Hydrogen blending can sharply reduce emissions

Are we going for diesel or hydrogen? At machinery distribution and service specialist Luyckx, they didn't want to choose hard this time, but in consultation with CMB.TECH, a first dual fuel excavator was realized. As a Hitachi dealer, Luyckx chose to convert a 37-ton ZX350LC-7. It runs on diesel with hydrogen admixture. This can reduce CO2 emissions by half.

Prominently displayed at Luyckx's MATEXPO booth, the converted Hitachi ZX350LC-7 won third prize at the Green Awards. Rightly so. Because hydrogen blending is serious news for our industry. It has been used in small shipbuilding for some time and that is why Luyckx has joined forces with CMB.TECH. This Antwerp subsidiary of the shipping company Compagnie Maritime Belge presents itself as an active developer and integrator of hydrogen solutions with a focus on engineering, hydrogen production, industry and marine applications. The modified Hitachi ZX350LC-7 now accelerates gradual greening within the heavy construction and earthmoving sector. With this, dual fuel offers companies the opportunity to make substantial progress in the energy transition affordably with current machinery, without being permanently dependent on the availability of hydrogen, the story goes.

From challenge to vision

For Jos Luyckx, the CEO of the Brecht-based company, it's a clear story: "Driven by the wishes of our end users and fleet owners, we started a feasibility study on our own initiative into possible alternative solutions that would help reduce CO2 emissions, make the fleet of machines more sustainable and corporate social responsibility. We have been looking for the right solutions for this for several years. The challenge was mainly in the energy requirements of heavy machinery. From that vision, the cooperation with CMB.TECH was started."

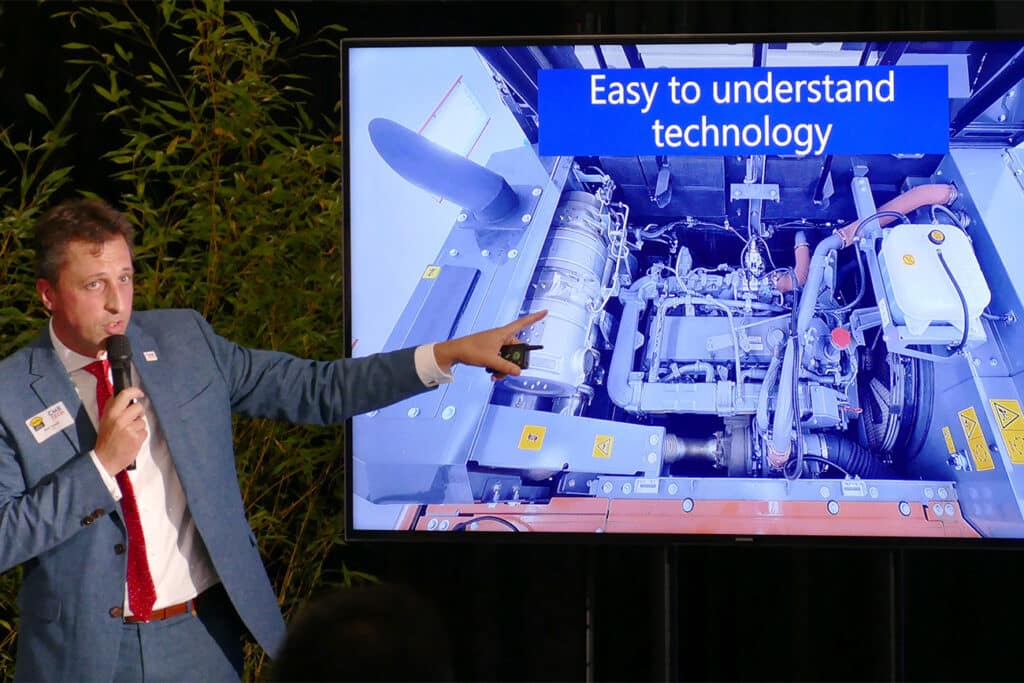

In converting to dual fuel, little was changed to the Isuzu engine, so maintenance can also be performed in a virtually regular manner. The excavator starts up with diesel and only when the engine is up to temperature is hydrogen added. That comes from the tanks that are stacked prominently behind the cab.

Affordable solution

Fully electric drives are still quite expensive and, with the current state of the art, not suitable for the really heavy equipment. Opting solely for electric drives may therefore currently hinder the energy transition more than promote it, so an interim solution is more obvious. From this point of view, the use of dual fuel technology is quite justifiable at the moment.

Roy Campe, technical director at CMB.TECH, tells it his way: "The additional cost of the machines in the sector is rather limited, where the kgs of hydrogen used immediately lead to CO2 reduction. From now on, we offer the applications to enable without operational constraints and for the lowest possible cost up to 8 tons of CO2 reduction per site per day, anywhere in the Benelux."

Mobile hydrogen refueling station

Since hydrogen supply is another major bottleneck, CMB.TECH presented a mobile hydrogen refueling station in addition to the dual fuel excavator. This is built on a closed trailer and can thus bring up to 600 kg of green hydrogen (at a pressure of 350 bar) to the machine anywhere a truck can drive. This works not only for (excavating) machines, but also for trucks, generator sets and the like. Roy calls the mobile filling station, "The answer to hydrogen supply in maritime and industrial applications."