Warehousing from 0 to 100

For the first time, Warehouse & Logistics is bringing together a panel of experts to take a look at the major challenges and evolutions facing the warehousing segment today. In the inspiring setting of Logiville, four professionals give their vision on the future of logistics in Belgium and the Netherlands.

We can kick off the panel discussion with a positive sentiment. Contrary to the general tenor of reporting on the economic climate, our panelists see full order books ahead.

"2025 has been a particularly good year so far and also a year of recovery. In 2023 and '24 the market made a standstill after a huge spike at the time of corona. 2025 is a good year in execution and in requests for new projects," believes Martijn Herder, Inther's CEO. "Logistics is simply a growth market. Even with a dip, the long-term prognosis is good. With the caveat that it depends very much on the region. In the U.S., some projects are on hold due to the uncertainty surrounding the Trump administration's import tariffs."

Thomas Monnens, ceo at Derdaele, shares that vision. Construction is again in full swing, it appears: "We are seeing extreme growth in applications for new construction. The portfolio is completely full. In previous years things were a bit slower, on the one hand because of the correction after corona, and on the other hand because of the time that is simply needed to get the necessary permits."

Warehouse equipment:

Nevertheless, logistics companies are now also looking more frequently at increasing efficiency in their existing buildings. This should come as no surprise: virgin industrial land has become scarce in both the Netherlands and Belgium.

"The number of projects in existing buildings is increasing," acknowledges Martijn Herder. "Companies can't find land for new construction, or, certainly in the Netherlands, don't get permits. Then you have to bet more efficient use of your current infrastructure. Even if new construction would be cheaper than such a major renovation."

Where new construction is still being opted for, the structures do look different from a few years ago. "The standard height has increased to 13 to 15 meters, compared to 6 to 7 before," says Thomas Monnens. "High-rise buildings have become the new normal. We obviously do this to make the best use of the scarce surface area, although this approach also has limits: the reach trucks still have to get the loads down safely. You have to sacrifice part of your land to build wadis. You have to make up for that loss on the remaining acreage."

In the Netherlands, the issue of grid congestion is also currently in play. "I saw a company that installed gas generators to have sufficient power," says Martijn Herder. "A sufficiently heavy electricity connection was not possible because of overcrowding on the grid, but a gas connection was possible. Look, entrepreneurs are resourceful in looking for solutions, but surely this goes completely against the goal of a greener energy policy? Customers now ask much more about the power consumption of the installation. You never used to get that question."

Ecosystem

A warehouse is pre-eminently an ecosystem where different business processes come together. For many (production) companies, logistics is not their core business: this creates extra headaches for logistics and it should not cost too much. On top of that, regulations and customer expectations can quickly change significantly. A little more coordination of all these interests would be useful, Thomas Monnens believes. "I would like to set up construction teams where all project partners are involved from the beginning: construction companies, designers, warehouse equipment, automation, so that we can make appropriate plans based on their input." Today, you only see that integrated approach in the very largest projects.

What challenges this brings, they know better than anyone at Begra. Key account manager Peter Dielissen testifies: "Customers want as much storage as possible in as little space as possible, with the complication that warehouse design is often a closing item: the building is there, and now shelving still has to be installed. Quick delivery is then the message. As a warehouse furnisher, you would prefer to step into the process a little earlier, so that you can come up with more customized solutions. You often have to implement solutions in environments that need to keep running. That requires ingenuity. In an SME where everything still smells like fresh concrete and you are given carte blanche, this is less of a problem. Often a bit of education is needed: familiarize customers with the various options. With some larger companies, this immediately involves complex systems; with a start-up, you start with racks and trays. These are often at the beginning of an evolution that as a supplier you want to be present from the beginning."

Automation between man and machine

Automation in the warehouse is a topic that has occupied the sector for years. Yet it is striking that today we are presented with less fully automated installations, but rather pragmatic setups in which man and machine work together optimally. The fully automated warehouse where no human hand is involved has not become the norm, although this seemed to be the expectation a few years ago.

Martijn Herder sees it this way: "Such a warehouse with no humans involved is probably a utopia. In the fine work of order picking and picking, the complexity is so great that full automation becomes difficult and expensive. When we install goods-to-man picking systems, we are always asked if they can eventually be robotized. However, it's so complex that it often doesn't pay off. It pays more for you to reduce the number of walk meters in the warehouse and use employees as efficiently as possible."

