‘RFID adds security to existing logistics and manufacturing processes’

Having more certainty about the location of loose items, boxes and pallets is worth its weight in gold. “Fewer errors and greater efficiency are the result,” states Egon Guilliams, business development manager at Turck Vilant, part of Turck. “RFID can be a very smart addition to existing processes. It makes stock movements less dependent on actions by operators.”

As a technology, RFID has been around for decades, but as it matures, its benefits to businesses are also increasing dramatically. Guilliams: “Entrepreneurs see it as a good addition to existing processes, increasing the security of goods flows.” RFID is easy to make part of a total logistics solution, as Turck also offers with pick-to-light racking and roller conveyor automation, for example.

‘Forklifts are smarter thanks to RFID’

A smart load carrier like RFID has two distinct advantages, according to Guilliams. “You make forklifts smarter by adding RFID. Logistics processes are then less dependent on the actions operators perform. If you add RFID to scanning processes, then you can be sure that the right pallets arrive at a customer.” He sees many companies still putting products somewhere and manually checking whether something is correct. “Assumptions, or a barcode scan, plays too big a role in that.”

Reduction of errors

The ‘error rate’ in many warehousing processes can be higher than desired. “An error always results in additional operations and costs. Sometimes an error also results in a huge cost or worse.” With the latter, Guilliams is referring to companies where a forklift operator finishes a recipe for production using materials from a warehouse. “The consequences are drastic if the driver picks up or delivers the wrong materials. The production process goes haywire and you create a waste product,” the business development manager states.

Additional verification

The move to using the technology often goes hand in hand with process improvements. “At Turck Vilant, companies knock on the door that see that logistics processes need an improvement, but don't know how to achieve it.” An on-site check frequently involves ingrained processes, according to Guilliams. “Usually it is not necessary to completely overthrow those processes and an additional checking function, such as with RFID, suffices. A forklift driver can remain seated instead of manually scanning goods.”

Multiple benefits

The greatest value RFID adds to logistics and production environments is reducing the probability of error, Guilliams says. “Additionally, loading processes, for example, can be optimized and made faster. That in turn has the effect that a warehouse operation can do with fewer loading gates. And fewer errors obviously lead to less aftercare in the chain and a reduced carbon footprint.”

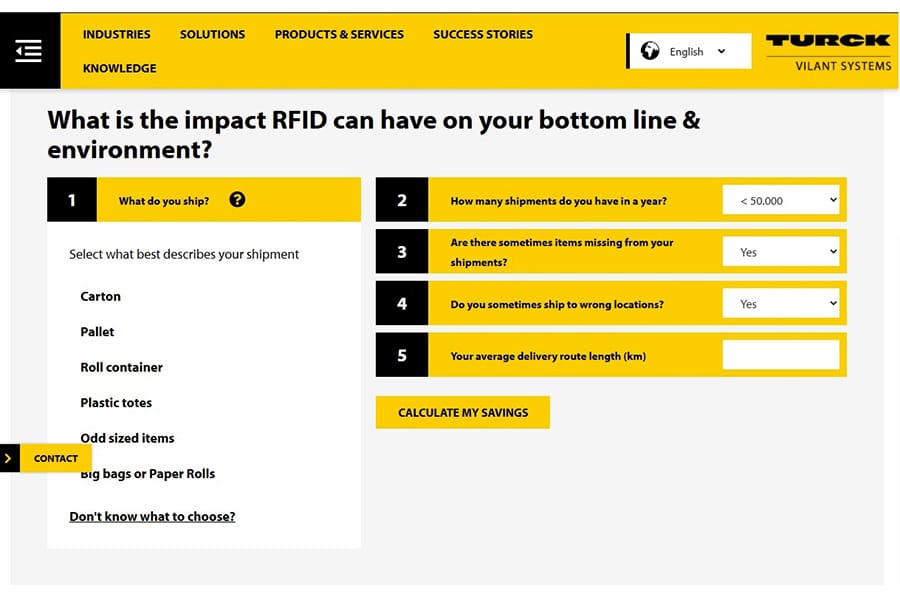

Shipment calculator tool

Turck Vilant has a free tool available that provides insight into the impact of using RFID and eliminating errors within the shipping process. The shipment calculator tool provides a quick and realistic estimate of cost savings and the positive environmental impact.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met TURCK MULTIPROX.

Contact opnemen

Contact opnemen