Optimized UV solutions

Berson UV Techniek in Nuenen has been a pioneer in UV disinfection technology for drinking water and wastewater applications since 1972. Together with Hanovia from the United Kingdom and Aquionics from the United States, Berson forms the Halma UV Group. They belong to The world's leading suppliers of UV disinfection technology. A conversation with John van Miert, Regional Director EMEA and Danny van Kuringen, Regional sales manager EMEA about recent developments and expanded after-sales activities.

"In 2017, the decision was made to unite the three companies and combine operations," Van Miert said. "We operate as one company with three sales and after-sales regions: EMEA (Europe, the Middle East and Africa), Asia and the Americas. That way we are closer to our customers, virtually in the same time zones and can therefore anticipate more quickly."

Berson UV Technology supports its customers at all stages of their "UV journey.

Application optimized UV

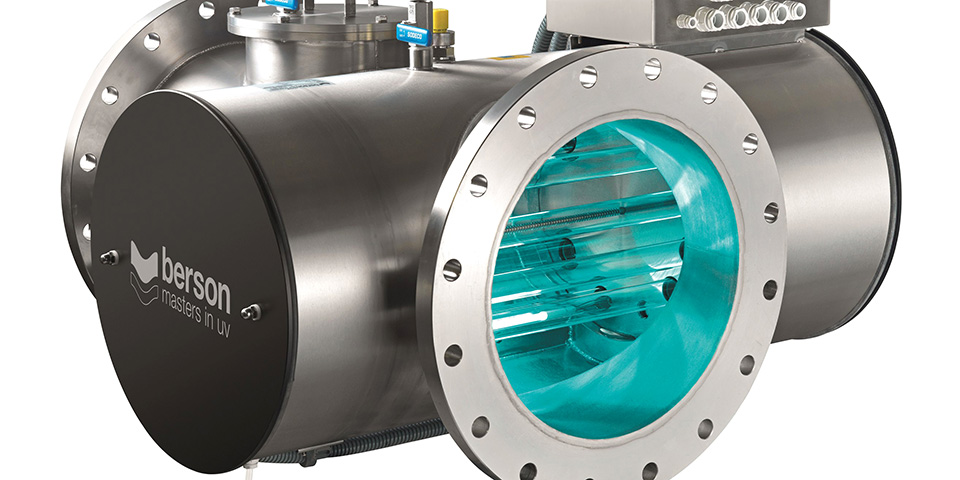

The distinguishing feature of the Halma UV Group is that both the UV lamps and the systems are developed and produced entirely in-house. Van Miert: "In this we are unique. That means we are able to optimize our technology and system design for the application for which it is intended: application optimized UV we call that in 'good Dutch'."

The group's product range offers solutions for industrial and municipals applications. Industrial applications are very diverse and mostly found in the food industry, pharmaceutical industry, at water parks and swimming pools, fish farms, ships, etc. Municipal applications consist of installations for drinking water, wastewater and water reuse. Van Miert: "Although we use the term industrial to broadly separate this product range from UV systems for application at municipal facilities, we fundamentally believe that there is no such thing as a uniform industrial UV. UV technology is always tailored to the situation. Flow rates, power levels, UVT levels, target organisms, fit and function such as connection types, internal finishing specifications and electrical specifications are all variable parameters in this."

In addition to UV disinfection technology, the group is also developing UV technology for dechlorination and ozone reduction. Van Kuringen: "With UV, we can inactivate microorganisms, interrupting the DNA string in a cell so that the cell can no longer divide. We can also use UV to reduce ozone or chlorine to a certain level, making it harmless to filters and membranes in an industrial process. In other words, we provide the best UV support available, regardless of the situation or application."

WeUVCare

"We support our customers at all stages of their 'UV journey. "That's what we mean by WeUVCare," Van Kuringen explains. "And in this we go far. Customer service already has our full focus and is supported by local and digital initiatives. Thus, our service platform is being expanded in phases. Our web application is at the center of this: manuals and technical data sheets, a list of service parts, scheduled maintenance recommendations, self-help programs, training and service videos, it will all soon be available on it. Needless to say, we also provide our customers with advice and assistance from the regional hubs and local certified partners."