Lingerie brand offers warehouse workers safe workplace

With a new distribution center in Almere, Hunkemöller has all the space it needs to realize its ambitious growth plans. The move to this building has not only increased efficiency, but due to the increase with automation it also brings greater safety risks. With Flexbarrier's collision protection, the lingerie brand has been able to minimize the risk of damage and accidents for internal traffic and pedestrians. Health & Safety officer Lisanne Gottmer-Zeldenrijk: "All employees can now walk to their workstations safely."

Since the fall of 2024, Hunkemöller's stores will receive their products from Almere. There, the lingerie manufacturer has built a modern distribution center of over 19,000 square meters. Every day about 150 employees - rising to 250 in the high season - are busy processing the orders from more than 900 stores from 19 countries. In doing so, they receive help from two automation systems: a large part of the stock is held in a mini-load system with six cranes, while a robotic system has been installed on one of the mezzanines. That system has one hundred robots constantly moving to bring the mobile racks of picking stock to the order pickers.

Safe to the workplace

The move to Almere represented a big step for the employees. For decades, Hunkemöller operated from a warehouse in the middle of Hilversum, which had become too small. "The safety risk was a lot lower there because we did everything manually. The order pickers went on foot with their carts along the shelf racks. For internal transport, we only used hand pallet trucks. The only mechanization consisted of a single roller conveyor," says Gottmer-Zeldenrijk. "Now all of a sudden we are working in a large distribution center with reach trucks and electric pallet trucks, where collision protection and a traffic plan are needed to manage the transport."

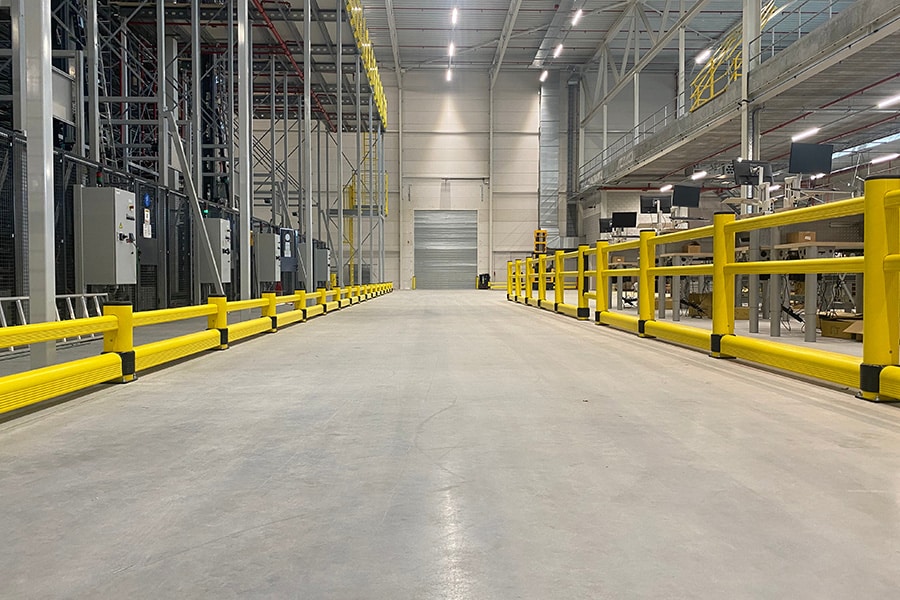

A busy distribution center requires good collision protection to protect employees and prevent damage. "In such a large hall, we have to make sure that all employees can safely walk to their workplace and work there. That is why we have installed driveways and walkways on the floor, which we have separated as much as possible with a pedestrian barrier. Where that was not possible, the agreement applies that pedestrians always have priority over moving equipment."

Protection of ankles

The pedestrian barrier consists of a fence with rails at hip and knee height. "With an additional rail at floor level that protects employees' ankles from the scoops of the moving equipment. After all, employees are trained with the instruction to keep the scoops low while driving," says Gottmer-Zeldenrijk. "Employees should always walk behind the barrier. At the entrance, we have therefore fenced off an extra-large section of the floor so that employees are also safely behind the fence during day starts and toolbox meetings."

To prevent damage to the building's columns, Hunkemöller shielded part of them with a HUG TOWER. "In places where the very highest protection is needed for the building and equipment, we installed sturdy fencing so that reach trucks and electric pallet trucks cannot get close. In addition, we protected the mezzanine, freight elevator, sorting plant and other crucial installations. We also added additional collision protection to the fence around the mini-load system so that the cranes are not at risk."

Flexible arrangement

All collision protection, lineation and floor stickers were supplied and applied or installed by Flexbarrier. This supplier was preferred by Hunkemöller after a comparison. "We wrote to several parties and finally asked two suppliers for quotations. We compared them not only on price, but also on quality and durability. What also played a role was the short delivery time. Flexbarrier has been flexible in all respects and has constantly thought along with us. The cooperation with contractor Burgland Bouw and architectural and engineering firm Sweco was excellent."

The collision protection itself is also extremely flexible because of its modular design. "We built this distribution center with the future in mind. If we want to change the layout and processes, we can dismantle Flexbarrier's products and reinstall them elsewhere. Possibly with another post in it or an extra fence in between. This is very important to us, because Hunkemöller keeps moving. Also in this distribution center."

Customization at high speed

Visitors to hot distribution center were also surprised by the collision protection. During the inspection of the electrical installations, for example, an inspector objected because the switch boxes of the mini-load system could not be opened. This was because collision protection had been installed right in front of the cabinets. "We then showed that loosening a bolt with an Allen key is sufficient to loosen the guardrail and slide it off the base plate. With this solution, the switch boxes are well protected, but we can still open them quickly if needed. We use the same solution to give service engineers access to the mini-load system."

The assembly of all the collision protection went smoothly. Occasionally the mechanics encountered an unexpected problem, for example when they could not drill deep enough to anchor a column protector in the floor. Thanks to the creativity and flexibility of the assembly crew, they managed to solve these problems without compromising on workplace safety. "It was a relief that we didn't have to think about that ourselves," says Dr. K. K., who is a member of the team.

Blow absorbed

That the collision protection works has now been experienced by Hunkemöller. "The work in a distribution center like this remains human work," explains Gottmer-Zeldenrijk. "The crash protection has shown to work as promised: after a minor collision with a HUG TOWER, neither the floor nor the vehicle had any damage. Only the crash protection itself showed some marks. It absorbed the impact and thus did exactly what it was supposed to do."