The team with the leading hammer comes from Weert

When we talk about hammers, of course we are talking about demolition hammers. Very big ones, in fact. And the team with the biggest hammer is, of course, the team of Henk Saes, director and owner of Saes International BV. "As people have come to expect from us, we only go for the very best, affordable quality, performance and service," says Henk Saes. "That certainly applies to today's most popular demolition hammer, the 7-ton HB7000 from Epiroc of Essen, formerly known as Atlas Copco, intended for excavators up to 120 tons deadweight."

As many as 31 of these giants are under Saes in the Benelux. "This makes it the most common large demolition hammer in its class. With this number we even exceed the number of demolition hammers of this caliber present in Germany. In addition to these HB7000s, we have 5 more of our own in our standby rental fleet. This allows us to respond quickly and flexibly to questions that come to us from work."

The demolition hammer with the least failures

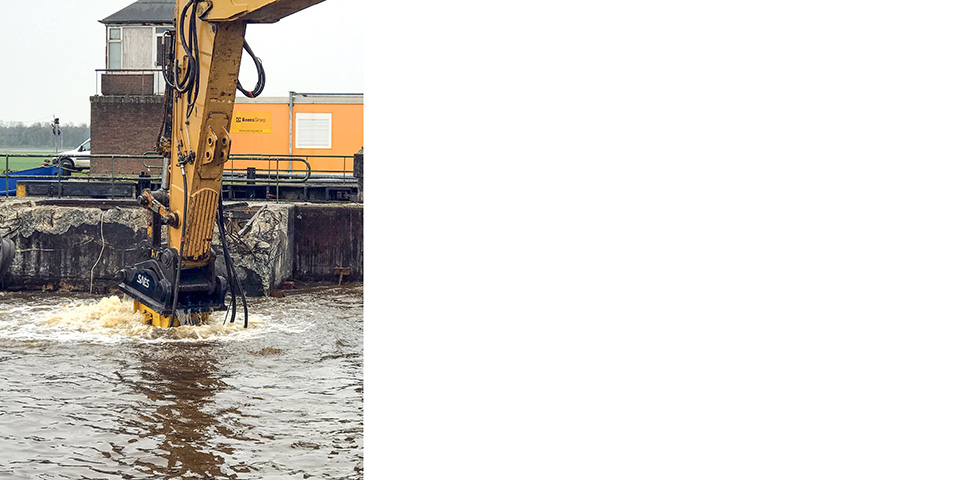

"The HB7000 is the demolition hammer with the fewest breakdowns and the greatest striking power," Henk opines. "In terms of productivity, this demolition hammer is unmatched. We also supply it with an underwater kit for the excavator, so it can be used wet. The PowerAdapt function protects the hammer from overpressure; instead of overloading, the hammer just stops. Recently, the IPS function has been added. IPS stands for Intelligent Power System, and indeed the system is really smart. On the first stroke, the hammer itself registers how hard the material being struck is. After that, the system constantly adjusts the striking rhythm and force of the blow to prevent empty blows and thus protect the equipment and promote efficient use. Because of this IPS (standard since July 2018), the energy saved can be reused for the next stroke. "So this makes the use a lot more sustainable. Work is done more efficiently and faster."

Epiroc training at Saes International BV in practice.

Fat stays in, dust stays outside

System protection goes even further than IPS. Dust Protection ensures a reduced wear process. Henk explains: "These HB7000 demolition hammers come with optional Dust Protection, which we ourselves, however, have fitted as standard. A steel, floating ring with plastic protective covers prevents dust and dirt from reaching the chisel bushings. Grease stays inside this way, coarse and fine dust particles stay outside."

The Epiroc HB7000 is deployed underwater.

Saes International BV is far ahead of the market with the products it offers the industry. So is the level of service: it is high. Henk takes pride in the fact that the team at Saes International BV keeps the client in the saddle in the event of emergencies: "We have an extractor that we use to drive to the workplace, if a chisel bushing needs to be replaced on site. A job that normally requires the demolition hammer to come back to the workshop, we now perform on site. Within four hours, our service people have exchanged a chisel bushing on site and downtime is minimized for our customer."

Saes International BV can call itself the market leader in the small and heavy segment, serving customers who use the equipment pieces for demolition, underwater work and quarrying. The support customers receive is phenomenal. "In return for that service, our customers are loyal to us. Large customers look for brands that are proven good and can be serviced wherever they are working at the time. We provide that cross-border support," Henk concludes.