Smarter logistics starts with every component

Spare-parts logistics is all about speed, accuracy and availability. Parts that barely move must still be on standby at all times, while any kind of downtime costs money immediately. Pressure on warehouses is increasing, but smart automation technology offers opportunities to turn this complexity into real competitive advantage.

Automation changes the rules of the game

Warehouses that work intensively with spare parts notice it daily: demand is unpredictable, inventories are diverse and errors have a direct impact on customer relations. Automation therefore plays an increasingly important role in streamlining these processes.

In modern warehouses, repetitive tasks are being taken over by robots and digital systems. Think modular solutions that are easy to scale up, ergonomic workstations that reduce physical strain, and intuitive interfaces that allow new employees to be quickly inducted. This not only reduces reliance on specialized knowledge, but also makes work more consistent and safer.

Tools such as pick-by-light, automated storage locations and AI-driven software significantly reduce errors. The result is higher productivity and a process that is much less susceptible to human variation.

A visible effect on ROI and customer experience

In spare parts logistics, reliability is at least as important as speed. Every error, whether mispicks, returns or repackaging, adds costs and can strain customer relationships. Automated systems often reduce such errors by tens of percent, which is immediately reflected in performance.

In addition, technologies such as sensors and IoT platforms provide real-time visibility into the status of orders, inventory and robot activity. Managers can intervene faster, adjust processes and recognize trends. This reduces indirect costs and increases customer satisfaction because orders are delivered not only faster but also more consistently.

Availability remains the key here. Customers want parts when they need them. Price plays a role, of course, but the ability to deliver reliably time after time determines true loyalty. Automation enables that reliability on a scale that is simply not achievable manually.

Flexibility as a strategic advantage

For most aftermarket companies, growth is not linear. Seasonal peaks, new product lines or an unexpected increase in demand can put firm pressure on warehouses. Flexible, scalable automation is therefore essential.

Modular systems, such as robots that move vertically and horizontally through the warehouse, can be easily expanded without prolonged downtime. Companies do not have to install full capacity immediately, but can invest according to a ‘pay as you grow’ model. This better aligns costs with the real growth of the organization.

Spare-parts players such as Renault, AAG and ILS show that this approach works. Many automation projects reach their break-even point within two to three years. At the same time, maintenance costs and operational risks decrease while service levels increase.

The result is a warehouse that not only runs more efficiently, but is also more future-proof.

How Exotec is making a difference

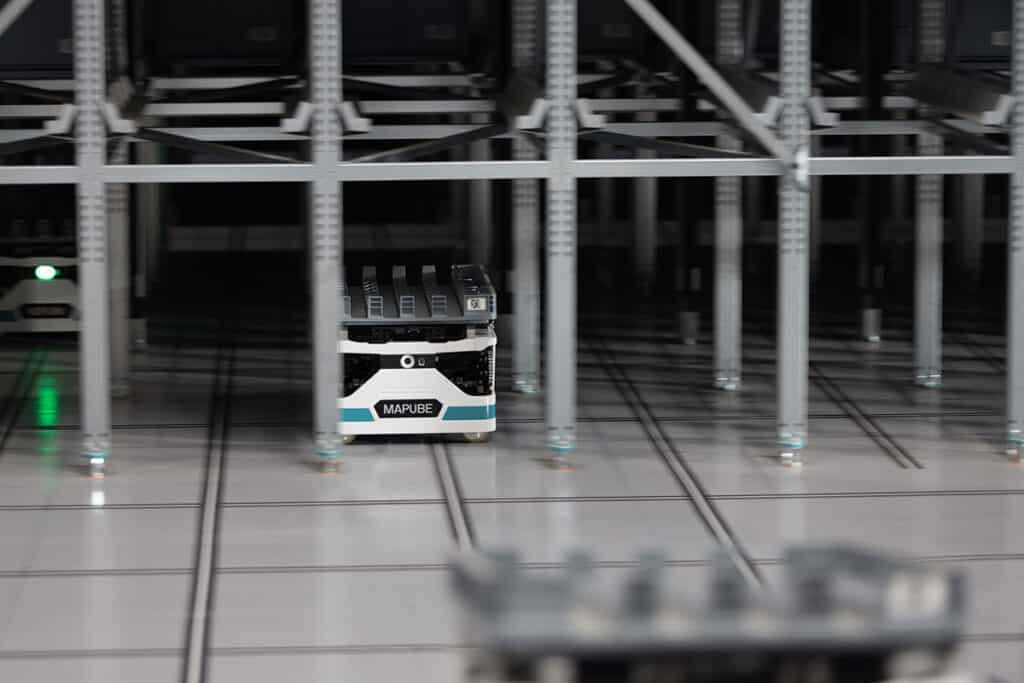

Exotec develops technology specifically suited for environments where availability and accuracy are critical. The Skypod System is designed for companies that manage many different components and have no room for errors or delays.

The autonomous Skypod robots retrieve totes directly from storage racks and bring them to employees. This eliminates the need for employees to walk through the warehouse. The system comes to them. This speeds up picking, reduces errors and ensures consistent flow, even during peak times.

Moreover, the architecture of the system is completely modular. New robots, additional storage racks or workstations can easily be added without major remodeling. This makes the system ideal for organizations looking to grow without operational risk.

For spare-parts logistics, this means:

- Faster order processing

- Fewer errors and returns

- Better inventory availability

- Lower operating costs

- Flexibility to move with the market

In an industry where downtime immediately means lost sales, Exotec offers a powerful answer to today's and tomorrow's logistics challenges. Spare-parts logistics requires a combination of speed, availability and reliability. Smart automation, like Exotec's, makes it possible to combine those elements and turn complex processes into a strong, sustainable competitive advantage. With modular technology, real-time visibility and scalable robotic systems, the warehouse becomes an engine for growth, not a cost center.

Want to take your spare-parts logistics to the next level? Download here Exotec's latest Supply Insights.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Exotec.

Contact opnemen

Contact opnemen