Lean management clearly points to a largely scan-free future

The days of forklift drivers driving through the warehouse armed with a scanner are coming to an end. Erroneous scans, lost pallets and inefficient trips are costing companies time and money. Moreover, reliable real-time data is essential now that algorithms and AI solutions are gaining ground at lightning speed. After all, AI can only function if it is fed data that is one hundred percent accurate. We spoke to Martin Welp, ceo of IdentPro. They were the first to market the technology for a scan-free system.

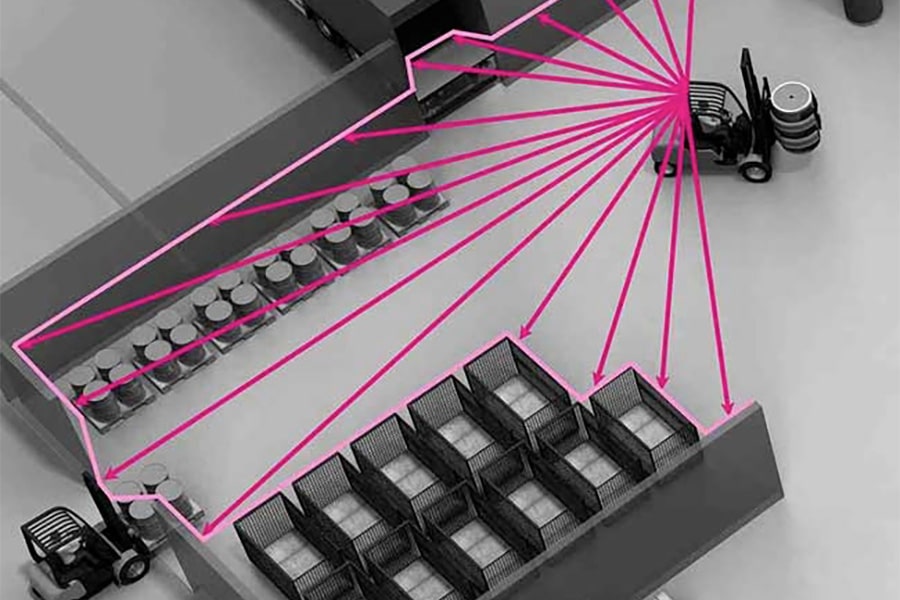

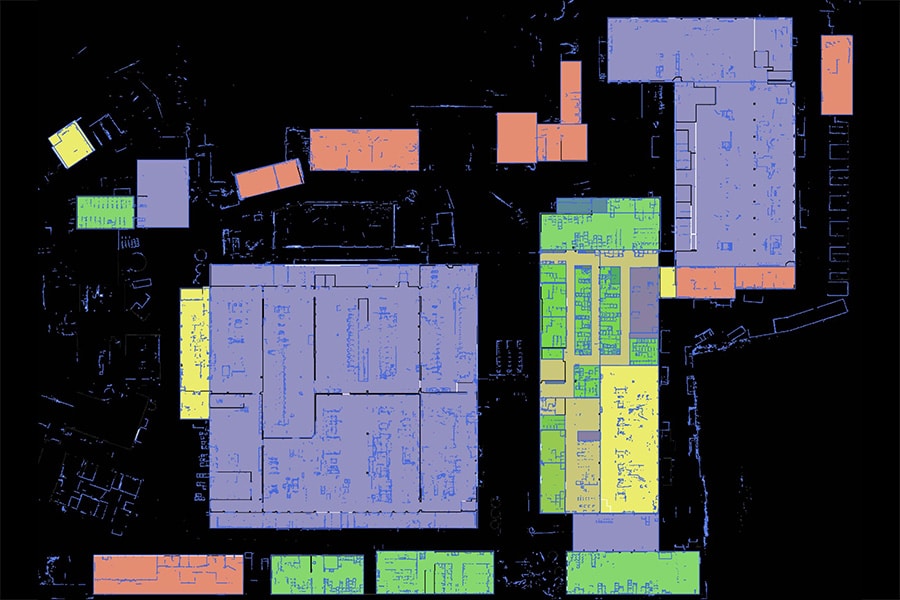

Developments within lean management clearly point to a largely scan-free future. To truly deploy AI in intralogistics, the hand scanner must give way to advanced solutions. Laser localization (RTLS) and real-time tracking allow AI to take charge. RTLS links goods information to geodata and automatically records goods movements via sensors mounted on material handling equipment. This provides solutions to bottlenecks in warehouses and lays the foundation for automatic data processing in line with lean management principles.

