Creative with (waste) water

Tightened environmental requirements, the sometimes limited availability of water and the need to look at technologies such as water reuse, means that Logisticon Water Treatment's mobile and modular water treatment plants can be found in more and more sectors. Even in the infrastructure sector, the installations are proving their added value. Indeed, that's where it all started thirty years ago.

According to Business Developer Pieter van Staveren, Logisticon is the inventor of modular and mobile wastewater treatment plants. "Our mobile and modular installations are traditionally used in excavations and soil remediation. In many cases, the released groundwater may not be discharged directly to surface water due to the presence of soil-borne substances. These substances are filtered out of the water by our installations, so that it can then be discharged. In this way, we made an important contribution to the construction of the metro system in Utrecht, for example, where groundwater with a capacity of 300 m3/hour was purged."

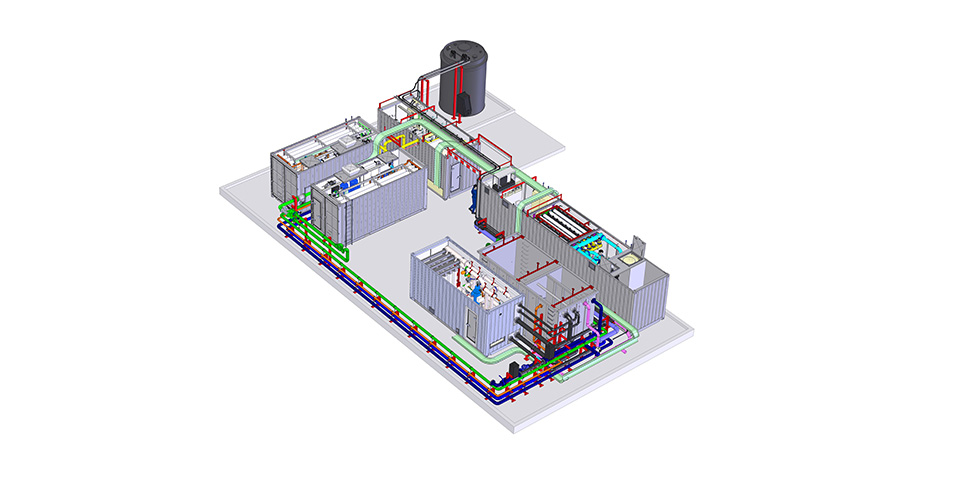

Modular membrane bioreactor (MBR) plant.

Availability

Industry is also increasingly benefiting from modular and mobile installations, says Van Staveren. "As a result of tightened environmental requirements and growth or shrinkage of certain markets, utilities are also subject to change. With our modular installations for process, drinking and wastewater, we always offer the right solution, as we have demonstrated over the past thirty years anyway. We also see that the availability of water is no longer always a matter of course, for example as a result of dehydration. Especially when water boards impose that no surface or groundwater may be abstracted for a certain period of time. Finally, European and national legislation requires companies to demonstrate what substances are in wastewater and how they are treated. Also in case of calamities."

Smink membrane bioreactor (MBR) plant.

License to operate

Logisticon has proven that it can respond quickly in the event of a calamity. Van Staveren: "Sometimes we can set up treatment plants within 24 hours so as not to jeopardize a company's 'license to operate'. We also provide relief in the event of calamities. During the Chemiepack fire in Moerdijk, for example, we placed treatment plants in record time to prevent further environmental pollution."

Treatment of process water at Vynova in Geleen.

Win-win

Discharging wastewater is often still seen as the most economical solution. "That is by no means always the case after all," Van Staveren knows from experience. "Thus, we can demonstrate that companies can realize considerable savings by reusing (waste) water. For one thing, they pay less discharge costs, meet the latest environmental requirements and also have to take in less drinking or surface water. By examining processes properly and in a smart and creative way, you could, for example, capture the water halfway through a process and reuse it elsewhere in another process. A win-win."

Techniques

In addition to applying traditional techniques, Logisticon also relies on membrane technology for several decades. "Together with membrane suppliers, technology providers and our customers, we have done a lot of research on this technology. We have been able to continuously refine it to achieve broad applicability, savings in the use of chemicals, energy, etc. The beauty of our installations is that we can adapt them, specific to the situation. That way we can also respond very quickly to a changed demand or emergency situation. Although our installations are often mobile and modular, in many cases (especially in industry) they have a permanent setup," Van Staveren concludes.