‘The output of many a logistics system could be so much better’

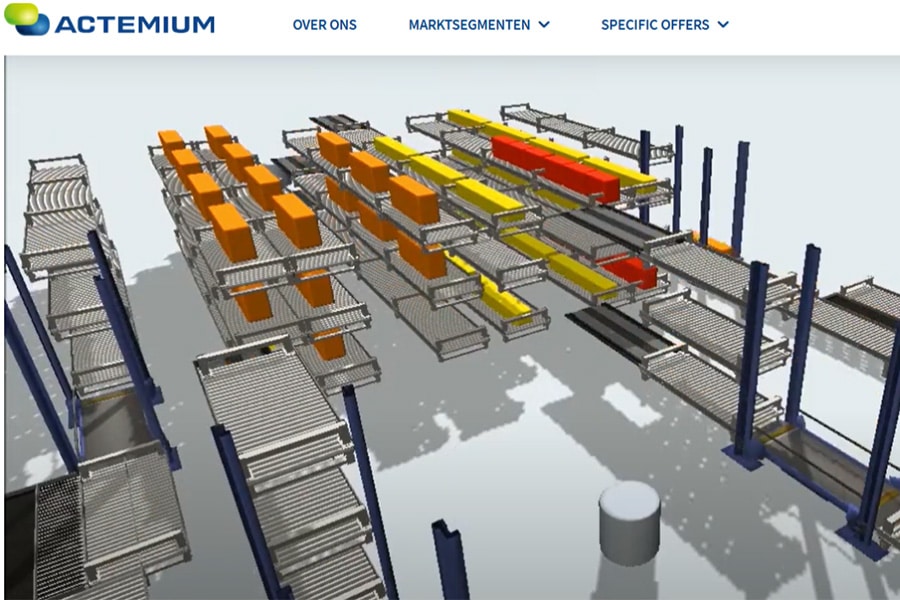

Many logistics systems are composed of various components, such as storage systems, pick stations, conveyors and sorters. The coordination between those machines and elements is not optimal in many cases, says Frank van Doesburg, client manager of logistics at integrator Actemium. “Perhaps the output of the total is only sixty of the intended one hundred percent. We help companies boost this percentage.”

The integral coordination of logistics systems is often a neglected issue, Van Doesburg argues. “Often entrepreneurs or managers don't even realize this lack of coordination and inefficiency.” Integrator Actemium provides small to medium-sized logistics systems, for both warehousing and industry. In addition, extensive knowledge and experience is available for retrofitting and modifications of existing logistics systems.

‘Changing focus in implementations’

The client logistics manager sees that many companies with logistics operations, see automation as a ‘silver bullet. ’Of course automation and mechanization offer many opportunities, but the way you approach this is all-important for success and effectiveness.“ Van Doesburg finds that many implementations now lack buffers in realized logistics systems. ”You can't just tie systems for storage, picking, packing and sorting together one on one. Individual process steps have all kinds of fluctuations due to simple disruptions or human actions, for example. Not including that aspect in design and implementation leads to an output that may only be sixty of the desired one hundred percent.“

Simulation of total image

From his role at Actemium, Van Doesburg insists on the careful design of systems, using simulations where necessary. That, incidentally, is a story that is not always easy to put across. “A supplier who may supply a system also knows that every element that is added drives up the price. That can make a business case seem less interesting. What we do is use simulations, for example, to paint a total picture. In that, we explicitly include total output as ‘overall equipment effectiveness’ (OEE).”

Boosting output

In the design phase, we look not only at the average product and average throughput, but also at deviations from the average. Based on a static or dynamic simulation, we then work toward the most optimally matched system. In doing so, the final output is more in the direction of one hundred than sixty percent. This is something that works for both existing and new logistics systems, possibly also in the form of retrofitting existing systems or modifications to them.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Actemium Logistics.

Contact opnemen

Contact opnemen