From sideshow to warehouse operating system

The warehousing reality in Benelux is changing rapidly: margins are under pressure, delivery windows are getting shorter and disruptions remain unpredictable. By 2026, data is shifting from “report-catch” to the operating system of the operation. Companies that use data intelligently will steer not only on KPIs, but on real P&L impact: less inventory pressure, higher throughput and lower failure costs.

Successful digitization does not start with AI, but with basic hygiene: unambiguous item and location data, clear process definitions and a single source of truth. Standards (think uniform bar codes and data fields) and well-established master data enable integration between WMS, TMS, e-commerce platform and finance. Add event streaming (real-time events such as inbound, pick start, tailgate close) and you have a data layer that reflects the operation live.

From seeing to driving: real-time visibility

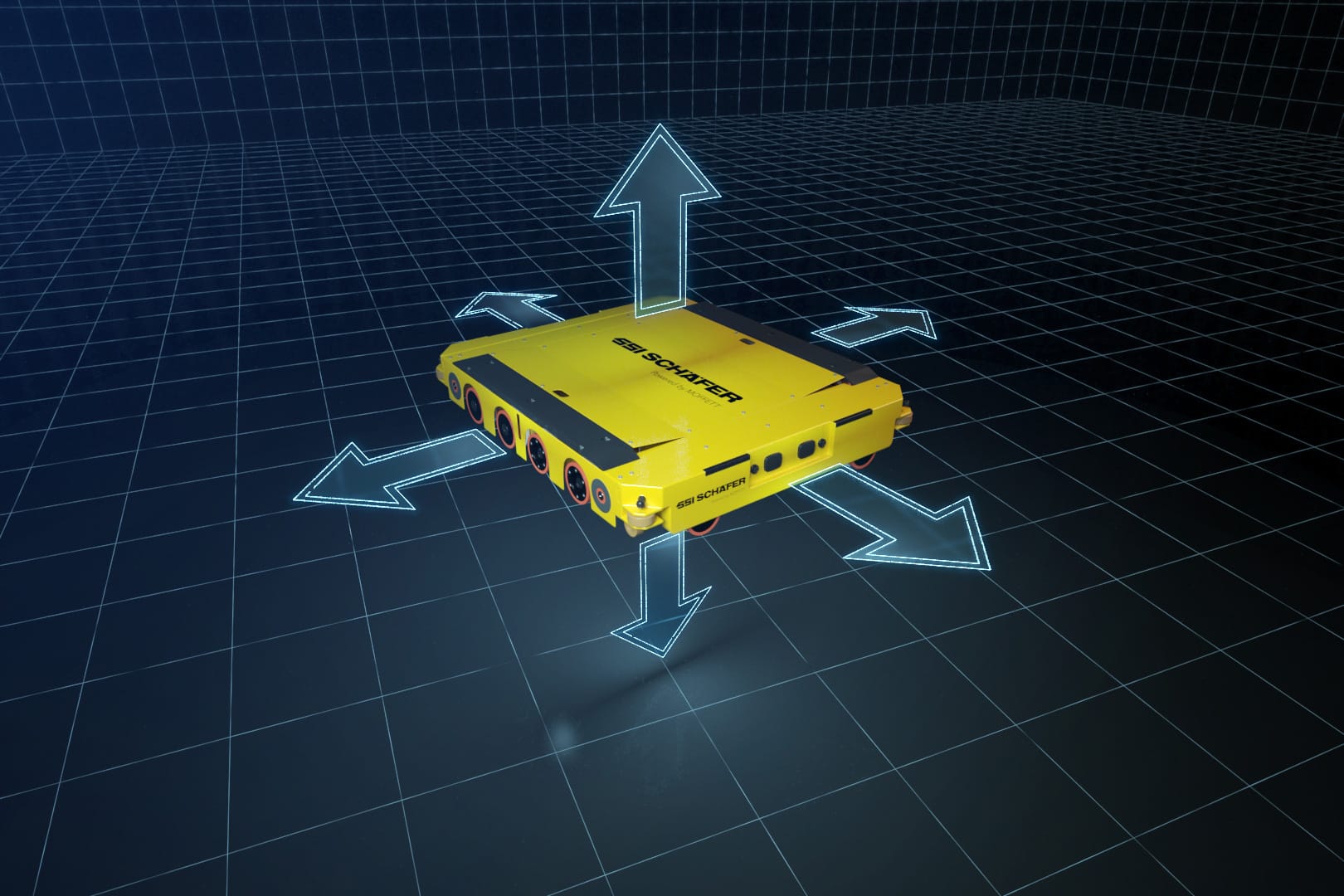

Sensors, scanners and telematics create end-to-end visibility: where is the pallet, how long does a trailer wait, what is picking productivity doing per zone? The traditional daily report becomes an operational control tower with alerts and “next best action.” Not just describing what happened, but predicting what will tie up in two hours - and proactively rescheduling.

AI is maturing in concrete use cases:

- Demand forecasting & replenishment that incorporates seasons, promotions and weather lowers safety stock without service loss.

- Smart slotting puts fast sellers close to dispatch and dynamically adjusts to peak patterns.

- Labor scheduling predicts hourly capacity gaps and directs tasks to teams or cobots.

- Quality & safety: vision-AI recognizes damage or incorrect labels at the gate.

Important is human-in-the-loop: planners confirm or correct AI suggestions. This keeps knowledge in the team and trust grows. Many applications also run on edge equipment in the DC, keeping latency low and ensuring privacy.

Digital twins: deciding with certainty

A digital twin (the virtual copy of the DC) makes “what-if” scenarios tangible. What happens to your throughput if you add an extra sorter? How does a change in walking routes affect congestion? Energy management also benefits: simulate when you load, cool or store autonomously to avoid peak rates. Decisions become measurable rather than a battle of opinions.

Security, compliance and data trust

The more data streams, the greater the risk. Zero-trust access, encryption, segmentation of networks and periodic vendor audits are not IT side-effects but operational prerequisites. Privacy-aware designs (minimal data, pseudonymization) make collaboration with customers and partners easier AND faster approval-worthy.

Digitization fails not because of technology, but because of change. Three roles become central: the product owner operations (connection between floor and IT), the data engineer (reliable pipelines) and the data translator (translates business questions into algorithms and back). Combine this with targeted upskilling: from order picker to system operator, from planner to orchestrator.

Roadmap for 2026

Start small, scale fast.

- Choose one value stream (e.g., inbound-to-putaway) and instrument it completely with events and dashboards.

- Implement one AI use case with clear euro KPI (e.g. 10% fewer emergency trips via better dock scheduling).

- Secure governance: data quality owners, security checks and a rhythm of weekly improvements.

Conclusion: In 2026, data is no longer a reporting product, but the backbone of agile logistics. Those who lay the data layer solidly, deploy AI in a targeted way and include people will transform the warehouse from a cost to a competitive advantage.