BEUMER Group: king of the stretch hood

Pallet packing remains a process full of inefficiencies for many companies: film that doesn't fit properly, unstable pallets or products that get damaged during transport. According to Bert van Willigen, managing director of BEUMER Group Benelux, there is one system that structurally solves these problems: the BEUMER stretch hood® A. "We don't call this system the king of the stretch hood for nothing. It combines speed, stability and durability in one solution."

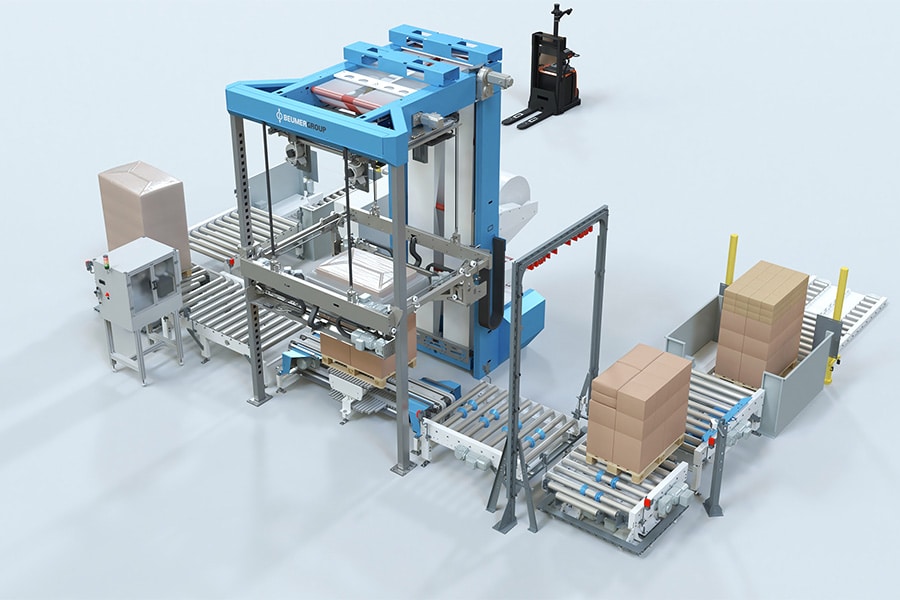

BEUMER developed the stretch hood technology decades ago and has been considered a pioneer and market leader ever since. The BEUMER stretch hood® A wraps pallets fully automatically, without heat and with minimal film. Thanks to biaxial stretch technology, the cover forms around the load in one smooth motion, regardless of shape or size. Van Willigen: "The result is a tight and stable unit that is more resistant to moisture, dust and shifting. For many companies, this means not only less use of materials, but also more security in the chain."

Why the King?

According to Van Willigen, it is the combination of performance and reliability that makes the stretch hood A unique. "The machine packs up to 120 pallets per hour and continues to do so for many years. During Logistica Next we are deliberately showing a stretch hood that has been in continuous use with a customer for ten years. By doing so, we want to show that this system is not only powerful, but also extremely robust. Other solutions come and go, but the stretch hood still stands like a king."

Benefits in practice

The managing director says the benefits of the setup are clear. "It is efficient and flexible. Handle different loads without conversion or additional settings. It is also stable and safe: vertical and horizontal stretching forces keep pallets firmly together. Sustainable and cost-saving: the stretch hood uses less film, the absence of heat leads to lower energy consumption. Visible and traceable: tight transparent film keeps barcodes and labels visible. Whether for building materials, beverages or mixed pallets, companies immediately see the gains in speed, stability and appearance."

Automation in the warehouse

The stretch hood A also fits the trend of further automation in warehouses. Van Willigen: "Forklift drivers now often lose time because they have to wait until a pallet wrapper is ready. With a stretch hood, a pallet can be supplied and retrieved automatically via a buffer system. That makes the operation faster and more efficient, especially in times of staff shortages."

The focus on automation is rapidly increasing, according to Beumer, and this is translating into more demand for the stretch hood A. Recent customers include a shoe manufacturer, an industrial supplier and a supplier of seasonal items. Van Willigen: "The investment sometimes pays for itself very quickly. Moreover, as a user you can be sure that pallets remain nicely stable. When loosening the film, no damage occurs either."

Live in action during Logistica Next

During Logistica Next 2025, the stretch hood A will take center stage at BEUMER Group's booth. Van Willigen: "Visitors can experience for themselves why we call this system the king. The demonstration with the ten-year-old machine actually says it all: this is an investment that proves itself in durability as well as reliability."