'Scenario thinking is essential when scaling warehouse automation'

Logistics operations continue to grow, albeit more often incrementally than with a big bang. "Regardless of the situation, the certainty to scale up is important. When scaling up warehouse automation solutions, scenario thinking is the key to success," says Machiel van den Hazelkamp, CCO at integrator Lalesse Logistics Solutions, part of Reesink Logistic Solutions.

The world is turning, many logistics operations are growing with it, despite geopolitical turmoil, inflation and economic uncertainties. Van den Hazelkamp: "That logistics growth continues is very good, but companies are more cautious. So it's more important than ever to make sure you can scale up as a company."

Modular solutions are a good tool to secure that scalability, according to Van den Hazelkamp. "Of course, those must deliver immediate value and pave the way for future-proof growth." As a neutral integrator, Lalesse has made its specialty of providing all kinds of automation solutions and integrating them seamlessly.

'Bringing customers into scenario thinking'

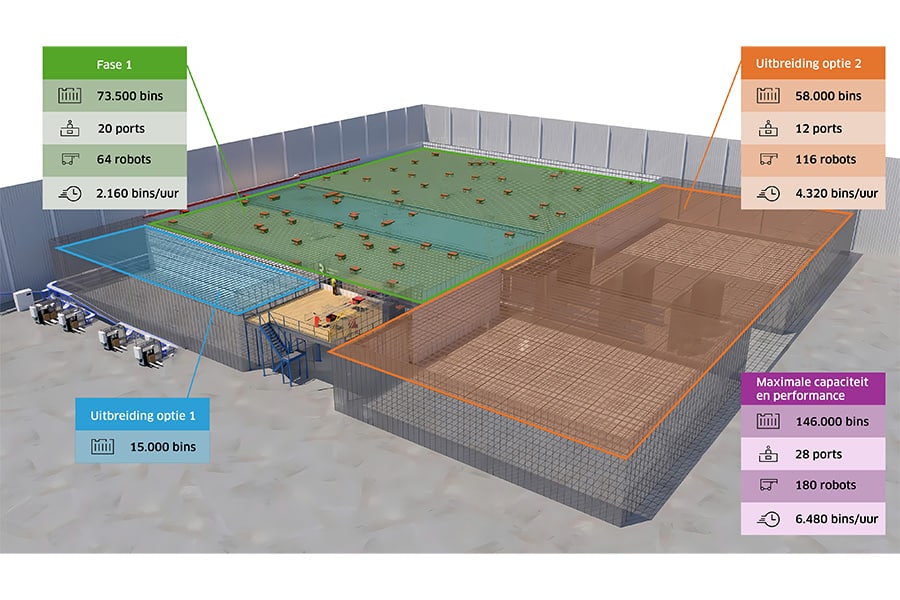

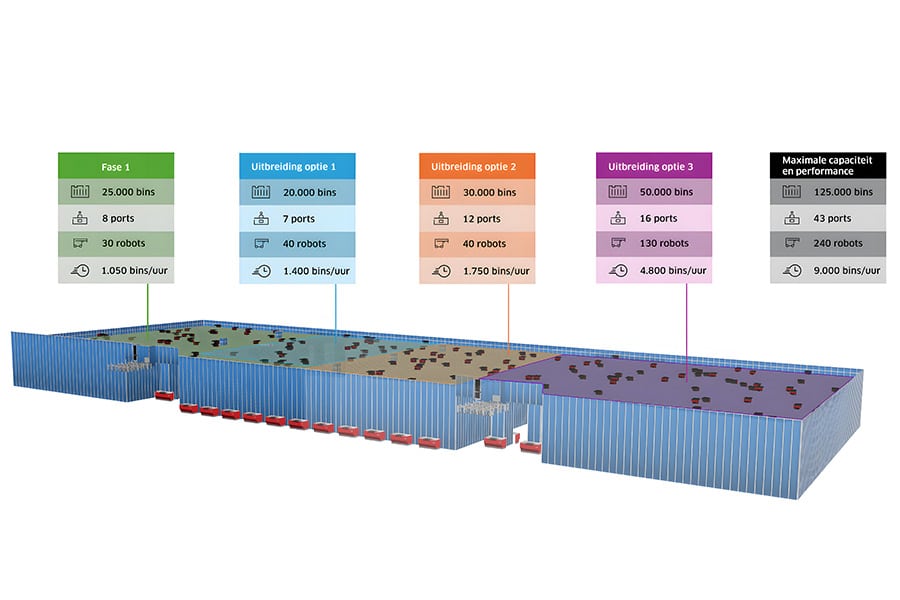

Logistics companies and shippers with their own storage knock on Lalesse's door for advice, including on scalability. Van den Hazelkamp: "What we do a lot in that case is take customers into scenario thinking. If scalability and flexibility are important, there are various scenarios that can lead to the desired situation. The expected situation for next year and the year after are decisive, but in all cases you have to consider long-term growth. All these scenarios create a good picture of the direction and available options. Then the entrepreneur also knows to what extent automation can support in scaling up."

