LogiMAT 2025 shows a sector in full gear

LogiMAT 2025 proved that the logistics sector is not only alive, but vibrant. With a record number of visitors and a remarkably high quality of talks, Stuttgart was once again dominated by automation, flexibility and scalability. What stood out: solutions are becoming more compact, smarter and faster. From safety gates to climbing robots - an anthology of what impressed.

Where warehouse safety used to be an afterthought, today the topic is at the forefront of the agenda. This was evident at Haagh Protection, where the VarioGate - a certified fall protection solution - attracted a great deal of attention. "Companies are increasingly realizing that safety does not tolerate compromises," says Kay Mullenders. "Customers also expect that customization can be delivered quickly, or a standard product that is readily available from stock."

Sorting technology: more compact, smarter, faster

Sorting systems continue to evolve, and this was clearly underlined at LogiMAT. Collo-x presented the MicroSorter: a compact, modular sorting machine that processes up to 1,500 products per hour - from medication boxes to shoeboxes. The system builds on the PharmaSort concept and meets the growing demand for customized solutions in confined spaces. The demo at the booth attracted remarkably targeted visitors, often after an initial digital introduction. According to Floris Hendriks, the reactions were "mega positive," partly because of the versatility of the system, which can be used in both e-commerce and institutional pharmacies.

At Stöcklin Logistics, the focus at LogiMAT was on the new CasePicker solution: a scalable, fully automated system for direct picking from article pallets to store-mix pallets. Designed for food retail, stationary retail and micro-fulfilment centers - also in refrigerated areas above 0° C - the system achieves a capacity of up to 150,000 packages per day. With this, Stöcklin underlined its role as an end-to-end intralogistics partner, with total solutions that go beyond hardware alone.

EuroSort put the focus on efficiency within a limited space, with the launch of the Proto-E. "We address the specific needs of e-commerce customers, where there are many small orders that need to be processed at lightning speed," said Nivin Adjan of EuroSort. "The Proto-E combines a minimal footprint with the ability to operate multiple sorting outputs simultaneously - similar to the speed of a Split Tray Sorter, but in an even more compact size."

Both systems meet the growing demand for scalable, modular sorting that integrates seamlessly into existing infrastructures. They align perfectly with the overarching LogiMAT theme: doing more with less space - and without sacrificing speed or precision.

NDW Rollers showcased a new sorting solution with motors, controls and modular units focused on the last mile. "Our strength is precisely in that last mile: fast and efficient sorting of parcels, polybags and more," stated Patrick Sprangers. NDW had the systems working live, rather than a demo on screen, which resulted in a remarkably high number of quality leads.

