Higher excavator efficiency

Thanks to SQ fully automatic quick-change systems and tiltrotators for infra and demolition

As the world's fastest growing manufacturer of tiltrotators and quick couplers, Swedish company Steelwrist AB offers various equipment that makes excavators more versatile, precise and profitable.

Tom van Baars, country manager Benelux at Steelwrist notices that the GWW, demolition and civil engineering market is in a state of flux. "A certain job requires an equipment and that equipment requires an excavator. Not the other way around. And exactly that is our starting point in increasing excavator efficiency." Steelwrist develops, manufactures and sells tiltrotators, quick couplers, accessories and attachments for excavators and backhoe loaders.

Tiltrotator

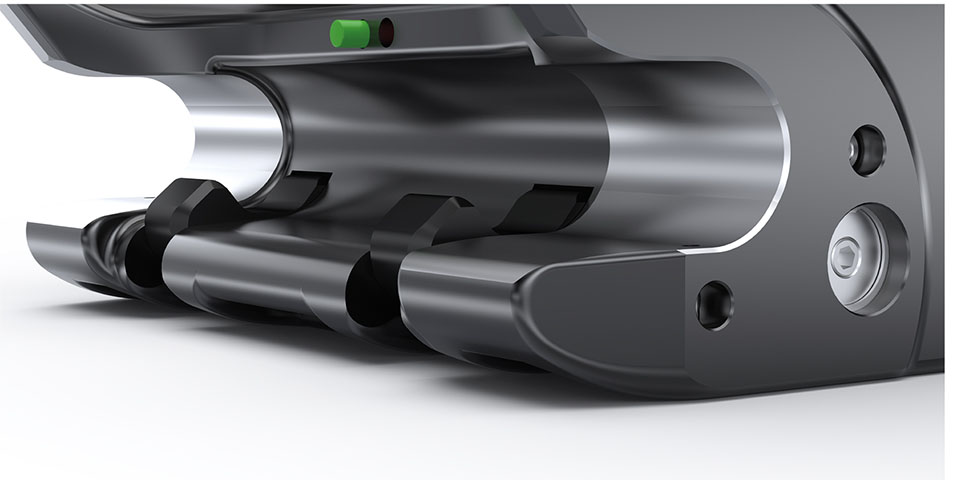

"The more complicated the job, the higher the productivity is when a tiltrotator is used," says Van Baars. The Steelwrist tiltrotators have a low build height, a large tilt angle and a unique power-to-weight ratio thanks to the cast steel parts. "It is the most compact and optimized tiltrotator on the market. But when changing attachments frequently, a quick-change system is a must."

Fully automatic quick-change systems

"Our SQ technology turns quick couplers and tiltrotators into fully automatic couplers of hydraulic and electrical connections that are directly established in one motion. The operator does not have to leave the cab to change attachments. Beautiful, isn't it? That's how an excavator becomes a true tool carrier and we can live up to speed and efficiency." Steelwrist's SQ quick coupler is perfectly compatible with the (symmetrical) standard prevailing in the market. In practice, Van Baars sees that customers, who previously worked with separate excavators for demolition and infra, now combine them. "This makes the machinery versatile."

Thanks to Front Pin Technology on our SQ switches, we have managed to maintain the high level of safety without having to use complicated and expensive systems with sensors and the like. This makes it suitable for all control systems, whether the excavator is small, large, new or used.

Increased safety for all excavators with the symmetrical quick couplers with Front Pin Lock

Laws and regulations surrounding safety issues are constantly being tightened. "A good thing," Van Baars believes. "As a result, customers are increasingly asking for safer quick-change solutions. With the patented Front Pin Lock technology, we realize increased safety for all excavators." Van Baars explains: "Thanks to the Front Pin Lock, the operator can clearly see from the green indicatior when the bucket is in a safe position. Thanks to FPL technology -which operates independently of sensors or electronics- and internal return springs and safety valves, the quick coupler complies with ISO13031 and the highest safety requirements in all markets.

In conclusion, Van Baars says, "Machine efficiency is number one for us. Interchangeability is hugely important in this regard. That is why we have even entered into collaborations with our competitors. This is how we open up the market and the machine efficiency and thus the benefit to the end user becomes enormous."