'Doing more with current resources can only be done with smart choices'

More automation, more understanding data and more IT security. That's what logistics environments need. Essential here, according to Silvia Christensen-Vreuls and Werner De Swaef of Knapp Benelux, is that entrepreneurs do not over-complicate the technology and IT landscape. "Doing more with current resources and within existing spaces is only possible if you maintain insight and make smart choices."

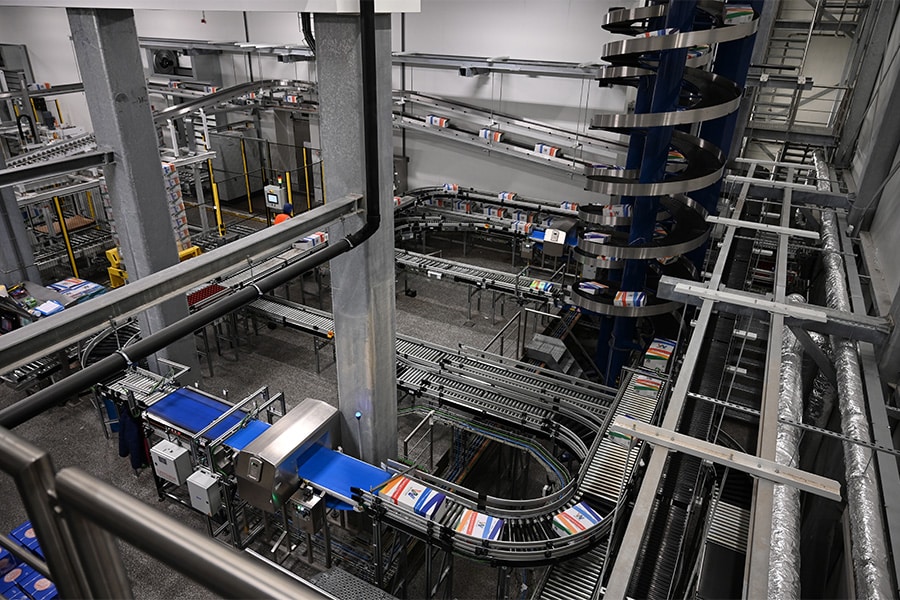

The challenges companies now face are significant, say business development manager Christensen-Vreuls and sales director De Swaef. "Many companies are growing, serving more customers, delivering more products, but want or are forced to do so from existing premises and with the same employees. That creates more demand for mechanization or automation and the challenge of handling the higher volume within the available space." At the same time, they see companies merging warehouses and facing challenges such as grid congestion.

Scaling opportunities are increasing

"Companies that want to be smarter about the opportunities that are now available, we recommend linking the digitization process with automation," the two say. Opportunities are increasing for entrepreneurs who want to scale up from an operation without digitization or mechanization to more automation. The same goes for companies that want to expand existing automation or make it more flexible. KNAPP itself provides the AeroBot system for this purpose. "This is suitable for any company, small or large. It can grow with the need and integrates seamlessly with other systems we offer, such as AMR technology. AeroBot is also a perfect complement to OSR shuttle technology."

'AeroBot offers flexibility'

What both actually want to point out with the AeroBot example is that it gives companies with logistics processes access to flexibility. "Every vendor shouts that their system is flexible, every company strives for flexible processes. The question is what you mean by flexibility. The AeroBot works on the basis of free navigation, i.e. without beacons or lines, so it is really flexible in how it moves within a storage zone. At the same time, it communicates with other KNAPP solutions."

'Improve throughput'

When tying together various logistics systems, data and digitization is the key to success, the two argue. "Those looking for more flexibility must first understand processes and where something can be improved. Good data is important, then often with limited investments the throughput can be improved." A data layer between business systems and automation and mechanization tools can also provide more insight. "We collect data from both proprietary systems and non-KNAPP environments and then analyze how processes can be improved.

Responding to new channels and flows of goods

Practical examples of companies seeking more flexibility abound. Christensen-Vreuls: "Take the healthcare sector. They used to have a wholesale approach, but are now also active online, so they work omnichannel driven and consolidate goods flows. The puzzle becomes more complex, understanding which steps a package goes through, whether a step should happen earlier or later is necessary when responding to these new flows."

Logistica 2025

At Logistica, from November 4 to 6, Knapp will show how logistics entrepreneurs can respond to market developments despite challenging times with software and automation such as the AeroBot system. De Swaef: "Whether it's individual elements that need to make a difference or integrating new tools into an existing environment, there is always a 'right' solution. We as KNAPP have a strong local presence in both the Netherlands and Belgium. Advising and integrating is really in our DNA."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met KNAPP Benelux BV.

Contact opnemen

Contact opnemen