Saes International ensures that work continues smoothly

Anyone who thinks of equipment thinks of Saes International BV. That images of the largest demolition hammers in the world immediately spring to mind is logical. The company with branches in Weert and Tienen (B) has repeatedly made the news. However, Saes is there for all projects, from small to large. A generous range of equipment for smaller and medium-sized machines is proof of that.

Big brands for compact machines

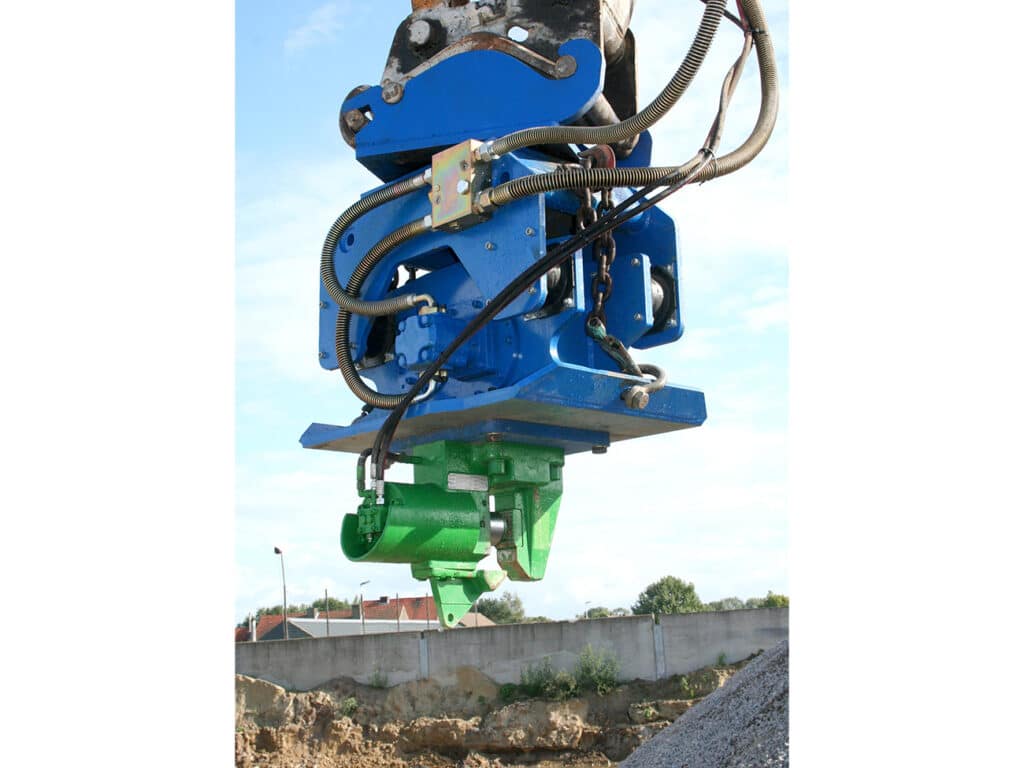

Consequently, the major brands that have joined Saes have a nice lineup of equipment that can be used on small and medium-sized projects. Epiroc comes with equipment suitable for machines from 1,000 kg and LaBounty supplies equipment for machines from 2.5 tons. VTN also serves the smaller and medium-sized machines with its range. The 100% vibratory block developed by Saes is an indispensable accessory that has become popular with contractors and machine operators based on years of expertise.

That runs like greased lightning

Saes International is a company with years of practical experience. This also makes the service offered so valuable. This involves thinking from the client's perspective. One of the most important things for contractors is to monitor the continuity of work. Downtime must be prevented at all times, and Saes responds to this by having a service team on the road, with service trucks filled to the brim with the right tools and parts. The icing on the cake, of course, is the service technician, who, with expert knowledge, carries out maintenance on site and ensures that any problems are solved.

The lubrication system developed by Saes.

The vibrating block developed in-house by Saes enjoys great fame.

Hydraulic sheet pile clamp.

Further development of existing system

A recurring task - also time-consuming - is the interim lubrication of the small pieces of equipment. In order to continue working smoothly under the often wet or dusty conditions, lubrication of parts on the demolition hammer is crucial. Saes did a further development of an existing automated lubrication system so that it can be used on the smaller pieces of equipment. This makes wear caused by insufficient lubrication or the wrong type of grease a thing of the past. A valuable addition that saves time, money and aggravation. With this solution, Saes unburdens its customers; there is always sufficient lubrication, with the right grease, at the right times. This not only benefits the progress of the project, but also ensures that the service life of the demolition hammer or attachment is significantly extended. That too may be seen as a step toward working more sustainably.