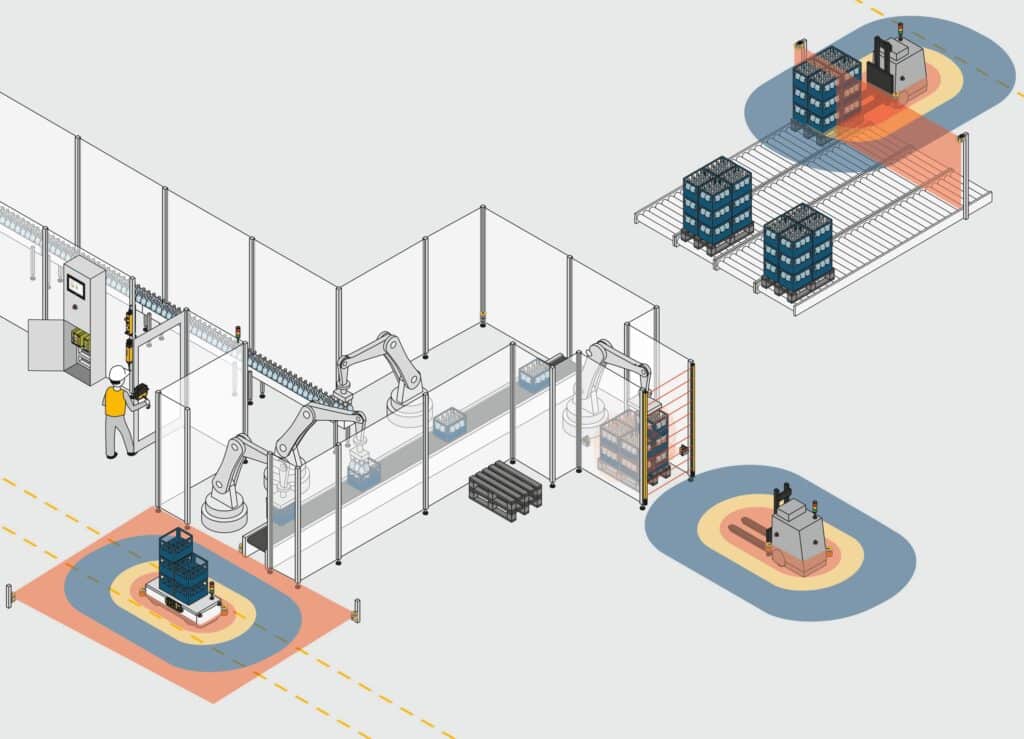

Reliable sensor technology ensures safety and productivity

“Due to personnel shortages and higher efficiency requirements, processes in warehouses are being automated at a rapid pace,” says Thomas Ploeg, sales manager at Pilz. “Sensors play a crucial role in this. “They ensure the safety of man and machine by detecting unsafe situations and, if necessary, shutting down the installation.” Pilz offers innovative solutions for this with the laser scanner PSENscan and the radar sensor PSENradar. Both systems combine precision with reliability, allowing machines such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) to operate safely and productively.

Pilz has guaranteed safe automation for more than 75 years. By investing more than 15 percent of sales in research and development, the international company offers solutions for the smart industry of the future. Ploeg explains that laser scanners and radar systems are the two most widely used sensor technologies within the warehouse and logistics sector. “Both detect based on a distance measurement, but each does so in a different way.”

Laser scanner

“Laser scanners measure distances using laser light. The big advantage of this is precision. With our laser scanner, the PSENscan, we can set up to a few millimeters precisely which area is to be secured. That makes it ideal for indoor spaces. It enables security and productive space monitoring of AGVs by detecting objects on the trajectory to be traveled. Even at high speeds, without loss of productivity.”

Up to seventy protective fields allow for highly dynamic adaptation when cornering or avoiding obstacles. Still, this technology does have limits. “Things like sunlight and dust can affect the measurement. Incidentally, if the scanner cannot read a signal properly, the system does automatically switch to a safe mode. That avoids risks, but it does mean a brief standstill.”

Radar System

“A radar system works on the basis of sonic waves, also called sound waves. This makes it insensitive to light, fog, rain, dust, dirt, sparks or vibrations. Ideal for heavy industry or in an outdoor environment.”

Pilz offers four radar sensors, two types of which allow setting asymmetrical and aisle viewing angles. This increases flexibility in integration. Especially in tight spaces where machines are close together or walkways run directly past machines, it increases productivity.

The radar system also offers another interesting advantage: “Radar sensors can distinguish between static and moving objects. As an example, let's take a robotic arm that stacks packages. To prevent the robotic arm from hitting a person when they get too close, you need a detection system that immediately disables the robotic arm in such a case. Suppose I place a box in the detection area, then the laser scanner ensures that the robot arm is permanently stopped, while a radar system restarts the machine after some time. So that avoids unnecessary downtime. One disadvantage, however, is that a radar system is somewhat less accurate. In narrower passages, it is sometimes more difficult to adjust.’

New legislation

With the arrival of the new European Machinery Regulation on Jan. 20, 2027, stricter requirements are also set for machine safety and cybersecurity. Pilz supports manufacturers in the interpretation and application of these regulations, including through risk assessments and advice on standards. They also offer varied training, from a course on ‘Basic Principles of Machine Safety’ to ‘From the Machinery Directive to the Machinery Regulation.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Pilz Netherlands.

Contact opnemen

Contact opnemen