'Higher costs soon make automation profitable'

Staff shortages affect everyone

Companies are in the midst of a perfect storm of change. At the same time, those changes present opportunities. Lalesse Logistics Solutions sees that many entrepreneurs are running into limits. Commercial director Machiel van den Hazelkamp: "As a neutral integrator, we help with advice and scalability in solutions."

What Van den Hazelkamp now sees happening in the market is that a number of frontrunners are daring to invest immediately in the latest, efficient solutions, but some entrepreneurs are still batting their heads. Both companies face the same challenges, but deal with them differently. And that's a shame, says the commercial director of Lalesse Logistic Solutions, part of Royal Reesink: "At all levels, there are ways to respond to market opportunities, a lack of personnel or the need to work more flexibly or more efficiently."

Wide variety of solutions

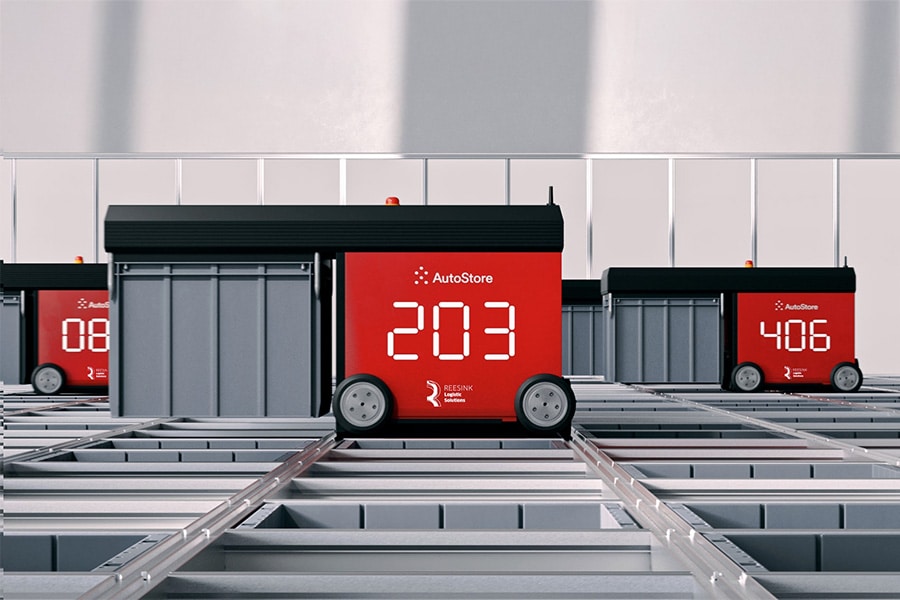

The solutions available, from rugged automated pallet storage to fully automated goods-to-person systems, cater to both small and large businesses, newcomers and established names. "As a hardware independent system integrator and consultant, we serve all of those as well. From e-commerce companies that invest directly in an Autostore system, for example, to companies that instead choose to outsource logistics to a service provider."

Playing with capex and opex

The choice of warehouse solutions is vast. Precisely that, according to the commercial director, requires giving advice. "Take an Autostore, a bin system that allows you to store goods compactly and bring them to an employee automatically. Its purchase is a significant investment. Yet even then there are choices to be made. Do you go straight for an extensive system or do you first opt for a plug-and-play 'Pio system' with the same AutoStore technology, intended for smaller warehouse environments? With that, you choose a small piece of capex and the majority in opex. Supplementary leasing arrangements are often available.

Automation gives choices

In almost all conversations with customers and potential customers, the lack of personnel is a central issue, says Van den Hazelkamp. "The increased personnel costs make an investment in automation for the warehouse interesting much more quickly. Shelf-to-person systems can bring shelves to people, making order pickers more productive." More efficiency in the warehouse can also ensure that a company can continue to operate in the same location, even as business grows.

Lower power consumption

The commercial director already touched on some of the benefits of investing in warehouse solutions, such as automation. There is one that is very topical right now. "I would like to pass that along as a tip. Power consumption is important. Choosing one automation solution or the other determines whether the connection value is higher or lower. Take pallet cranes, they have high power consumption. A pallet shuttle solution is more energy efficient. A growing group of companies are making choices based on energy consumption."

Payback period

According to Van den Hazelkamp, the high personnel costs cause more than just a stronger search for automation: "These costs also make an investment pay off faster. A payback period of one year, maximum two to three years is quite normal. That makes taking steps now extra interesting. Waiting too long is really unwise. You run the risk that the need will then be so high that you may have to move toward a big bang rollout. It is better to take a few smaller steps first and let the automation grow along with your operation. As Lalesse Logistic Solutions, we can connect everything within the operation, leaving the customer with just one point of contact."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Lalesse Logistic Solutions.

Contact opnemen

Contact opnemen