Discover the RAVAS iCP Performance: Higher safety and maximum lifting power in one smart system

Safety is paramount in any forklift operation. Yet that safety often comes under pressure when additional functionality is added. Traditional combinations of weighing systems and attachments add weight, limit visibility and reduce residual capacity. As a result, the forklift tilts up faster, can lift less load and is more likely to collide. On top of that, they involve fragile cables, complicated calibration processes and high maintenance costs.

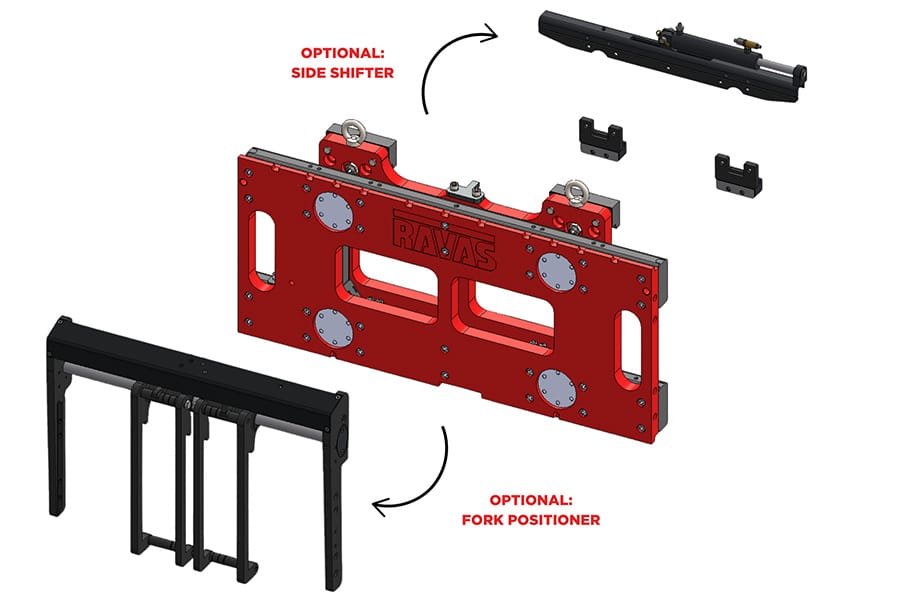

With the introduction of the RAVAS iCP Performance, RAVAS is breaking through this logic. This, together with TU/e alumni newly developed, weighing fork board combines accurate mobile weighing technology with an integrated fork positioner and side shifter (both optional), with minimal concessions on lifting capacity, visibility and safety. Smart technology and active warnings even actively increase safety, both for the operator and the load. The result? Maximum performance, lower operating costs and an unparalleled user experience.

New design with maximum lifting performance

Traditional combinations of weighing systems and attachments are often accompanied by technical limitations: additional weight and greater mounting depth lead to loss of capacity and worse visibility for the operator. The RAVAS iCP Performance addresses this at the source with a completely new mechanical design.

Thanks to its lightweight, slim construction, the truck's residual capacity remains virtually intact. Operators can therefore lift more load with the same truck than with comparable systems. The slimmer frame is optimized to provide better visibility of the pallet, load and pallet corners without the operator having to hang next to the truck. This increases both safety and efficiency.

The electronics are fully integrated into a robust metal frame while maintaining wireless connections. This prevents cable breaks, reduces the chance of downtime and contributes to the high reliability of the system. As you would expect from RAVAS, the design is built to high safety standards.

Smart technology: 2D load cell and easy calibration

With patented 2D load cell technology, the RAVAS iCP Performance introduces a new standard in mobile weighing systems. Where traditional systems only measure weight, the iCP Performance shows in real-time how the load is distributed across the forks. Drivers immediately see whether the load is safely positioned and receive real-time, active warnings in case of a dangerous center of gravity.

Maintenance and calibration have also been greatly simplified. Mechanical flexures have been replaced with extra durable, maintenance-free components. Calibration is done electronically via the RAVAS RedBox, making the process faster, simpler and less dependent on specialist knowledge.

Thanks to this new approach:

- Is the system quicker to maintain and thus quicker to get back up and running.

- Can even technicians with less experience easily perform maintenance.

- Becomes instantly visible where problems are via digital diagnostics.

These improvements not only reduce costs, but also minimize truck downtime in operations.

Modular Features

The iCP Performance is designed as a modular system and prepared for the integration of a fork positioner, side shifter and height sensor. These options can be included directly or easily added later, without separate attachments (bolt-on).

The in-house developed RedBox display shows not only the weight, but also the position of the load on the forks. Visual warnings make it immediately clear when the load is outside safe limits, significantly increasing safety during operation.

Optional extras:

- Side shifter: With an integrated side shifter, the operator easily positions pallets against walls or in tight corners without much maneuvering. This saves time, prevents damage and maximizes space utilization.

- Fork positioner: The fork positioner is ideal for a variety of load sizes. From the cab, the forks can be adjusted automatically, saving time and preventing physical strain.

- Height sensor: The optional height sensor prevents damage to gantries and racks. If a set maximum lifting height is exceeded, the system alerts the operator immediately.

Full connectivity

The iCP Performance is fully compatible with modern logistics processes and integrates effortlessly into the digital chain. Via wireless communication, you can link the system with WMS, TMS and ERP platforms. Weight information, time stamps, product codes and user data are registered automatically, eliminating manual entry and preventing errors. For those who additionally need paper recording, an optional wireless printer is available.

The iCP Performance is compatible with the entire RAVAS Data Management Suite, including:

- RAVAS Indicator App

- RAVAS Data Collector

- RAVAS Integration Software

The system is also prepared for markets where "Legal for Trade" or "NTEP" is required: an OIML-certified version is under development.

Uniquely, the iCP Performance continues to continuously improve itself via over-the-air updates for which the user does not have to do anything. Both the display and the scale receive new functionalities, design improvements or additional options remotely - without physical intervention or downtime. Examples include new functionality, even more accurate weighing or security updates.

Innovation without compromise

With the iCP Performance, RAVAS sets a new standard in internal transport. The innovative 2D load cell technology and electronic calibration ensure maximum accuracy and safety. In addition, thanks to the lightweight and slim design, lifting power and visibility remain at a maximum.

The modular design with integrated side shift, fork positioner and additional options such as a height sensor make the system perfectly tailored to practical requirements. In addition, the RedBox display provides real-time insight into load distribution and safety. The far-reaching digital integration and over-the-air updates guarantee that the iCP Performance not only excels today, but also continues to evolve for tomorrow's requirements.

With the iCP Performance, RAVAS delivers an intelligent, robust and future-proof solution that proves that innovation and practice go together perfectly. Without concessions.

The RAVAS iCP Performance will be available starting in Q3 2025. For more information, contact marketing@ravas.com.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met RAVAS EUROPE BV.

Contact opnemen

Contact opnemen