'A customer must be satisfied even after 5 years'

The adoption of robotization solutions, such as AMRs, offers companies opportunities to work more efficiently. Yet due to insufficient attention to proper integration, this certainly does not always succeed. Arie Verhoeven, director of Gobotty: "Our concern is that a customer is still satisfied with the solution even after five years."

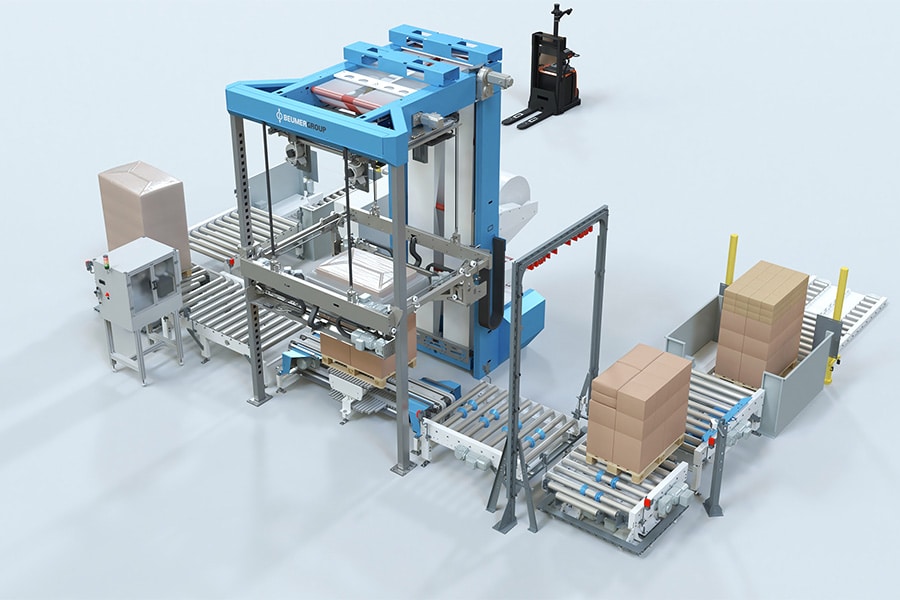

Gobotty is known in the market as a supplier of robotic systems for companies in manufacturing and logistics. The products the company supplies are based on a standardized basis supplemented by a custom-developed solution. That approach, a standard supplemented by a smart addition that really helps a customer move forward, the company also carries through in both the pre- and integration processes, according to Verhoeven.

Adapt processes to current times

An efficient production and logistics environment requires a well thought-out plan. According to Verhoeven, it also requires daring to adapt processes. "What I still regularly see is that a medium-sized logistics service provider erects a large hall for a new customer, but in doing so chooses, out of habit, to deploy a standard reach truck solution. This is something they did fourteen years earlier as well. In the meantime, products have changed, dimensions have changed and contracts have become shorter."

'Good integration essential'

"No one is served by a half-baked solution," Verhoeven is clear in his stance. By this he is referring to suppliers who see companies struggling with a shortage of employees and a lack of flexibility. "A number of suppliers primarily want to realize revenue and increase market share. Without proper integration of an AMR with other components within the logistics process, you never achieve the desired efficiency gains, something that should be the focus."

Robotic solutions such as AMRs in particular are well suited to respond to what the market now demands, Verhoeven argues. "Companies do something different every day; an AMR can handle the different processes that go with it. Especially if these robots are equipped with a custom build."

Smartbox controls AMR

Companies looking to take full advantage of the flexible capabilities of robotics solutions within a production and logistics environment benefit greatly from seamless integration with other intralogistics systems in place, including WMS and ERP. "With that knowledge, we developed our Smartbox. We mount it on a roller conveyor, for example. This maintains the control of this roller conveyor, but at the same time the Smartbox controls the AMR."

Conversations as a basis for integration

Gobotty's approach is based on interviews and visits to companies. "It is clear soon enough whether we can add value. Before we start, we need to be clear what the benefits are and whether the customer is open to our approach. After one or two days of training, the system is up and running." In this, the Smartbox plays a key role. "We link it to the existing systems, such as a WMS or ERP. All systems then use the same data source. The combination of our AMRs with the Smartbox is a very good solution for eighty percent of production and logistics companies. Moreover, we rent out the solution, which also reduces risk." Aftercare is also efficiently arranged. Verhoeven: "In many cases, we can help customers by phone or online. If something is physically defective, we will of course come and fix it the same day."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Gobotty B.V..

Contact opnemen

Contact opnemen