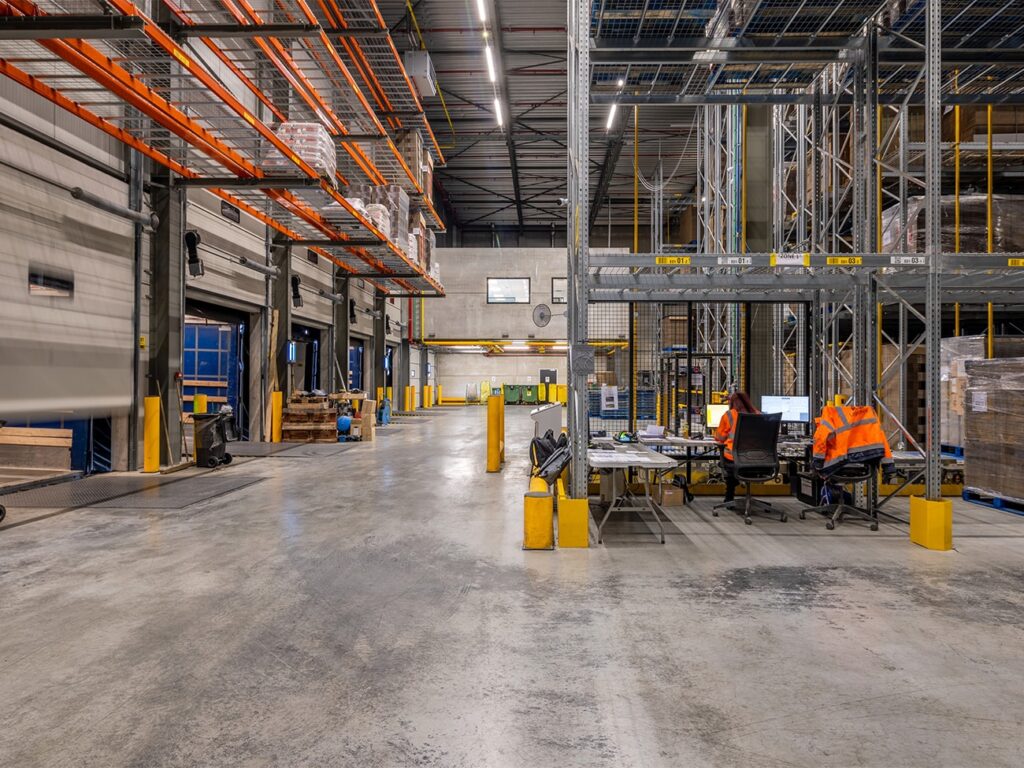

State of the art storage warehouse with loading pit and indoor office

Transport Bauwens & Son was founded in 1948 by Roger Bauwens. He started with one truck with which he himself transported cattle, racing pigeons and peat. Meanwhile, the third generation is at the helm of the family business. Thanks to the many transport activities and GMB, the logistics activities have grown enormously. That is why the company built a new storage warehouse with loading pit and office on its site in Turnhout. A building that was realized like a tailor-made suit by the expert contractor.

In three quarters of a century, Transport Bauwens & Son has evolved from a household name in Stekene to a household name in Belgium. The company currently has two hundred employees, six warehouses and a fleet of one hundred vehicles. In 2020 and 2021, the logistics pillar in particular was further expanded, including through the establishment of warehouses in Veurne, Evergem and Turnhout. The latter location is mainly used for the distribution of corrugated cardboard, produced in Smurfit Kappa's factory at Veedijk in Turnhout. Because the existing infrastructure was no longer adequate, a complete new building with automated racks was needed to increase efficiency and capacity. The open warehouse, with a loading and unloading area at the front, has loading docks that lead into the processing and storage area. On the front left side is an indoor office with digital reception, ground-level user areas for co-workers and an upper landscape office overlooking the warehouse.

More than just building

The entire site was completed in June 2021. "In this project, our task was much broader than just effective construction," says Gunter Vermeulen, commercial manager at contractor Bolckmans. "In addition to our construction expertise and specific construction methodology, we also immediately involved our partners for the logistics processes and flows. In this way, we managed to significantly reduce the construction cost." Leo Potters, who together with Stef Loos managed the execution team, adds: "Our specific task was to implant - on a limited area - a building with a maximum number of pallet locations and minimal logistical interference and operations. In addition, it was Bolckmans' task, as part of the construction team, to merge the knowledge of all parties from the initial phase of the project, so that the right decisions could be made in time in terms of budget, timing, degree of finishing and so on."

Open and constructive communication

Bolckmans thought constructively and proactively with its client. Gunter Vermeulen: "Already during the preliminary project, consultation moments were organized on a weekly basis. These moments increased in frequency and intensity as the start of the works approached. During that period, our internal Architecture Department worked closely with an external architect to implement our building methodology in the design. Because all parties were involved in the process so early on, we were always able to test the plans against the various disciplines at each step in the design (for example, also the installation of the mobile racks)."

"We always communicated openly, transparently and constructively to arrive at the most interesting and optimal solution for the client," said Leo Potters. Everything had to be realized in a particularly tight time frame, so that the successive parties/contractors for WMS (warehouse management), IT and computer systems also had the necessary time available to implement their installations."

Thorough preparation

"No unexpected difficulties surfaced because Bolckmans invariably designs and coordinates a building as a tailor-made suit for the customer," Gunter Vermeulen clarified. "Based on a BIM model, the project was first worked out virtually down to the smallest detail before going into production. It is precisely thanks to this thorough preparation that the execution team was able to realize everything quickly and without problems. Because the manager is very much involved in the daily follow-up of his transports and customers, our biggest challenge was to relieve the customer of all his worries. This allowed him to use his precious management time for his core business. Quality work was therefore a must, as was trust. We are not satisfied until the customer is!"

- Bouwheert Transport Bauwens u0026 Son (Stekene)

- Architectt Architectural firm Frank Joosen (Schoten).

- Main Contractor(s) Bolckmans (Hoogstraten)