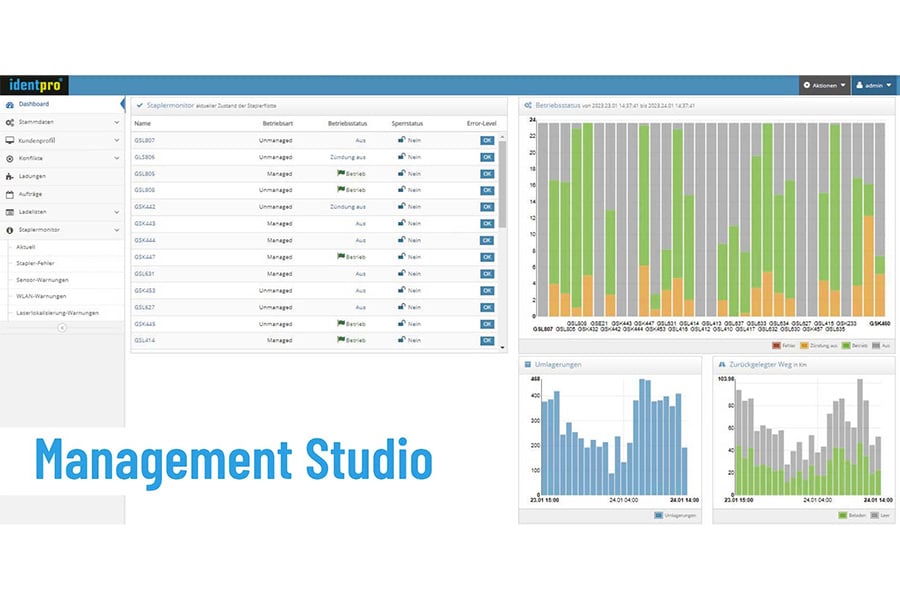

IdentPro delivers a unique warehouse execution system (WES) that, thanks to sensor technology on forklifts, gives real-time insight into all goods movements. This sensor technology is so different from existing solutions that large companies such as Warsteiner and Thyssen Krupp have already implemented the system. Compared to other WES solutions via RFID, UWB or camera, IdentPro is distinguished by the centimeter- and millisecond-accurate creation of the Digital Twin. “For many, our solution is still new,” Welp says, “but it is proven, reliable and ready to take intralogistics to the next level.”

Carefree transition

That companies need not be reluctant to implement it is proven by companies such as A+C Plastics and Bürstadt Furniture. Reputable companies such as ELA Container and Schütz are now even rolling out the technology across multiple sites. “The fact that such parties opt for wide application after an initial experience says it all. Implementation takes only one to three months and the changeover is intuitive and worry-free. Apart from project management and installing sensors on vehicles, no major modifications are required. Once the software is interfaced, real-time tracking can begin immediately.”

Favorable ROI

“Our system provides data from day one on things like empty runs and idling vehicles,” Welp explains. “This allows companies to quickly determine, for example, whether they can get by with fewer forklifts. With an ROI of less than a year to a maximum of two years, depending on the initial situation, the return on investment is remarkably quick.”

Good time

When asked why now is a good time to switch, Welp replied, “Companies are dealing with a generational difference. Whereas current employees often have years of experience with their processes, the new generation does not want to enter into a long-term working relationship with one employer. As a result, knowledge and experience quickly disappear from the company. A second reason is that reliable real-time data is essential now that algorithms and AI solutions are gaining ground at lightning speed. And manual scanning remains error-prone. Finally, a move to a scan-free solution has only recently become possible. Ten years ago, the technology did not exist. We were the first to bring this solution to the market. Since then, up to two companies have joined us that also offer this technology, but they have much less experience.”

Future-proof

Anyone who wants to know more and is visiting the ICT & Logistics fair in Utrecht in November should definitely visit IdentPro's booth. Welp concludes: “The message I want to convey is that reliable real-time data is the key. With it you can make processes more efficient today and lay the foundation for the next step: AI-driven intralogistics. This does not depend on economic constraints, labor shortages or the skills of your personnel. Digitalization enables companies to secure the future.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met IdentPro GmbH.

Contact opnemen

Contact opnemen