Automation without barriers

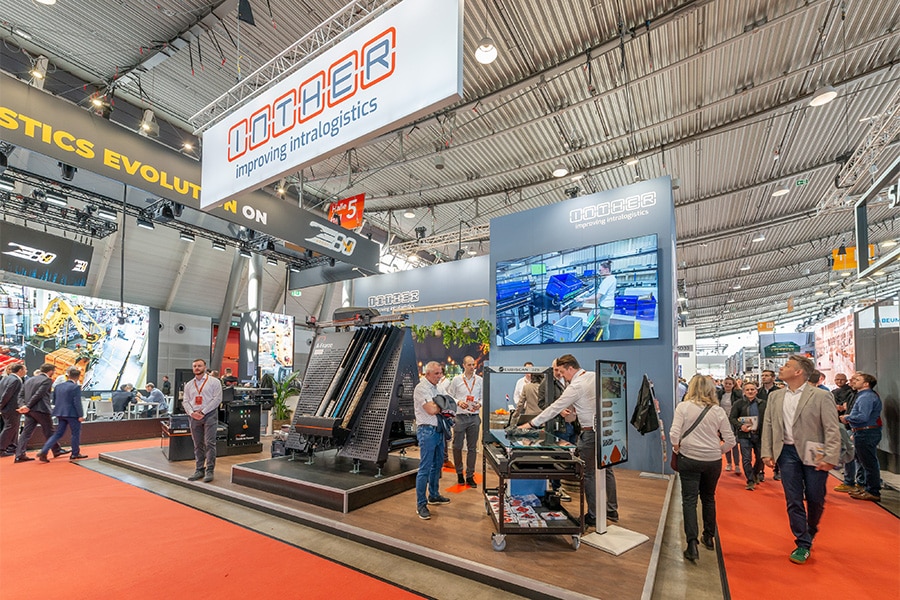

Automation was presented at this edition as accessible, modular and practical. Inther Group demonstrated this with the A-Frame as a fully automated solution for the rapid processing of complex orders, the user-friendly goods-to-person picking station and the Cubiscan, which measures and weighs products and links them directly to the WMS (Warehouse Management System). "No long training sessions are needed, just a good interface," Raymond Poulssen emphasizes. "Especially in tight labor markets, this is a strong advantage."

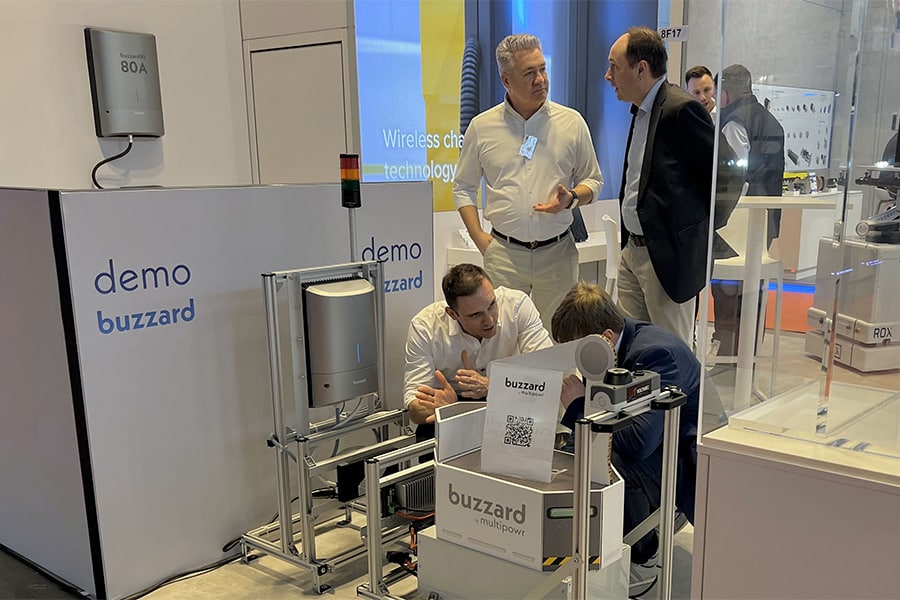

Multipowr was also fully committed to accessible technology, but in a different domain: wireless charging. Their participation in LogiMAT 2025 revolved around the Buzzard120, a powerful system for wireless charging of industrial vehicles. OEMs and logistics operators showed great interest, mainly because of the higher current ratings and the greater distance that can be bridged between charger and vehicle. According to Peter Besard, confidence in wireless charging systems is growing. "We notice that more companies are considering the switch, especially now that our technology is proving that it can be reliable and perform better than classic contact systems."

Smart packaging on sustainability

A lot is also moving in the packaging field. Packsize presented the X6, a high-speed packaging machine that produces fully customized boxes of up to 1,500 pieces per hour. The link to the upcoming European PPWR regulations is obvious. "Companies want to anticipate. With the X6, they can do that at the same time logistically and ecologically," said Ton de Graaf. The X6 not only enables smaller packaging but also increases processing speed in fulfillment centers, reduces packaging volume and avoids unnecessary air transport. The option to also make tray and lid combinations opens up new markets such as fashion and pharma.

