INPIEQ continues to innovate and develop new products!

INPIEQ, specialist in foundation machines and related equipment, produces, among other things, the innovative DLS Registration System which is used at home and abroad. Now they are launching a whole new production line of compact machines.

"INPIEQ is developing a new production line consisting of two different compact machines. These are a grout mixing and pumping unit type IGP and a hydraulic foundation machine. With the important aim of being user-friendly and easy to maintain." Says INPIEQ director Frank van Deursen.

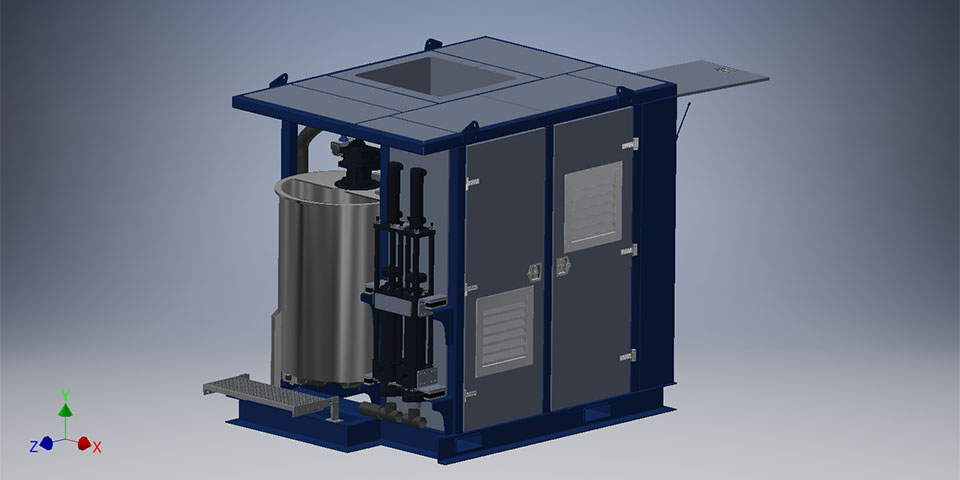

Compact fully automatic grout mixing and pumping unit

This all-electric hydraulic grout mixing and pumping unit type IGP is electrically driven. Equipped with a mixing unit which automatically mixes the mixture and then moves it to the reservoir until it can be pumped to the drilling rig. This machine is equipped with pressure and flow controllers. As a result, the pumped pressure never exceeds the preset value and the machine has the maximum flow and pumping speed. During this process, data such as cement water consumption, pump flow, working pressure, pumped volume are measured high accuracy, clearly shown on the display and stored in the INPIEQ Registration System. This data is transmitted to the office via USB or wirelessly. The unit can be operated via the clear control panel and controlled via remote control. Frank: "We saw room for improvement in existing similar machines and possibilities in combination with our unique INPIEQ Registration System so we started building it ourselves. This resulted in this compact machine which gives the highest achievable result with a constant flow without peaks and registers all data directly."

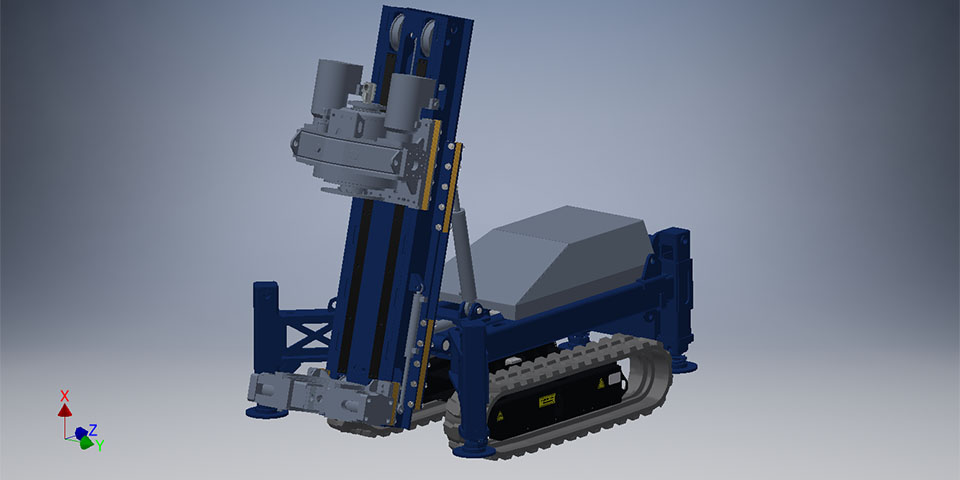

Compact hydraulic foundation machine

A compact, lightweight but very powerful machine which makes it possible to manufacture screw injection piles in places where space and height are limited. The foundation machine is equipped with a drilling motor of up to 20 kNm. The size and weight makes the machine easy to transport and its unique construction also makes it possible to work in different spaces.

This machine comes with an electric power pack on tracks which is equipped with 2 electric motors making it possible to drive the machine with both a 32A and a 63A connector. Furthermore, it is possible to drive the machine via a specially developed battery powered hydraulic unit.

User-friendly

Frank: "The customer knows where to find us when it comes to innovations and personalization of machines and/or systems. We then use our expertise and experience to come up with a solution that meets the customer's requirements. This time we were asked whether it was possible to develop machines that are easy to transport.

Custom

INPIEQ more often develops and produces innovative machines from its own initiative or on request. Almost every machine involves a piece of customization. This all happens in-house from the workshop in Steenbergen. Another machine which was recently made on request for a client in Belgium, is a CPE30 piling hammer for piling sheet piles with a special sheet-leg frame. The low hydraulic power required makes this hammer easy to use in combination with a mobile excavator.

DLS Registration System

INPIEQ produces the world-renowned Data Registration System which they designed themselves. Frank: "The DLS Registration System is suitable for piling, drilling, vibrating and pressing and records the data of every pile made - regardless of type. Then, if required, the system sends the data to the office. This summer a new version of the registration system will be released that will meet today's requirements in the foundation market. Also a new platform will be introduced to process the data faster and easier. Also the cooperation with a foundation expert bureau offers great added value to the system so that the foundation company, before leaving the construction site, knows that all the piles have been approved for delivery.

We proudly sell this product tailored to customer needs around the world."