Gobotty sees many opportunities for AMR in logistics

Logistics companies should choose an AMR (autonomous mobile robot) a bit more often, Gobotty argues. By adding, for example, cobot functions to an AMR, the company wants to make entrepreneurs more flexible in their operations. Director Arie Verhoeven: "There are so many opportunities to save on labor thanks to this automation."

Gobotty was founded in 2024. Although it is a young company, it stems from two well-known companies: Dutch Machine Factory (DMF) and VMB Automation. Verhoeven: "The step we took was logical. We were already doing quite a few logistics projects. Now, with Gobotty, we fully focus on that and the client has one point of contact."

Omron and Inok

For Verhoeven, the task now is to raise the young company's profile. In doing so, he says it helps that the company is working closely with two well-known suppliers of AMRs: Omron and Innok Robotics. Gobotty uses these companies' AMRs as its "bottom end" and provides them with all kinds of build-up and control software. Thus, it provides a complete product to customers. The Omron surface-mounted vehicles are intended for indoor use, with flat floors. The Innok equipment for outdoor applications is also suitable for rough terrain. "The latter solution is what we offer as the first company in the Netherlands," he says.

'More flexibility'

"Logistics environments and production facilities are used to conventional solutions, such as the use of forklifts or EPTs. Today's need for more flexibility requires other tools. We are now bringing ideas from production to logistics. Large batches are becoming smaller and more focused on customer requirements. With an AMR, you easily transport these smaller batches of products from a roller conveyor to another production line. For example, if you produce rice cakes for forty different customers, you don't want to switch the line, you want to transport the produced cakes to another line and put the specific wrapper on them." The director says Gobotty makes difficult technology easy for users through AI.

Because Gobotty is convinced of the added value of AMRs for entrepreneurs, the company removes risk from customers by renting out the products. "With that, the Capex is 0 for the customer. Service is included in the contract. That also makes the Opex very transparent for the customer."

Replacing forklift

One of the most tangible examples of what a AMR robot can, is to replace forklifts by moving pallets automatically from a production line to a packing line. "We recently completed a project where the customer had to deploy eight fewer FTEs," he says. An additional advantage is that an AMR does not drive damage unlike forklift and EPT use.

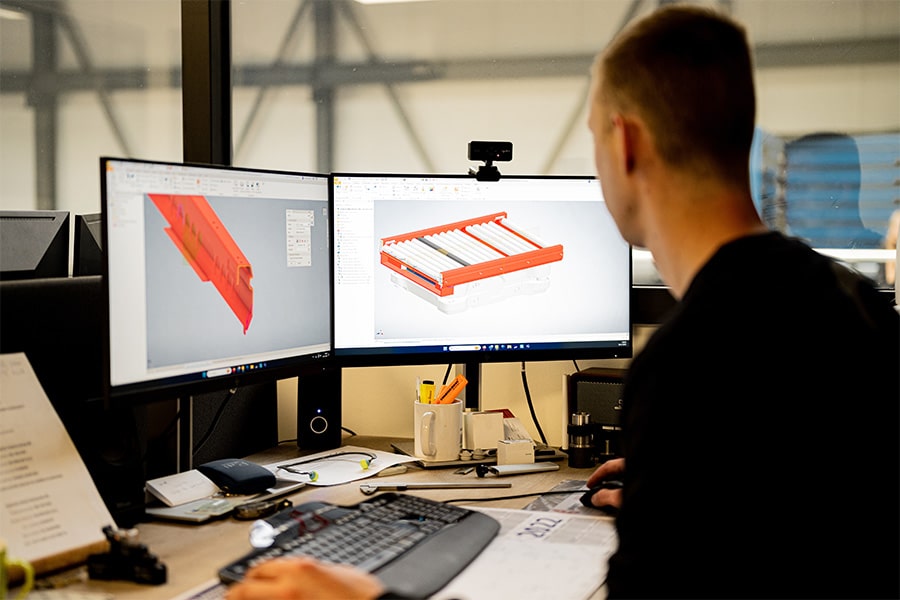

AMR equipped with robotic arm

Gobotty provides the automated moving vehicles with a standardized-or a custom solution. "Think of an addition that makes it easy to transport various types of pallets and boxes. One type of AMR can even be fitted with a conveyor belt as a topper. This allows a user to transport something on legs, for example." Verhoeven also sees some customers opting for an AMR equipped with a robotic arm. "You then deploy the AMR as a moving production line that performs certain actions while driving."

Linking with ERP and WMS

Can any company just get started with an AMR that performs very specific tasks? Verhoeven: "For certain goods movements, that is true. The fleet manager behind the AMRs can arrange a lot. The added value you can get is even greater if you can link the AMRs to an ERP, WMS or MES. system That also applies to the situation where you want to deploy more than one vehicle." An investment in an overhead system to control the logistics processes is something Verhoeven can really recommend to companies. "If you're still working on paper, you'd better eliminate that first. We're happy to help with that, by the way."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Gobotty B.V..

Contact opnemen

Contact opnemen