, and they also know the customer's plant and work with the plant's digital twin. We exchange models, can quickly adapt them to other customer systems and save money, time, energy and resources." And Ng? He would love to meet him and show him Lenze's Mechatronics Competence Campus. Wendler jokes that his team can gain domain knowledge there. "The invitation has already been sent."