Wheel loader with CVT delivers increased productivity

The HL975A CVT is the first in Series A to combine the advantages of a traditional automatic transmission and a hydrostatic transmission in one machine.

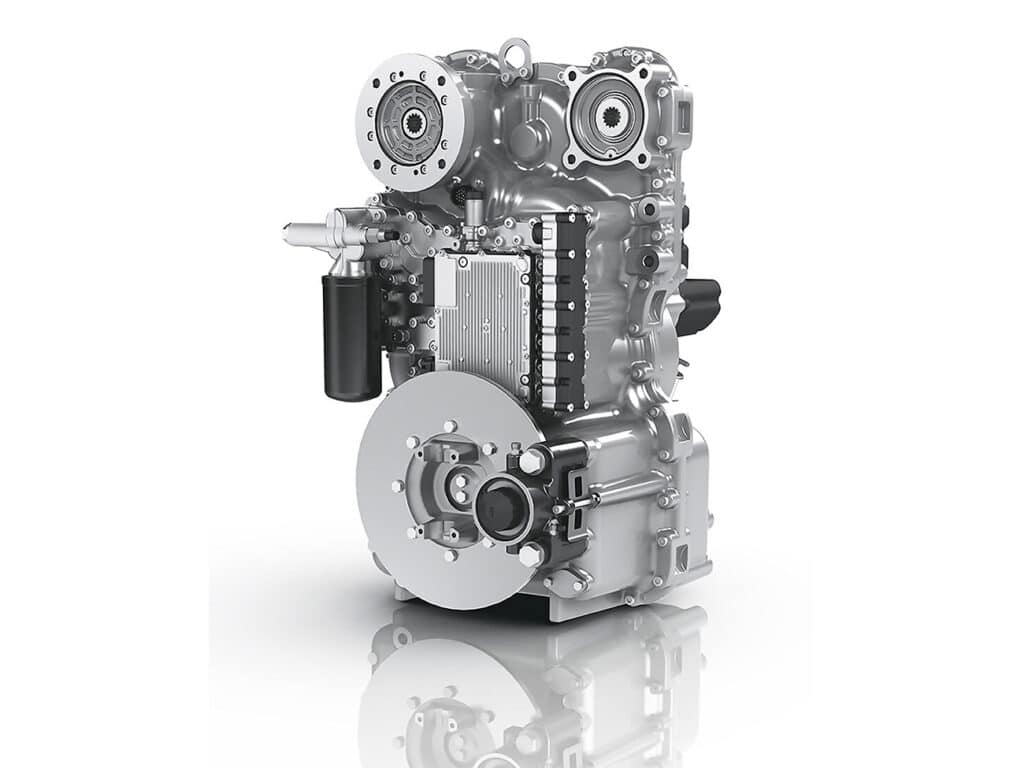

CVT stands for Continuously Variable Transmission, originally a Dutch invention. Remember those little Dafs with their Variomatic? CVT was long forgotten, but is now making a grand return, with Hyundai having the first application in a 26.5-ton wheel loader. Chosen was ZF's advanced CVT transmission. This is because it provides optimized power adjustment, continuously adjusting the ratio of hydraulic to mechanical power based on load and speed. This allows the engine speed to remain low, delivers smooth and seamless acceleration and at the same time significantly reduces fuel consumption. Depending on the application, the CVT enables fuel savings of up to 30 % compared to a conventional transmission. Mind you, without sacrificing performance or power. In addition, the CVT also acts as a brake during deceleration, reducing service brake wear and extending axle oil life.

Clean Stage V Cummins engine

New technologies such as CVT and Stage V ensure that maximum performance is achieved in an environmentally friendly way for heavy work under difficult conditions. The HL975A CVT is not only economical but also clean, thanks to the Cummins X12 diesel engine optimized for Stage V. It has almost zero emissions, allowing it to work where its predecessors were less welcome.

Users benefit from e

and increased productivity, enhanced safety, greater convenience and comfort plus improved operating time management. For example, when loading dump trucks, the operator experiences that fast and smooth acceleration combined with optimal traction greatly increases productivity. Thanks to traction control, intelligent creep function and automatic differential lock management, the operator can quickly adapt to changing conditions. What also helps is Hyundai's advanced internal weighing system technology, which is standard on this machine.

Improved comfort and safety

Of course, Hyundai also considered things like comfort and safety. For example, the spacious cab features a very comfortable, sprung seat with joysticks and intuitively operated switches, a 7-inch touchscreen monitor, Bluetooth radio and an optional door remote control, which allows the operator to open the side door remotely and safely from the ground. Due to advanced noise and vibration-reducing technology, the noise level in the cab is only 70 dB, one of the lowest in this machine category.

The machine has additional safety features such as AAVM, an advanced all-round vision system, and IMOD, an intelligent moving object detection system. Optional reverse sensors can be installed that detect obstacles during the day and night without blind spots. Audible and visible alarm functions admonish the operator to wear his seat belt, and an emergency stop switch in the seat of the chair immediately shuts off the engine when the operator is not (or no longer) in it.

Easier maintenance

Hyundai prioritized durability when developing the HL975A CVT, and the result is a robust, reliable workhorse with minimal downtime for repairs and maintenance. MCD (Machine Connected Diagnostics) allows the operator to collect and analyze a variety of data about the machine's operation, which clearly contributes to increased uptime. The engine hood opens wide for unobstructed access for cleaning and routine tasks. ECD (Engine Connected Diagnostics) supports after-sales mechanics and dealers with a diagnostic report on engine operation. This enables enhanced monitoring of engine fault codes, allowing mechanics to come to the job site with the tools needed to fix problems right on their first visit.