The impact of innovation and sustainability on the evolution of the workplace

Industrial flooring has evolved enormously over the past two decades. What once began as a purely structural element is now a crucial factor in the success of modern warehouses and distribution centers. What has changed and what is the best industrial flooring today? We asked Daniël Toonen, senior sales engineer at Van Berlo Flooring. This flooring specialist has been combining craftsmanship with innovation for 45 years and sees every day how sustainability, circularity, and technology reinforce each other.

According to Toonen, the evolution of commercial flooring is a combination of technological advances and changing awareness. “In the past, flooring was a necessary evil,” he says. “In the 1990s, concrete was simply poured in areas measuring five by five meters or thirty by thirty meters. Over the past two decades, we have transformed from a product with little value and technology to a quality product in the broadest sense of the word.”

Mini Vibratory Piles

“In early 2000, Van Berlo started marketing a highly effective foundation pile for floors, known as the Mini Vibropaal. This is a compact, efficient, and cost-effective foundation pile for floors. It significantly lowered the threshold for choosing a high-quality foundation,” explains Toonen. “The solution is technically better and more attractive in terms of price. This has greatly improved the quality of floors in logistics environments.”

Digital progress

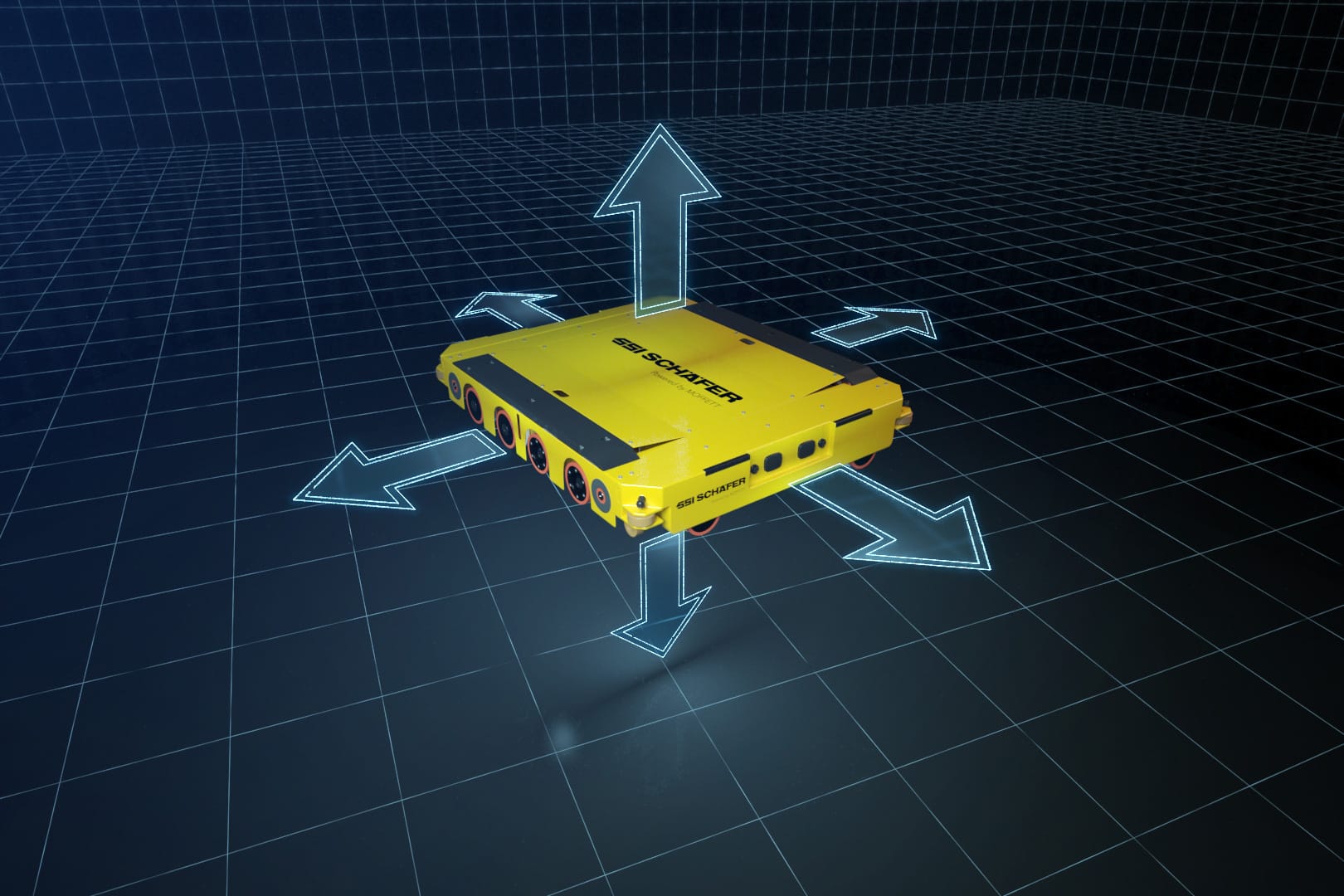

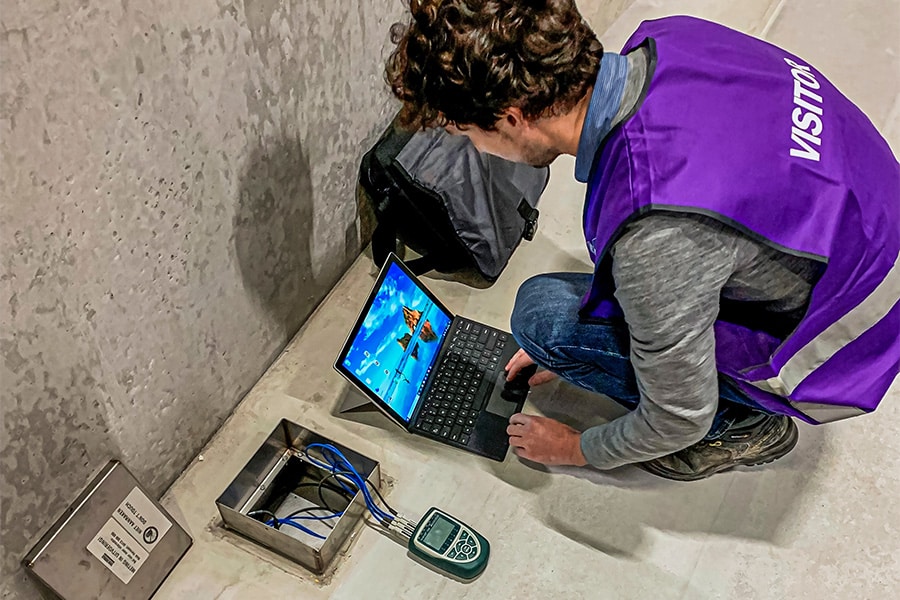

