KNAPP Benelux: leading new software for smart warehousing

In the world of warehouse logistics, KNAPP Benelux is often associated with advanced hardware solutions, such as shuttles, AMRs and robots. But behind these technologies lies an often underestimated power: intelligent software. In a time where supply chains are becoming increasingly complex and flexibility is crucial, software forms the backbone of efficient logistics processes. Werner De Swaef, Sales Director, and Paul Pouwels, Senior Consultant Digital Solutions, explain how KNAPP Benelux plays a prominent role in this.

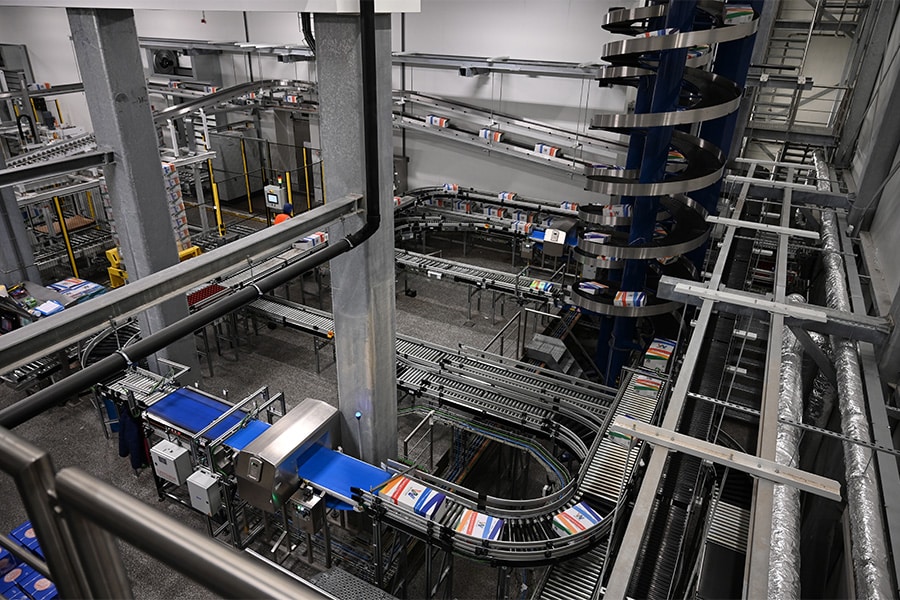

A one-stop shop for automation and digitization solutions. That's how you can briefly and concisely describe KNAPP. "Companies can come to us for a wide range of applications," says Werner De Swaef. "Our offering includes shuttle systems, digital solutions and AI, AMRs, pocket sorter systems and order picking robots. Worldwide, as a system integrator, we have implemented over two thousand intelligent automation solutions in various sectors. With fleet control software and digital twins, among others, we help companies achieve efficient warehouse management from start to finish."

KNAPP Benelux.

From supplier to strategic partner

"At KNAPP, we adopt the philosophy of a 'Value Chain Tech Partner,'" explains De Swaef. "We are not just a technology supplier, but a strategic partner that contributes to a customer's entire value chain. We help him create value for his own customers through the smart integration of software and hardware. Our solutions cover the entire logistics chain, from production to delivery. Innovation is in our DNA and we are constantly developing new solutions to optimize warehouse management. Moreover, long-term cooperation is at our core, with a strong focus on sustainable and efficient solutions."

Software as the key to success

"Although only 10 percent of costs in logistics projects go to software, this technology determines as much as 90 percent of success," Paul Pouwels emphasizes. "Without intelligent software, even the most advanced hardware solutions remain stuck in inefficient processes. That's why we developed KiSoft, a powerful software ecosystem that connects and optimizes all applications within a supply chain. KiSoft acts as the brain of the warehouse, providing both vertical integration - from machine control to warehouse management and supply chain analytics - and horizontal integration across the entire logistics chain. In this way, we guarantee maximum efficiency and flexibility."

Smart solutions to modern challenges

"The logistics sector is under pressure," states De Swaef. "Shorter delivery times, the rise of e-commerce, staff shortages and rising costs demand maximum efficiency. Our software offers innovative solutions, such as KiSoft WMS, which optimizes all warehouse processes, from goods receipt to shipping. KiSoft WCS coordinates real-time goods flows and integrates various automation systems. KiSoft Analytics turns big data into actionable insights, while redPILOT applies machine learning to optimize and adjust operations in real time."

Intuitive interaction and predictive management

"A powerful software system is only truly effective if it is also user-friendly," notes Pouwels. "That's why we developed easyUse, a design principle that enables intuitive human-machine interaction. This increases the speed and accuracy of logistics processes. We are also betting on virtual start-up techniques, such as simulation and emulation models supported by digital twins. With these, we bring a warehouse to life digitally before physical installation begins, which minimizes errors and increases implementation speed."

Artificial intelligence in logistics

"Innovations such as AI and machine learning are becoming increasingly important in our software development," De Swaef concludes. "By integrating AI into our logistics ecosystem, we not only improve warehouse performance, but also ensure that companies can respond flexibly to changing market demands. A telling example of this is the implementation of KiSoft Vision within our Zero Defect Warehouse concept. This system uses advanced image recognition to minimize errors in the logistics process, drastically reducing returns and failure costs."

Responding to dynamic requirements

KNAPP continues to pioneer hardware and software solutions that allow companies to transform their warehouses into intelligent, flexible and scalable environments that respond to dynamic market demands. Pouwels: "Our range of innovative technologies such as shuttles, robots and advanced software gives entrepreneurs the opportunity to improve their operational efficiency, reduce costs and ultimately strengthen their competitive position. The road to an automated and smart future is full of great opportunities."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met KNAPP Benelux BV.

Contact opnemen

Contact opnemen