It could just happen...

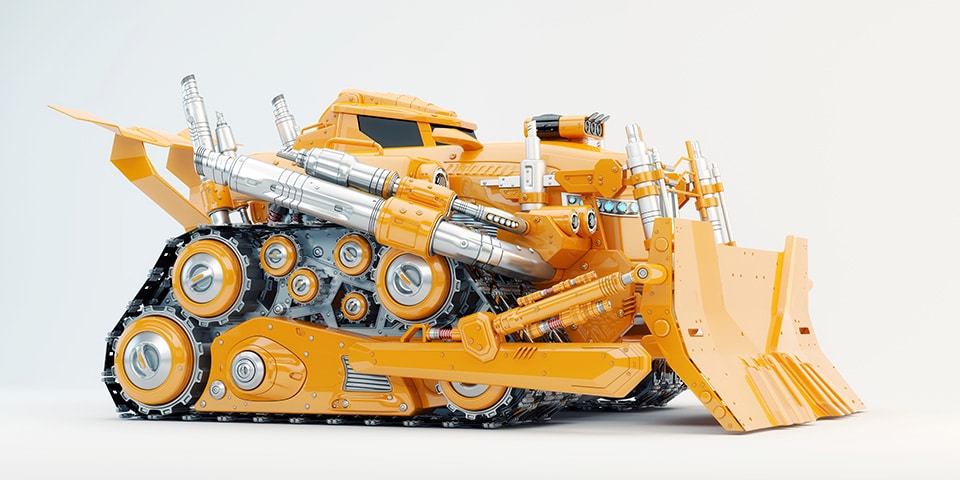

Electrification within the Earth, Road and Hydraulic Engineering industry is beginning to take off, even large machines are already running electrically as prototypes. Left and right people are already working with hydrogen even. Machines are becoming smarter and safer, for both the operator and the people on the ground. Sensor technology is providing data, suitable for immediate application, or for later analysis. There is more and more automation, and the home base is increasingly in touch with the machines (and their operators) in the field via the Cloud.

And we haven't yet mentioned the use of ever-improving GPS-linked systems, which tell us with razor-sharp precision where a machine is located and just as easily point out pipes present in the ground. Via Augmented Reality, the machine operator sees the landscape with cadastral lines drawn on a tablet. Thinking a few steps further with this information, we can almost predict what working in the Infra sector will look like in the (near) future.

Autonomy is the new magic word

With what we know now, let's look at where developments in GWW might be headed. As in the world of passenger transport and transportation, there will be an increasing desire for autonomous machines. Why? Because autonomously operating machines should in principle be safer, work can go on longer and errors due to human actions are excluded. A prerequisite for autonomously operating machines is that they be "connected," there must be a constant data connection. The rollout of the 5G network will make autonomous driving vehicles possible, including in Infra. Will a driver no longer be needed? They may not, but autonomous working will create new, different jobs. For example, on an infra project we can expect the presence of mobile "hubs" in addition to all kinds of self-operating machines. A kind of command post from which the initial monitoring is done. In case of calamities, employees can immediately intervene in the field from the Hub.

Virtual Reality or Augmented Reality glasses can be used to watch along from the autonomous machine.

Looking through the "eyes" of the machine

Whether an employee is present in a Hub behind a monitor, or somewhere in an office elsewhere in the country, Virtual Reality or Augmented Reality glasses can be used to watch from the autonomous machine. A 360˚ camera on the machine transmits the image to the operator, who can control, correct or stop the machine from a distance. An entire project can also be fully captured on video in this way, to be added later to the project file.

All machines within a project become part of a "swarm"

To individually monitor all autonomous machines on a project to prevent collisions, for example, would be a hopeless task. Autonomy, however, can only be achieved thanks to "Internet of Things," or IoT. Again, the 5G network is indispensable in this, it allows all machines within a project to be joined together within a so-called "swarm." Machines can be withdrawn (damage, maintenance, finished work) or added to the swarm at will. The machines are in contact with each other via IoT. This is necessary when work is done in succession. If machine 1 has finished its job, then machine 2 can follow it. The autonomous machines "know" from each other what their task is, when it is completed and where each machine is in the field. When many machines are working together in a small space, "machine vision," via cameras and laser detectors, can be switched. In theory, machines could operate within a few centimeters of each other without touching.

Figures must be analyzed In Real Time, after which "the system" must assess situations, provide feedback to headquarters and send commands to the machinery.

Sampling on Site

In projects where there is demolition material disposal, samples can be taken and tested on site via "Sampling on Site." Demolition waste can thus be separated on site and classified. This enables more sustainable work, as less transport is required and time is saved.

Artificial intelligence is the brains behind the operation

Autonomous machines, part of a project swarm, interacting with each other and the Hub, generate an enormous amount of metadata. Figures that must be analyzed In Real Time, after which "the system" must assess situations, provide feedback to headquarters and send commands to the machinery. This is possible thanks to artificial intelligence; there are plenty of practical examples from other industries. How utopian is the above text really? The answer: not utopian at all, the technology is already there, just waiting for standardization of protocols, agreements between machine manufacturers and the willingness of the industry to invest in it.

However, let's stay "with four wheels on the ground" for a while longer and let the digital revolution take place as it should: step by step. The current generation of train drivers will not have to worry about their jobs for a long time to come.