Movu Robotics' Experience Centre: more than just customer visits

Flexible and strong collision protection also in the spotlight

A very interesting movement took place on the "fringes of warehousing" this year. West Flanders racking giant stow let its robotics division stand on its own legs - or is it wheels? - on its own. The reason is quite simple. The market for "material handling" is estimated at no less than 140 billion euros worldwide. And Movu Robotics - as the little green robots will go through life from now on - is going for no less than a substantial part of that. Say we said it ...

On November 23, A-Safe, together with Movu Robotics and media partner 'Warehouse & Logistiek' (Louwers Media Group), organized a knowledge and networking event for warehousing and the logistics sector. They wanted to bring interested partners together at Movu Robotics' brand new operating base in Lokeren. In order to meet and share expertise.

The shared future of scaffolding and robotics

The richly filled morning was kicked off by an ambitious Stefan Pieters, CEO Movu Robotics: "Movu Robotics and stow Racking have a mutually enriching relationship. Movu Robotics, although fully part of the stow Group, functions as an independent unit working intensively with the racking experts within the group. This internal cooperation enables us to leverage our knowledge and expertise in rack construction to fully optimize rack systems for specific applications. Customers benefit from this through integrated project management, aligned logistics, uniform processes and systems that ensure reliable deliveries and an efficient supply chain. And you can see that in the numbers. This year we are running close to 100 million, and we plan to double this next year."

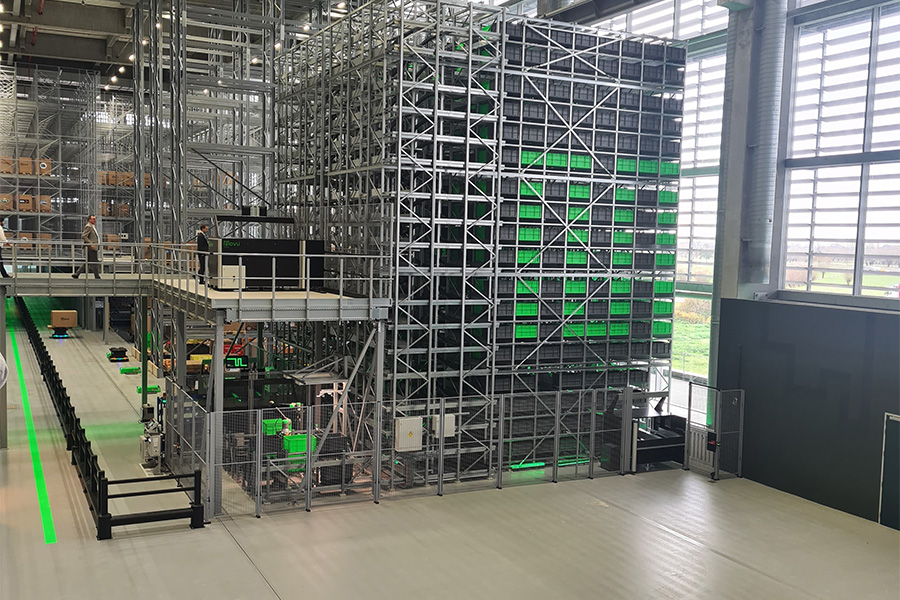

"This close collaboration enables us to deliver unique performance," continued Karel Boone, Group & Robotics Sales. "And that is clearly visible in our Experience Centre. Here everything was integrated into a demonstration rack, including a tunnel under that rack, a staircase that goes around the vertical elevator, and a mezzanine with a gathering space. There you can see both the Movu atlas, Movu ifollow, Movu escala and the brand new Movu eligo hard at work."

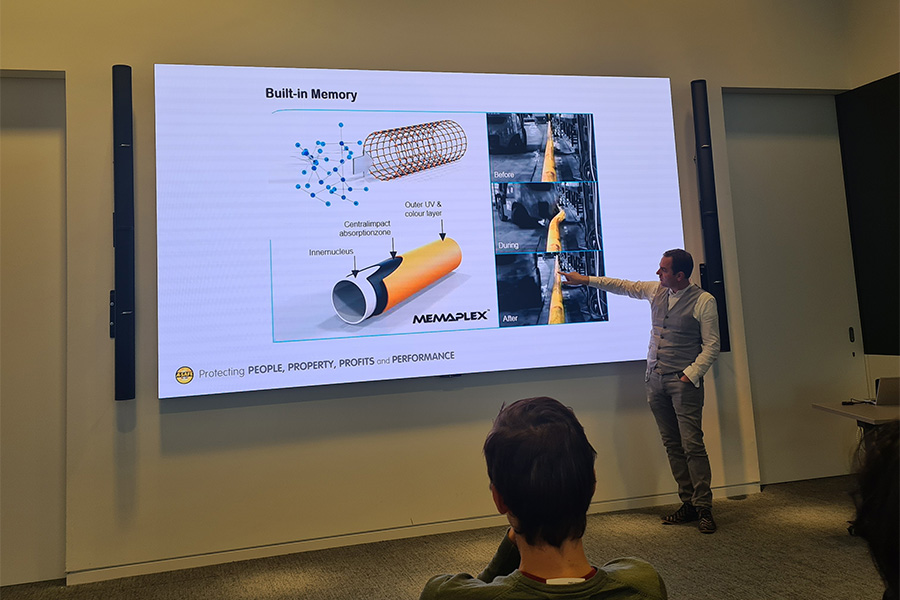

MEMAPLEX™: from R&D to reality

Both presentations were followed up and concluded by an exciting presentation of A-Safe Belgium and their MEMAPLEX™.

Dries Aneca, Sales Manager A-Safe Benelux: "MEMAPLEX™ is a material developed by our R&D department, with very special molecular structure. This makes it both flexible and strong. The impact protectors are designed to fully absorb the energy of a collision. As a result, minimal force is carried out on the bolt fasteners and the floor, resulting in significant damage reduction. The specially developed fasteners and installation methods are suitable for all types of floors. The collision protection is flexible and fully modular, meaning that rails and posts can be easily replaced or expanded after installation. Ideal for securing shelving structures and handling robots from stow and Movu, respectively, in short!"

Enlightening tour

After these fascinating presentations, it was time for a detailed tour of Movu Robotics' impressive Experience Centre. And that was well enjoyed by the many attendees.

"The Experience Center serves not only for customer visits, but also as a hub for hosting industry groups, hosting workshops, and exploring trends and market developments. It allows us to demonstrate in real-time and in a dynamic way what is currently possible and how we can anticipate future needs," concludes Stefan Pieters.