Cold feet

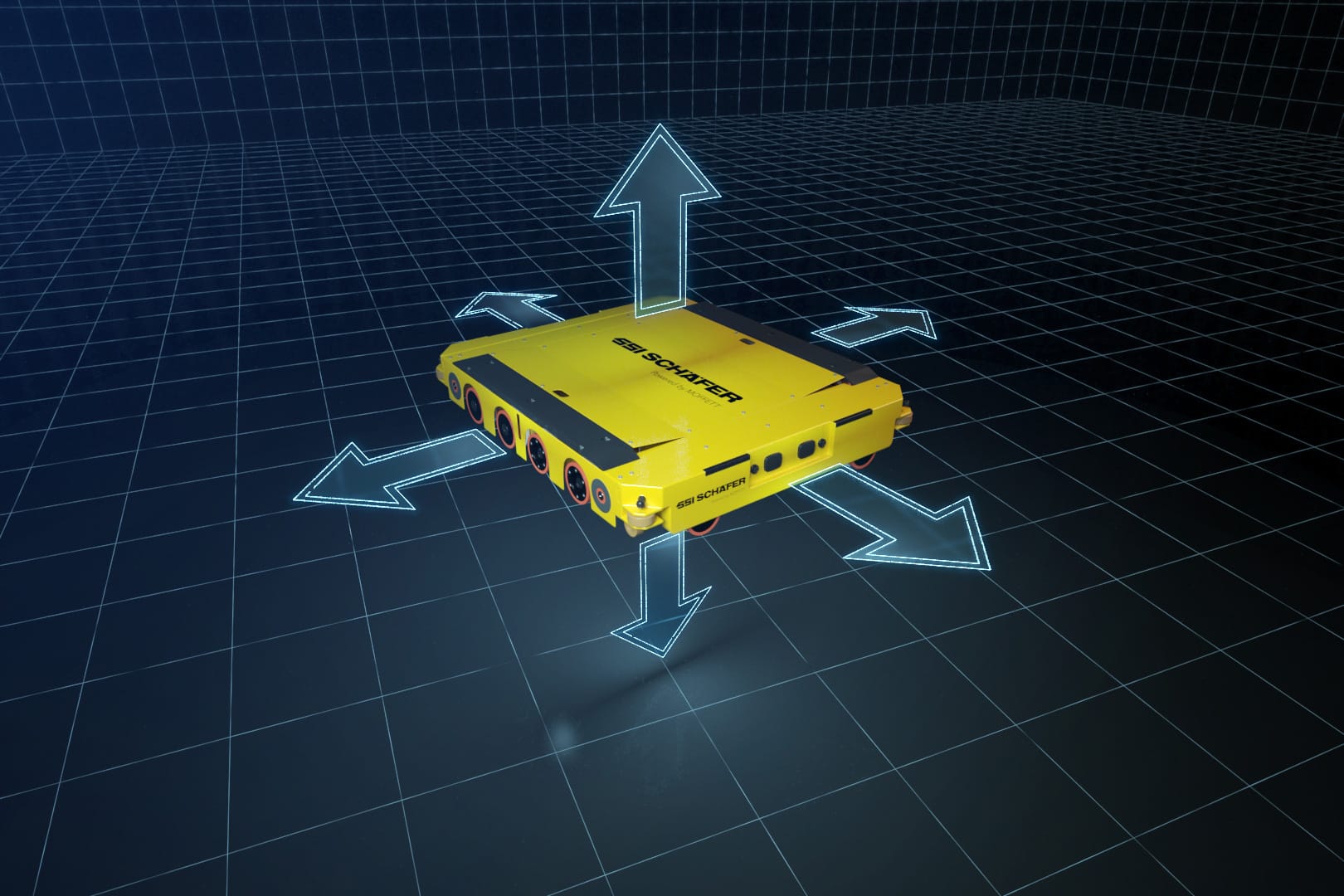

Martin Vonk of Motrac sees the demand for autonomous vehicles increasing, but makes a comment. "With some entrepreneurs there is still cold feet around automation, although the need for some automation has come through. The demand for AGVs, for example, is high, but you have to think carefully about how to deploy them. What flow of goods do you want to automate? It's best to start with a few clearly defined projects, such as reducing walking meters. You can always expand afterwards. Thinking along with the customer with an eye to the future is most important."

According to Martijn Herder, many customers do come knocking on Inther's door with clear intentions around automation. "They want to achieve growth with the current workforce; less dependence on employees (illness and turnover); reliability and availability of the installation; peak capacity.Your organization must also be able to cope with that change. This means that the entire organization, from management to the people on the floor, must be part of that story. Because it affects everything. We also do check whether the customer is able to keep the warehouse running with our solution and whether additional training is needed."

Magic word AI

Meanwhile, expectations around Artificial Intelligence (AI) are high, although it is not yet very clear where this technology will make a difference. According to the panel, we will still see AI at work fastest in the administrative part of logistics, in improving security systems and making WMS "smarter."

Peter Dielissen remains level-headed: "On the shop floor, the next step is still a long way off, it seems to me. Pallets have to be physically stored in a rack, AI cannot help with that. But it can in designing such a solution."

One stop shop?

More than ever, customers seem to be looking for an us stop shop for their logistics challenges. Sliced bread for classic integrators, of course, and it's no coincidence that classic suppliers of (intra)logistics equipment are increasingly raising their profile in warehouse design and WMS solutions.

Martijn Herder: "Customers ask themselves to what extent it is their core business to keep a logistics system running. They want to outsource, so logistics creates a kind of de-care issue that then comes to players like us."

Challenges enough, but our panelists look to the future with confidence. "We should be proud of the logistics activity in this region," concludes Martijn Herder. "People complain about the big black boxes in the landscape, but high-tech processes take place within them."