Engcon invests 8.7 million euros in production machinery - and triples production capacity

Engcon, the world market leader in turntables, will invest 8.7 million euros in new advanced CNC machines over the next three years. These new machines will allow engcon to produce 22,000 turntables per year, a tripling from today.

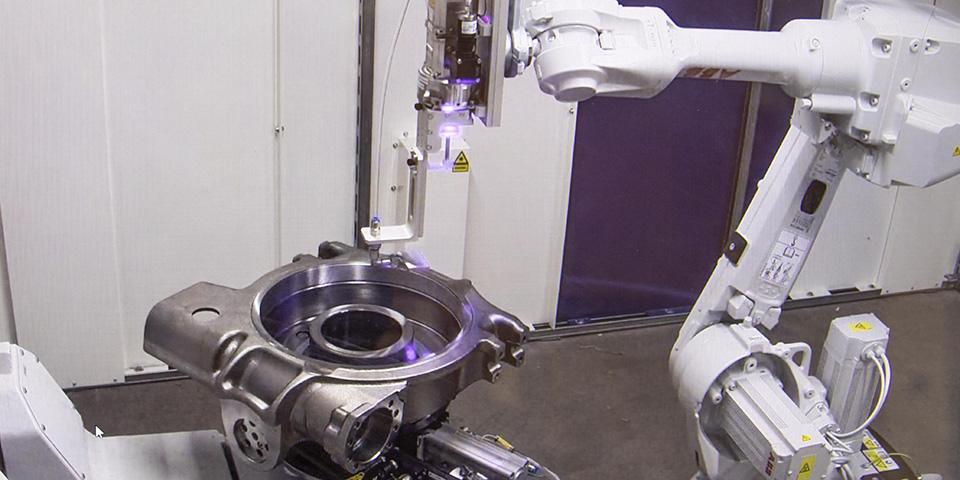

Engcon continues to grow exponentially, and to meet growing market demand, the company is committed to increasing production. Engcon is investing in new CNC machines and more production capacity. A data-driven and fully robotized production facility is going to help engcon meet the high demand.

"The new machines will be used to machine the cast frame pieces in our rotary tilt pieces. Thanks to this investment, we can achieve major efficiency improvements and triple our production capacity. This gives us further advantages over our competitors," says Krister Blomgren, Engcon Group's managing director.

Previously, some of the CNC work was performed by multiple suppliers, spread across several locations. The new machines in which Engcon is now investing are supplied and managed by the local company Strömsunds Kvalitetslego. This makes it easier for Engcon to control the production chain.

"From a production perspective, we now get a better view of the progress of our production. By centralizing the knowledge in Strömsund, we also secure expertise. In the long run, primary production will be centralized here, so we are investing in the best technology," says Krister Blomgren.

The plant was inaugurated on March 19.