AutoStore is easy to expand

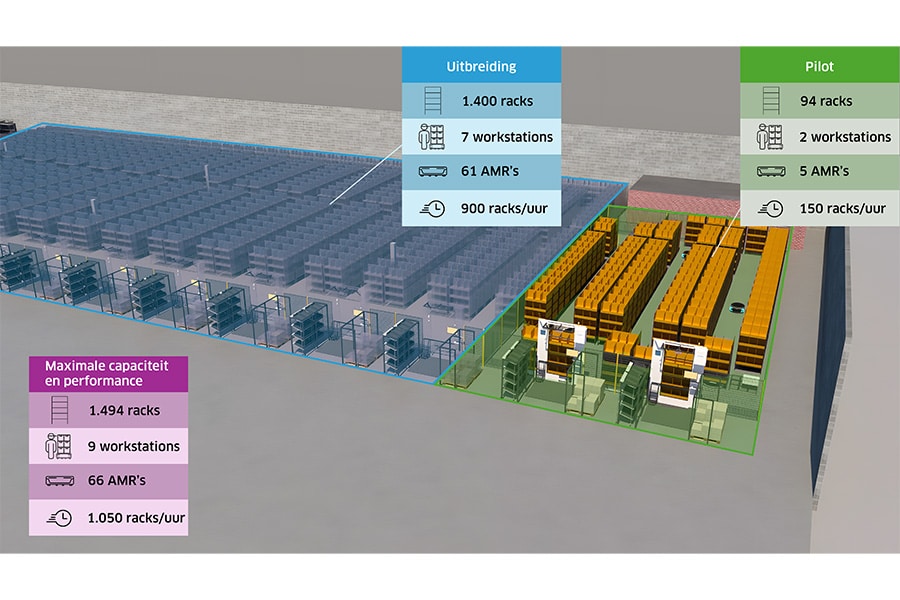

An AutoStore system is a good example of an automation solution that is expandable. "With that system, the flexibility of a logistics operation is maximized. An ROI of 24 months is regularly achievable in this regard. That also enables a user to take follow-up steps from business growth and cash flow." According to the CCO, what makes an AutoStore convenient is the ability to expand storage or picking capacity by adding more totes, robots or workstations without causing operational disruption

"What makes an AutoStore system unique is the enormous storage density, often requiring only 25 percent of normal warehouse space." That creates room for further growth opportunities. "In an existing operation, space often seems a given, but with smart automation we actually create new opportunities. Extra capacity where it is needed most, to optimize processes and effortlessly support organizational growth.

Conveyor, AMR or pick robot as an addition

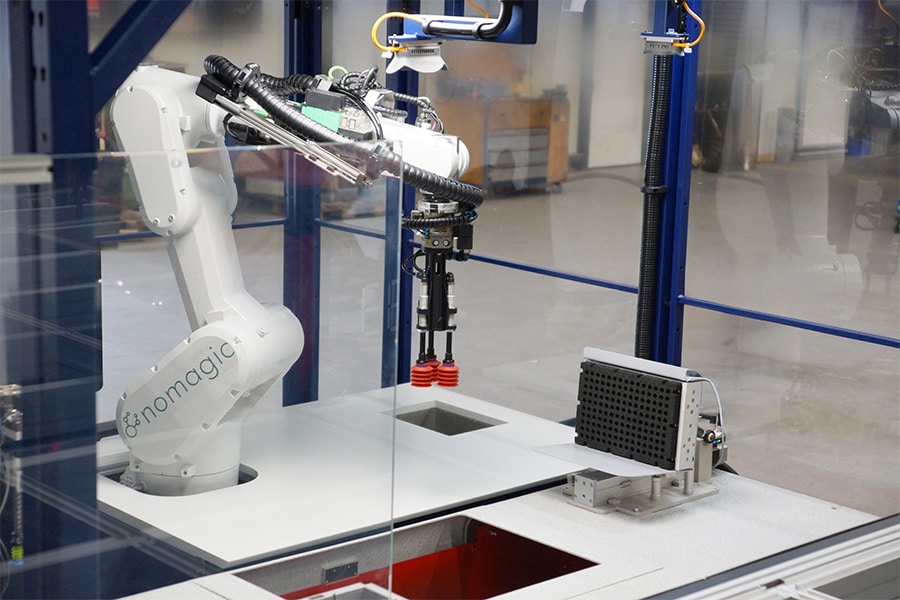

When looking to scale up automated warehouse automation, there are plenty of options besides additional storage options and capacity and packing machines. Van den Hazelkamp lists a few: "A conveyor or AMR system can make the infeed and outfeed of totes around a storage system more efficient. Weight control can also be added or product scans. More and more companies want to add a positive barcode scan when picking, as an additional process and product confirmation. Some of our customers have added a pick robot retrospectively to the AutoStore installation, which can replace an operator 24/7. If this works well, more pick robots will follow at the other workstations."

Software, cameras and AI

With a powerful Warehouse Control System (WCS), controlling all scaling options is no longer a problem. Not even if they come from various suppliers. "Our in-house developed LogiCS WCS seamlessly links the various subsystems and products together and forges them into one integral working solution. In the process, the possibilities are only increasing. Adding camera systems and AI to processes creates even more control, efficiency and process optimization opportunities."

'Automation is obvious choice'

Van den Hazelkamp expects the growth in adoption of warehouse automation solutions to continue in the coming years. "Mainly because it makes operations more flexible. In doing so, there is still a stretch in the penetration rate. There are more and more options to support logistics processes that now mainly rely on manual activities with automation. With the tight labor market, automation is the obvious choice."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Lalesse Logistic Solutions.

Contact opnemen

Contact opnemen