The warehouse execution system as the foundation for the dark warehouse

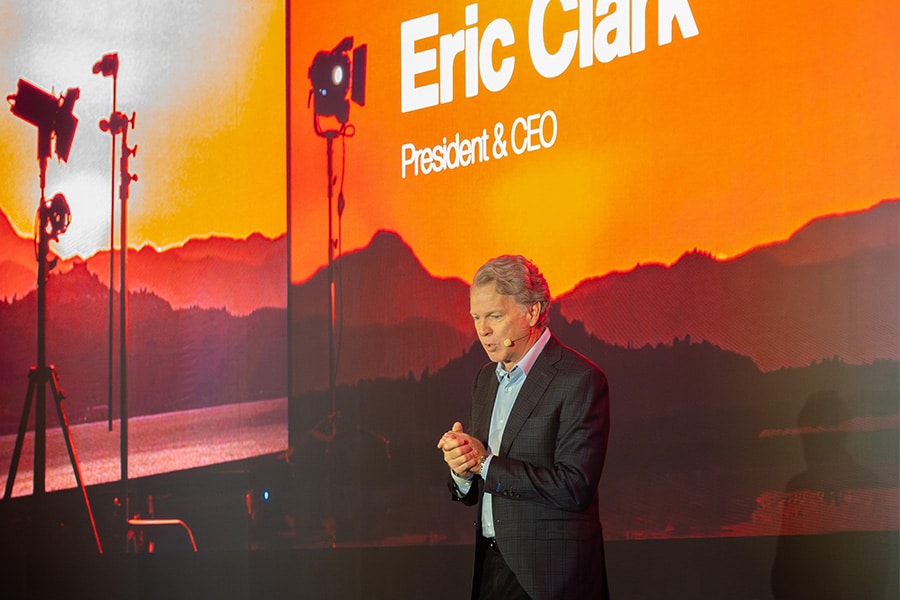

The pace of innovation for warehouses is faster than ever. New robotic solutions are bringing the future image of a dark warehouse ever closer. But those who choose to do so cannot escape a smart system that allows people, machines and robots to work together perfectly. Marco Klaassen, senior director of professional services at Manhattan, explains what a warehouse execution system does and why it is the foundation for automation and robotization.

The development of storage and order picking systems has gained momentum and the end is far from in sight. The cause, according to Klaassen, must be sought in the fact that warehouses have to speed up their processes: on the one hand because customers expect short delivery times, and on the other hand because of labor shortages. “The demand for robots is therefore increasing and they are becoming more intelligent and advanced,” Klaassen says.

Dark warehouse

In conversations with the most progressive customers, Klaassen increasingly hears the term dark warehouse. “That's a warehouse where the lights don't have to be on because all the processes are automated. Whether that happens with the mobile and climbing robots or with humanoid robots that take over the last remaining manual tasks from people. Such a dark warehouse is the future vision they have in mind and all the decisions they make today are aimed at realizing this future vision.”

One thing is certain: if the dark warehouse ever becomes a reality, it will consist of a mix of different systems. After all, not everything will fit into a plastic container measuring sixty by forty centimeters. “Since such a dark warehouse can never be realized overnight, a combination of automated and manual processes will be seen on the way to the final situation. That requires a solution that allows all these processes and systems to work together as one smooth machine.”

Warehouse-execution system

To that end, Manhattan provides a warehouse management system (WMS) with a built-in warehouse execution system (WES). All robots, shuttles, sorters and conveyors, regardless of supplier, are linked to the WES. This software system is in constant contact with all systems, keeps track of what is in stock in each system and knows its real-time status. As a result, it is able to optimally distribute the tasks coming from the WMS, keeping in mind the tasks that need to be performed manually. Because all flows and movements are closely coordinated, each order can be handled quickly, efficiently and without errors.

The WES makes the most of the available systems, people and supplies to streamline the overall operation, Klaassen argues. “The WES must be able to release orders dynamically, based on the status of people and machines. If a system reaches its maximum capacity, the WES must be able to adjust the division of labor and deploy additional people, for example. It is crucial to have an integral overview of the warehouse, considering manual areas as intelligent buffers.”

Developing strategy

What is the advice for warehouses not yet ready for automation? “When selecting and implementing a WMS, keep in mind that in the future you will automate. And that you will then need a system that can direct the entire operation,” says Klaassen, who calls on companies to develop a strategy. “A strategy that can serve as a guide when making future decisions about the deployment of robots or other automation solutions.”

Klaassen offers one final tip for organizations that do not have the knowledge in-house: “Then find a partner who can help make the right choices. As I said, it is uncertain whether a dark warehouse will ever see the light of day. But we are moving more and more in that direction. That also applies to smaller warehouses. Therefore, make sure you are prepared for that.”