Successfully increase E-commerce capacity

E-commerce continues to grow and every distribution company naturally wants to respond well to that. "We take a holistic approach to logistics issues and, together with the customer, we lay out a customer journey that leads to a future-proof solution that suits the company and the volatility of the market. In doing so, we don't put the means but the solution first," says Rinus Geurts, Business Development Manager at Inther Group.

"Anyone who wants to move with the growing e-commerce market as a company must properly align their distribution center with demand. In a physical store, there is a very different flow of goods than in e-commerce. Not only are there high peaks due to Black Friday, Christmas and Easter, but the online buying behavior of end consumers fluctuates greatly, due to the weather, the season or whatever happens to be trending. It is important for e-commerce companies to move with the whims of the market, both in terms of assortment and system technology." Speaking is Rinus Geurts. He has been responsible for business development at Inther Group since 2024. As a hybrid system integrator, the Venray-Oostrum-based company specializes in automation solutions for picking, packing, storing and sorting goods in warehouses worldwide. It assists customers throughout the entire technical life cycle of the system, analyzing, adjusting and optimizing where necessary. For example, it has now completed successful projects at various e-commerce (and other) companies worldwide, including Picnic, CoolBlue, Obelink, Zeeman and HEMA.

Orders, flow and growth expectations

Geurts: "If you want to take your E-commerce to the next level, it is necessary to map your online orders, flow and growth expectations. Based on a dataset - through the WMS - we determine together with the customer improvement steps for the future. In doing so, we make an analysis of the items they sell so that we can define within which handling unit they fall and which picking strategies might be interesting for efficient order processing."

Smart software

The secret to an optimized distribution center lies in choosing quality systems as well as smart software for optimal workload distribution, Geurts continues. "Inther offers customers not only an automation path, but also smart software and a bit of data science so that in a high performance warehouse, all variables can be taken into account - with both fast and slow runners, high peaks, large and small orders, but also the pick order. After all, you don't want your ordered laundry detergent to be picked on your chips. Thanks to real-time and historical information, we can provide a complete picture of the warehouse at any time and know in advance the impact of orders on the workload in the different zones. With adjustments to the software, we also make improvements over time to achieve, for example, shorter lead times without having to add hardware directly. That, of course, is much faster, easier and cheaper. Compare it to a car, which is tuned instead of having engine parts

be replaced."

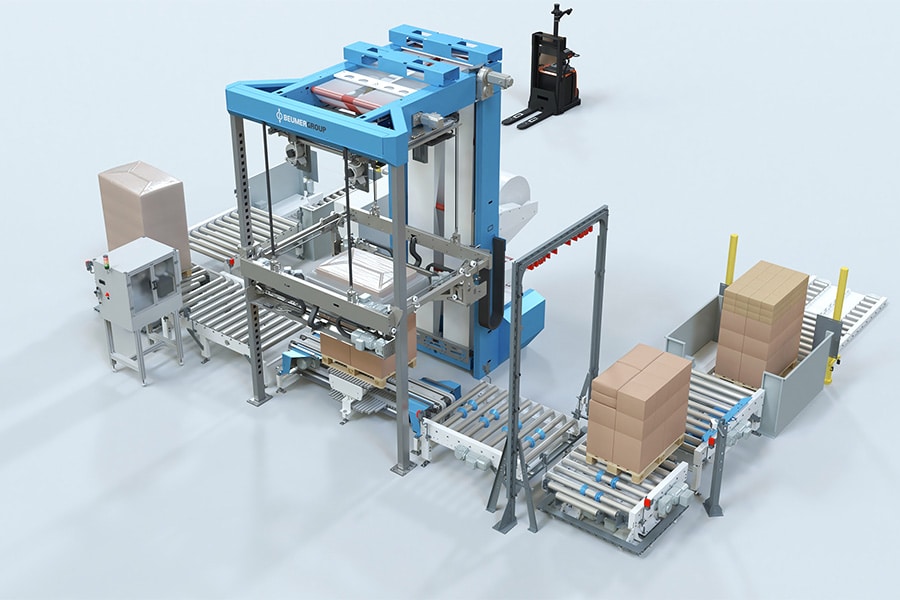

Inther is hardware-independent. "When new hardware is needed, we always choose the hardware that best suits the customer's sales flow and type of products." One such large e-commerce customer is HEMA. "At HEMA, we made sure that the automation system could handle both the constant flow of goods/products but also handle the workload during peak periods. A hybrid solution was chosen that includes automated order picking machines with a miniload system with space for 13,000 plastic totes, two miniload cranes that can place the required totes on a roller conveyor that transports them towards the shelf locations, a shuttle system with 75 shuttles that have space for 33,000 plastic totes, multiple order picking stations and order picking carts with pick-to-light technology, box erectors, label applicators, Automated Document Inserters, conveyors and so on." It wasn't built that way right at the start. It has grown that way over the years, optimized and adapted to the changing flow of goods at HEMA.

Innovate

Inther Group continues to innovate constantly. For example, it recently successfully completed an e-commerce project in which it opted for a unique combination of various intralogistics technologies such as AMRs (Automated Mobile Robots), Autobaggers and an A-Frame, a fully automated solution for the rapid processing of complex orders guaranteeing the highest possible productivity and optimal material flow, even at peak load. Thanks to continuous stock monitoring, real-time video registration and product heat mapping, orders are processed 100% correctly. Geurts: "We realized this unique combination for QuickBox Fulfillment in Atlanta (US), a 3PL company that processes online orders from end consumers for refills for Pura fragrance diffusers. Even before Black Friday, the absolute peak season for the distribution center, the company was able to benefit from a completely automated system."

Prime

Systems integration is the key to the success of this first. "This particular hybrid integration of different types of intralogistics technologies has not been deployed like this before anywhere in the world. The Inther A-frame with dual filling station drops the products onto the AMRs. These then distribute most of the orders to about four Autobag packaging machines, after which sorting takes place. About 70% of the orders are picked, packed and sorted fully automatically. The remaining percentage - mainly the slowmovers with sizes too large to fit in the A-Frame - company employees pack manually via an Inther pick-by-light system. All QuickBox has to focus on is refilling the A-Frame. The rest of the process is completely automatic."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Inther Group B.V..

Contact opnemen

Contact opnemen