Software as an engine of flexibility

Software is seen more than ever as a strategic lever for resilience. Pieter Van den Broecke of Manhattan Associates saw strong interest in the Manhattan Active suite. "The market is looking for solutions that combine flexibility and automation. And that requires intelligent software." The digital acceleration within supply chains, amplified by previous disruptions, is making companies look more critically at scalability and interoperability of their systems. Manhattan is responding to this with cloud-native software that quickly integrates with warehouse and transportation technologies.

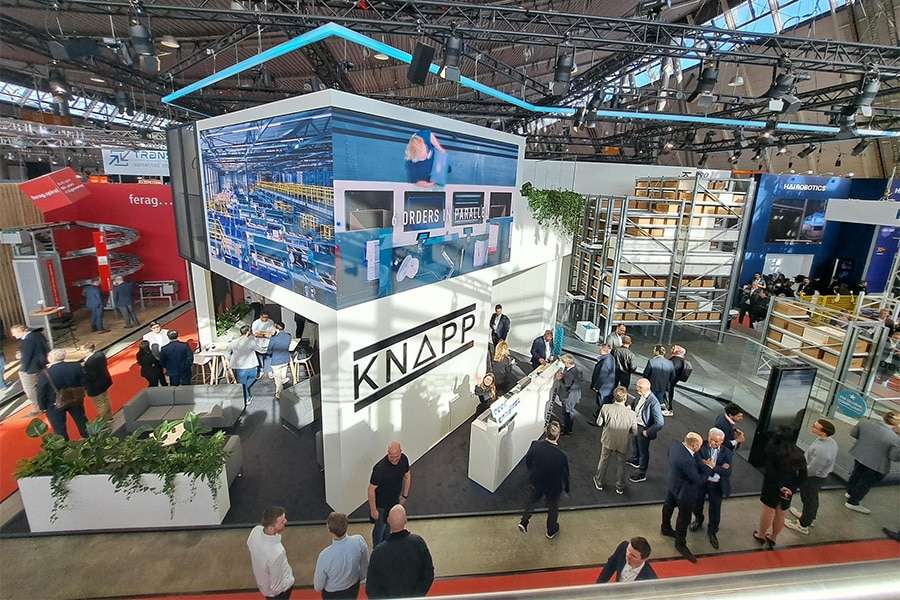

KNAPP also capitalized on this with a robust SAP EWM offering, separate from their existing hardware solutions. "We are an official SAP Business Partner and now also offer this service standalone. That caught the eye of the numerous visitors," Silvia Christensen says. KNAPP thus emphatically positions itself as a total supplier. The coveted 'Best Product Award' went to the Aerobot, the new 3D storage and buffering system with which KNAPP fills a blank in its portfolio - and immediately caught the eye.

But what about financing ...?

As the only leasing company in halls 1 to 7, DLL engaged with companies at LogiMAT about an often overlooked but crucial link: financing. "We offer customized solutions for automation projects, including advance payments to suppliers," says Guido Guiking. "This way, customers avoid cash-out during the construction phase." DLL's deep knowledge of both sector and assets makes them a unique player. "We had strong discussions and are already planning follow-up appointments. The fair was above expectations."

More than visibility: LogiMAT as a strategic platform

What remained after three days of the fair was a sense of direction. Not only in the innovations themselves, but also in the way companies were marketing their offerings. Whether it was security, scalability or software vendors anticipating disruption, everyone spoke the same language. That of concrete solutions and strategic partnerships.

Moreover, it was striking how purposeful many visitors were. Gone are the days of the casual trade show stroll. Exhibitors reported visitors who had looked up the right info in advance, prepared questions sharply and talked to the right people right away. That translated into leads that were more concrete than ever.

LogiMAT reaffirmed its position as Europe's top trade fair for intralogistics and supply chain management. Not the biggest to be the biggest, but the smartest in focus. The next edition already promises a lot.