Exciting logistics trade fairs set the sector in motion

More than three hundred exhibitors and 8,500 visitors in three days

Robotics, AI, RFID, and more than three hundred exhibitors and 8,500 visitors in three days. Logistica Next and ICT & Logistics at the Jaarbeurs in Utrecht pulled out all the stops to inspire the logistics world and get companies thinking about the next step toward greater efficiency.

The two logistics trade fairs are becoming increasingly aligned. Logistica Next was once primarily the showcase for large intralogistics solutions, with racks and forklift trucks. For years, ICT & Logistics presented itself as an event with stands where the solutions and applications were barely visible, but the solutions behind the scenes were oh so important. Since 2024 and also in 2025, these two worlds have become clearly intertwined. Robotics, such as AMR and AGV, but also AI, RFID, and software control were prominently featured at both trade fairs. These have become indispensable elements for fulfillment, intralogistics, distribution, and production.

Data, technology, and responding to change

The goal of virtually all exhibitors was to stimulate visitors. The trade fair organizers added substantive sessions, with a strong emphasis on data and AI. This is no longer a luxury, but a necessity in order to respond to market changes. The multitude of solutions and sessions gave visitors the opportunity to gather tips and orient themselves on the choice of a TMS, WMS, or robotics solution.

Intralogistics

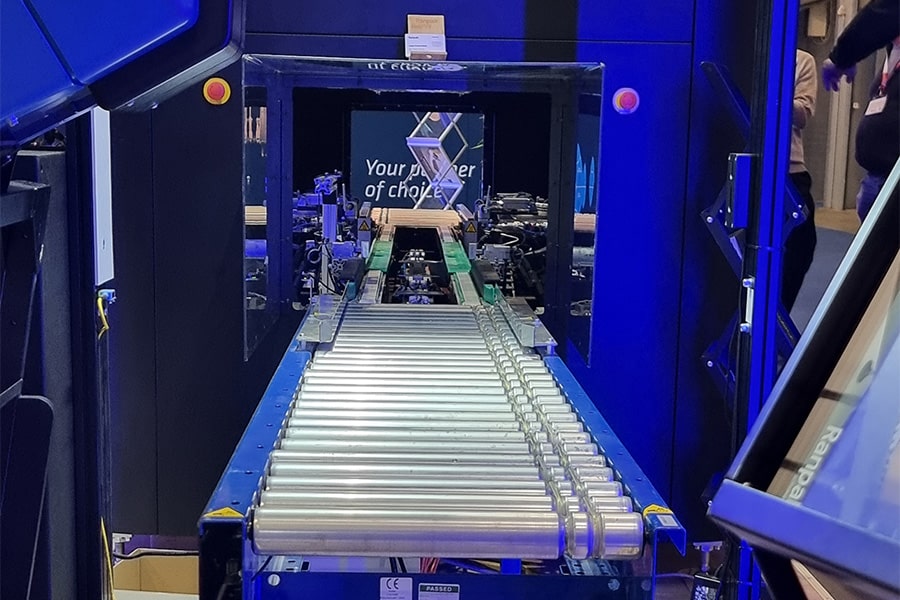

A large number of entrepreneurs are currently looking for ways to respond to the labor shortage in logistics processes and, at the same time, make these processes more flexible. This is probably the biggest intralogistics challenge at the moment. In practice, this development boils down to targeted investment in a form of automation that can work together with warehouse staff, for example, when desired. Application-driven robotics combined with roller conveyors or conveyor systems were therefore also widely represented. This is an example of a system that can, in principle, run 24/7. Various suppliers demonstrated the possibilities, from pure robots to Autostore systems. Several examples of this can be found in this and the previous edition of Warehouse & Logistics.

RFID and AI

Efficiency is, of course, more than just getting intralogistics tools and people to work together; it also means providing certainty, such as the certainty that the right package ends up in the right truck. RFID is playing an increasingly important role in this, and sometimes even a combination of RFID and AI. In any case, Logistica Next and ICT & Logistics would have been unthinkable without AI, especially because AI is capable of interpreting larger amounts of data or unstructured data. The technology can thus speed up processes, but above all take over manual tasks from an already scarce workforce. For example, when it comes to processing orders, invoices, or scanning items.

Data quality

One aspect remains, something that virtually every supplier at the trade fair agreed on: the possibilities for working smarter, more efficiently, and with fewer errors are there, but the quality and completeness of the item and company data determines the degree of efficiency that can be achieved. This is not a new topic, but it is one that will distinguish one company from another.