RAVAS wins prestigious IFOY Award for Weigh In Motion technology

Modern logistics is all about managing material flows. It constantly requires as much information as possible about these flows. With a weighing system, built into a pallet truck, electric pallet truck, stacker or forklift, you tackle this thoroughly. RAVAS has been a leading player in this mobile weighing technology for many years. In the spring of 2024, the company won a prestigious innovation award. CEO Guy Henckaerts has a clear strategic vision to realize the company's ambitions.

The world of "material handling" is in a state of flux. Mobile weighing systems have become indispensable tools for making intralogistics processes more efficient and cost-effective. After all, they save entrepreneurs valuable time, money, space and manpower. "More than ever, modern logistics is about managing material flows, with data management as the guiding force," says Guy Henckaerts. "The (cost-)efficient management of material flows requires a maximum of information. How much stock do you have of a particular material? Where is it located? Where does it come from and where does it go? Where was it produced? With RAVAS, we offer logistics market players and their customers numerous mobile weighing solutions that provide clear answers to these and other questions."

Measuring is profit

In a previous edition of this magazine, we illustrated this with a simple calculation example. Anyone who weighs an average of four pallets per hour will save an average of one and a half minutes per pallet if he uses a RAVAS weighing system built into the transporting truck for this purpose. This results in a daily time savings of 48 minutes, or 200 man-hours per year. At a cost of roughly 25 euros per man-hour, this translates into a saving of 5,000 euros per year.

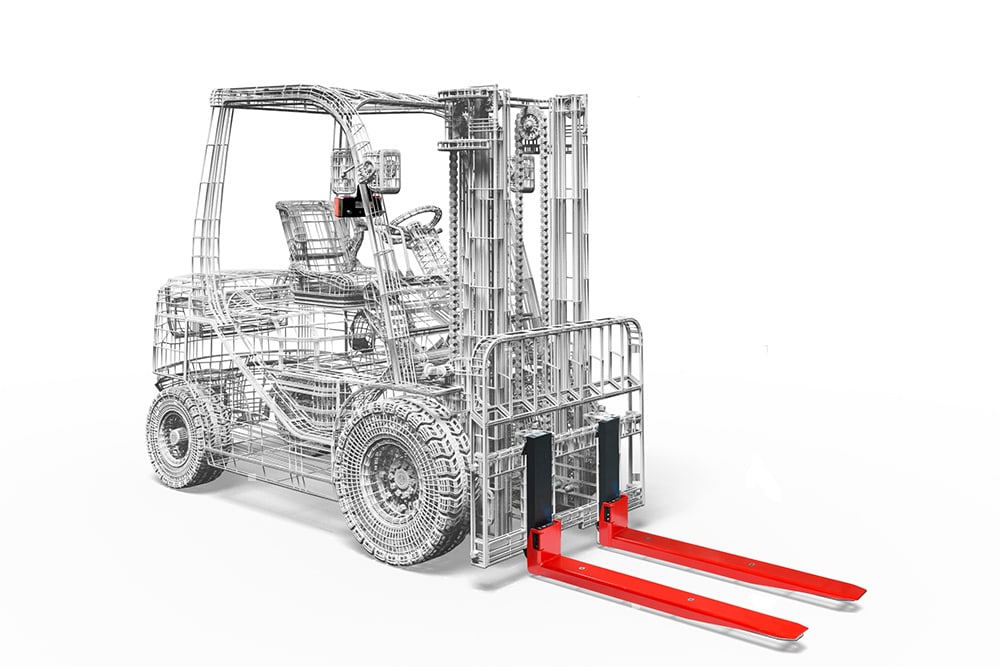

"With in-house teams in eight European countries and the United States, we have the necessary experience and expertise to build our weighing and measurement technology into forklifts, hand pallet trucks, electric warehouse trucks and stackers," Guy said. "Real-time material flow data is transferred directly to TMS, WMS or ERP business systems. Within our customer base, we see a clear evolution toward the most accurate zero measurement possible for so-called 'point of entry' loads. This involves clear mapping of weight, dimensions and other values. Many logistics companies bill their operations based on pallet weight. So the more accurate the figures, the more profitable a business activity becomes. With RAVAS, we can play an important role here."

Wide range of USPs

Among European logistics players, the name RAVAS rings a bell. According to Guy, what are the company's most important USPs? "A major strength is our wide range of weighing solutions that can be used for different logistics and production locations. This ranges from ATEX-certified weighing and measuring systems that may be used in hazardous areas to systems for the food and pharmaceutical industries. At the same time, we push hard for excellent after-sales service, with SLA commitments for reliable hardware and software support. With our own engineering team, we are happy to work out customized customer solutions, such as, for example, the combination of a wrapping film machine and weighing device, or a manual order picker with built-in weighing platform. Furthermore, we make privatelabel products for OEMs, which boosts our brand awareness and reputation in the market. Last but not least, all of our solutions are manufactured in Europe. This local approach allows us to move quickly in terms of delivery times, to the great satisfaction of our customers."

Weigh In Motion technology awarded

That RAVAS is a leading player in its niche was also evident in the spring. That's when the company won the prestigious IFOY Award for its Weigh In Motion technology. "IFOY stands for 'International Forklift Truck of the Year.' The award is great recognition for our technology on an Intelligent Carriage Plate (iCP), developed specifically for forklifts," Guy explained. "We officially launched our Weigh In Motion at the LogiMAT trade fair in Stuttgart, in March of this year. Thanks to this technology, a forklift operator can weigh loads precisely without having to stop. This avoids unnecessary and time-consuming transport movements and also increases safety on the shop floor. It is yet another important step with which we are moving logistics and industrial companies forward."