Experience from logistics food processes to non-food

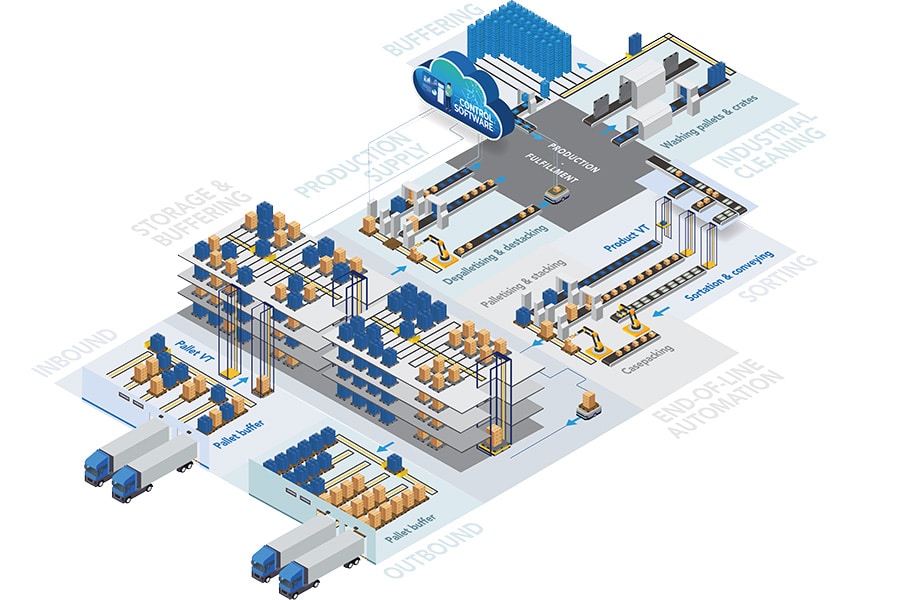

Within a smooth intralogistics organization, as many processes as possible are integrated with each other. Only then does true efficiency and room for innovation arise, says Bart Kunst, commercial director at Viscon Warehouse Automation. Viscon is both a machine manufacturer and integrator for logistics processes. “Integrating equipment and logistics tools is in our DNA. How we approach that we will show at Logistica Next.”

Viscon sees opportunities to expand market share in the intralogistics world. Based in ’s-Gravendeel, the family business has long been serving production companies in the food and agro sector. The company provides both machines and integrated warehouse solutions, complemented by smart software and logistics tools that form a complete system that seamlessly integrates processes.

Bringing together intralogistics solutions

“The number of entrepreneurs that Viscon serves is increasing rapidly. The fact that we have become an integrator is mainly because we have been working with various partners for decades to achieve an integrated solution. This includes machines, logistics automation and warehouse processes,” says the commercial director.

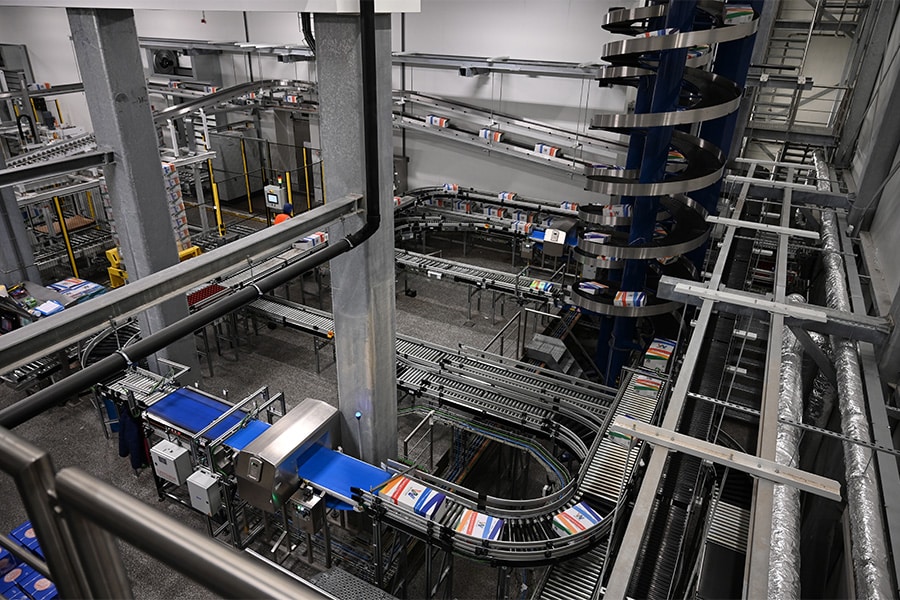

Connecting processes seamlessly

In developing its own machines, the development of the control software is also central. Art: “In addition, of course, the machine control software must connect to an automation line and, in turn, to systems such as ERP and WMS.” Because this aspect, integrating all production and logistics processes, is not well taken care of everywhere, Viscon now sees a growing demand for this. “Companies urgently need smart solutions. We help them with that integration and ensure that the flow of materials is in order. So we do that in part with our own software.”

Matrix storage system and OmniShuttle

The solutions provided by Viscon are enormously diverse. Examples include warehouse solutions with shuttle satellites, as well as the in-house developed new OmniShuttle. The latter can drive both in the main aisle and in warehouse storage channels. According to Kunst, the OmniShuttle is ideal for applications with many different SKUs and small batch sizes. “Customers like Growers United and Vergeer Cheese choose us because we provide processes with flexibility. This is important for the simple reason that the world is changing rapidly and companies need to be and remain scalable. Even if they invest in warehouse automation now.”

Widely deployable systems

Viscon now wants to use the experience from the food sector even more emphatically in the non-food sector. Art: “Regardless of the sector, the challenges remain the same for customers. Warehouse solutions with a Shuttle satellite or our OmniShuttle are forms of automation that can be used very widely.” In addition to the rise of automated warehouses, he said there is a need in the market for other intralogistics solutions. “Such as efficient transport of pallets and crates, but also the cleaning of these types of product carriers or the efficient use of mezzanine floors through pallet elevators. Our intralogistics solutions simply make the handling of pallets, crates and boxes more efficient.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Viscon Group.

Contact opnemen

Contact opnemen