Increase your productivity with the new Volvo EC250E and EC300E excavators

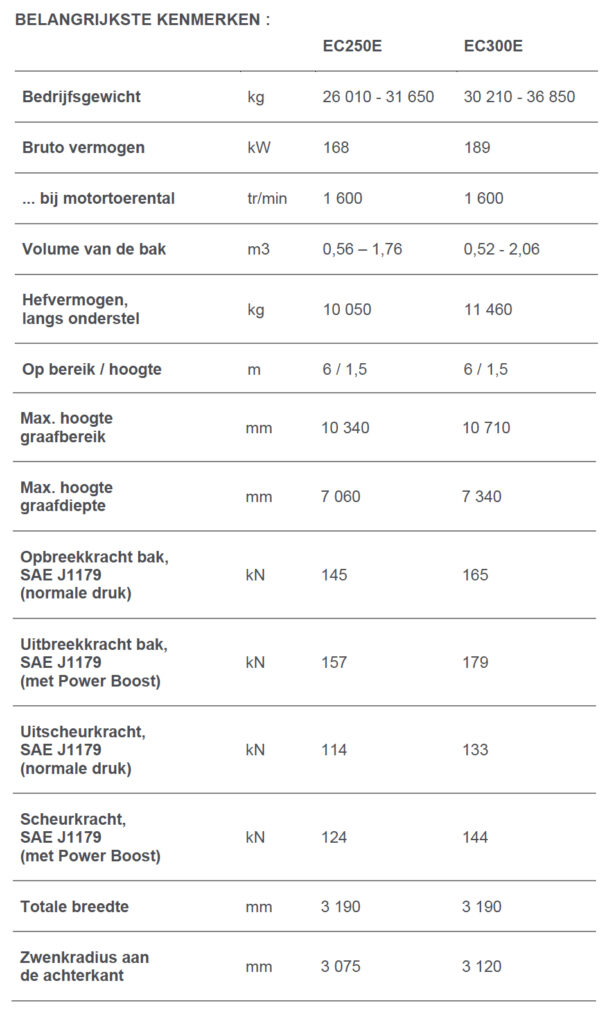

Volvo CE's new EC250E and EC300E excavators are heavy-duty machines weighing 26-31.5 tons and 30.2-36.8 tons, respectively. These upgraded models are equipped with the latest technology, new and proven features and can even come with special attachments to increase productivity and profitability. These durable Volvo excavators are safe, comfortable and reliable machines for your fleet.

MORE, MORE, MORE

These updated models are up to 10% more economical thanks to a combination of features such as a more intelligent electro-hydraulic system, classic ECO mode, selectable working modes and the new D8M Volvo engine. The new engine reduces engine speed from 1800 to 1600 rpm while increasing power by 5%. The new EC300E also has a new counterweight that is 700 kg heavier. As a result, the excavator now has greater stability and 5% more lifting capacity. Furthermore, the performance of both models has been improved thanks to new mobility priority functions. It is possible to prioritize one function, boom/turn speed or boom/travel, over the other with adjustable boom lowering speed control, ideal for precision work, and improved lifting speed.

Operators benefit from improved reaction times thanks to joysticks and all-electric travel pedals and are assisted by the optional Dig Assist applications (controlled by the Volvo Co-Pilot screen in the cab). These applications include 2D, In-Field Design, 3D, On-Board weighing, not to mention Volvo Active Control - which increases digging accuracy so that work up to 45% can be completed faster, thanks to automated boom and bucket movements. The operator can also easily set a swing limit, as well as a height and depth limit, to prevent hitting obstacles - overhead obstacles such as power lines and underground hazards such as pipes and cables.

COMFORT AND SAFETY

When designing Volvo machines, safety always comes first. Familiar features such as easy access points, bolt-on anti-slip plates, highly visible hand rails and the spacious, ergonomic and quiet Volvo Care cab provide the highest level of operator comfort and safety. To access the upper structure, operators can proceed safely and confidently thanks to the new 3-point access on the right side. Furthermore, rear and side cameras, along with the 360-degree Volvo Smart View option, allow the machine to run more safely, especially when working in tight spaces.

Operator comfort is also always a priority. Volvo takes this into account with a new technology that allows the boom and arm to spring back, reducing machine jerking. And to reduce fatigue, Comfort Drive Control allows the machine to be controlled with the joystick's thumb wheel instead of the pedals. Starting the work day has never been easier, with customizable settings such as choosing desired operating patterns via the monitor and a new "long-press joystick" feature that allows the operator to set up an additional shortcut function.

ATTACHMENTS

Volvo's quality attachments allow you to get the most out of your machine. Every job is different, but with specially designed attachments - such as buckets, breakers and more - you always have the perfect solution at your fingertips. With the new Steelwrist® quick coupler with automatic connection, you can easily connect hydraulic attachments from the comfort of your cab. And thanks to compatibility with Steelwrist®, Engcon®, Rototilt®, SMP® and OilQuick® tiltrotators, you can increase your productivity and dig from any angle. The factory-installed tiltrotator preparation system allows you to operate both the excavator and tiltrotator with the original joysticks, while displaying information on the main display. The performance and durability of all these attachments are secured by a 10% increase in hydraulic attachment cooling capacity.

SIMPLE MAINTENANCE

The new D8M Volvo engine builds on generations of proven Volvo engine technology and offers superior reliability. Maintenance requirements are also simplified thanks to automatic regeneration

of the engine and the redesigned hydraulic system that facilitates maintenance. The new hydraulic system has fewer hoses, requiring fewer couplings and increasing reliability. Maintenance time and costs are further reduced by doubling engine oil and filter change intervals to 1,000 hours. And when it's time to refill adBlue, the new splash guard makes refilling faster and easier while reducing the risk of spillage and subsequent corrosion.

Even the toughest working environments are no match for the Volvo EC300E and EC250E. Both machines feature robust undercarriages with reinforced intermediate wheels, track links and bottom rollers. Strength and durability are further supported by a reinforced bucket joint, an optional heavy-duty superstructure, undercover and easily replaceable wear plates.