Around the same year, Van Berlo started developing the seamless floor with a consultancy firm. This offers numerous advantages. Toonen gives a number of examples: “Think of greater flexibility in terms of rack layout, lower maintenance costs, improved hygiene, and less wear and tear on equipment. But also the prevention of downtime and the safeguarding of business processes. Expensive robots and machines can only perform optimally on a floor that is flat, smooth, and stable. Advanced logistics technologies only function on a stable and flat surface. Every crack, joint, or other unevenness hinders the workflow. This also increases safety. Think, for example, of forklift trucks, which can be sensitive to unevenness in the floor in terms of balance.”

Durable and tear-resistant

Around 2016, Van Berlo, in collaboration with Eindhoven University of Technology, launched a study into improving floor quality. “Our goal was to develop floors that cannot crack. And we succeeded! But the technology that emerged from this also proved to make a significant contribution to CO2 reduction. This led to the development of our Greymatter technology, an optional solution that allows customers to further reduce their ecological footprint while also improving quality.” Toonen also points to the bigger picture: “The way a floor is designed ultimately determines the environmental benefits. Good design means less material, lower costs, and a lower impact on the environment.”

Team Abroad

The vast knowledge and expertise required to create a good industrial floor is currently still mainly a Dutch affair. “Our country is leading the way in this field. In many countries, this knowledge is still unknown.” That is why Van Berlo recently embarked on a new path: expanding its international brand awareness and developing a leading role as a knowledge center for sustainable and seamless floors. To achieve international expansion, a specialist team has been put together, of which Toonen is a member. Van Berlo has already installed various floors abroad, including in Belgium, Italy, Germany, Denmark, and England.